diddle

.30 Stingray

Posts: 475

|

Post by diddle on Aug 11, 2022 16:57:43 GMT -5

Where might I find a primer on the proper fitting and finishing of a Ronnie Wells grip frame to a Ruger Blackhawk frame? And, does anyone have words of wisdom to share with a neophyte regarding the task? I’m pretty handy with hand tools and would like to give it a try. But, I’d like to study up in advance. If this subject has been preciously answered I apologize for the inconvenience but I couldn’t find it.

|

|

|

|

Post by potatojudge on Aug 11, 2022 17:20:01 GMT -5

|

|

|

|

Post by leadhound on Aug 11, 2022 17:21:53 GMT -5

This was recommended before when asked. youtu.be/oSAIraMxv_AIn Ronnie's thread he mentions some of his techniques, such as outlining the frame with a razor blade. Not much is usually needed in the way of fitting with Ronnie's frames. Probably more work in personal profiling of the grip area. |

|

|

|

Post by Lee Martin on Aug 12, 2022 7:31:55 GMT -5

The above posts are very helpful when it comes to fitting grip frames. Just go slow and take your time. Also, for those that don't want to do it themselves, Ronnie now offers grip frame and panel fitting as a service. -Lee www.singleactions.com"Chasing perfection five shots at a time" |

|

diddle

.30 Stingray

Posts: 475

|

Post by diddle on Aug 12, 2022 9:24:15 GMT -5

Thanks, all. Very helpful.

|

|

|

|

Post by bearskinner on Aug 12, 2022 9:24:37 GMT -5

On a SS gun, you can leave it attached and remove metal, as the stainless is easy to scotchbrite back to factory look. On a blued gun, take a sharpie, and black out all the mating edges, attach the grip frame to your gun. They are all a little bit different. I used an exacting knife to scribe lines on the blacked out brass, as a point of reducing metal to that point. First one took me 2 days. After seeing how simple and easy it is, I now use a flap wheel on a grinder, and a DA sander, to do most of the work. I can for one in under 2 hours, including sanding grip panels (DEFINATELY have Ronnie fit your panels for final sanding to your hand.)   |

|

|

|

Post by potatojudge on Aug 12, 2022 9:55:25 GMT -5

Use all the screws when fitting the frame

If you try to just use one or two you might find it will shift and your frame will end up undersized.

A spare set of sacrificial grip frame screws will keep your good ones clean

|

|

rocdoc

.30 Stingray

Posts: 133

|

Post by rocdoc on Aug 12, 2022 17:24:46 GMT -5

Good advice

|

|

|

|

Post by bigbore5 on Aug 12, 2022 21:23:13 GMT -5

Invest in a band file. Basically it's a hand held band sander. Belts are narrow (3/8" to 3/4"), are readily available, and come in grits from 40 to 1200. Really saves time and if you think it through looking at one, it's easy to see where the band is supported for keeping flats flat and unsupported for contours.

Amazon, eBay, and others have some for less than $50. They're ok for this type of work. I've tried one of the cheap ones and it worked fine. It's not my metabo, but that's a highend tool for work.

Once you use one, you'll find many other uses. I fit my grips with one too.

|

|

DutchV

.30 Stingray

Posts: 166

|

Post by DutchV on Aug 15, 2022 17:33:20 GMT -5

Invest in a band file. Basically it's a hand held band sander. Belts are narrow (3/8" to 3/4"), are readily available, and come in grits from 40 to 1200. Really saves time and if you think it through looking at one, it's easy to see where the band is supported for keeping flats flat and unsupported for contours. Amazon, eBay, and others have some for less than $50. They're ok for this type of work. I've tried one of the cheap ones and it worked fine. It's not my metabo, but that's a highend tool for work. Once you use one, you'll find many other uses. I fit my grips with one too. Thanks for the tip. I didn't know these existed until now. |

|

rocdoc

.30 Stingray

Posts: 133

|

Post by rocdoc on Aug 15, 2022 20:04:07 GMT -5

I got one of those sanders earlier in the summer and a couple packs of belts, have not had a chance to use it yet, seems like a good tool. I have been fitting frames with files and emory paper with good results for a couple years.

|

|

edk

.375 Atomic

Posts: 1,162

|

Post by edk on Aug 15, 2022 20:47:00 GMT -5

There have been many examples posted of great workmanship on behalf of forum members fitting Wells grip frames. One glitch I've observed repeatedly is by those fitting Wells Bisley grip frames to what must have been standard Blackhawk/Super Blackhawk cylinder frames. Those cylinder frames seem to come from the factory with the ears descending at a steep angle. Then, when fitted with a Bisley grip frame with the profile of the grip frame intersecting the cylinder frame at a more shallow angle, it is not possible to have the line of the backstrap follow a continuous curve without an inflection point - hence the glitch. No easy fix for this except TIG welding the cylinder frame I would think.

|

|

|

|

Post by rkcohen on Aug 16, 2022 9:52:35 GMT -5

fwiw, there's a post on youtube that shows power senior fitting a #5 (ish) grip to a frame worth looking at...

|

|

|

|

Post by harveylogan on Aug 16, 2022 10:12:55 GMT -5

CAUTION!!!RW grip frames are made from fairly soft brass, it is not HARD to remove material. The Cast frames from Qualite/ MK (no longer manufactured) and others, are harder brass. I would suggest investing in this set of Diamond Flat Files, they help in keeping the flats flat, and can be used to knock off the edge’s. Good quality, ~$20 www.amazon.com/gp/product/B008CO87WE/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

|

|

|

|

Post by RDW on Aug 24, 2022 18:23:59 GMT -5

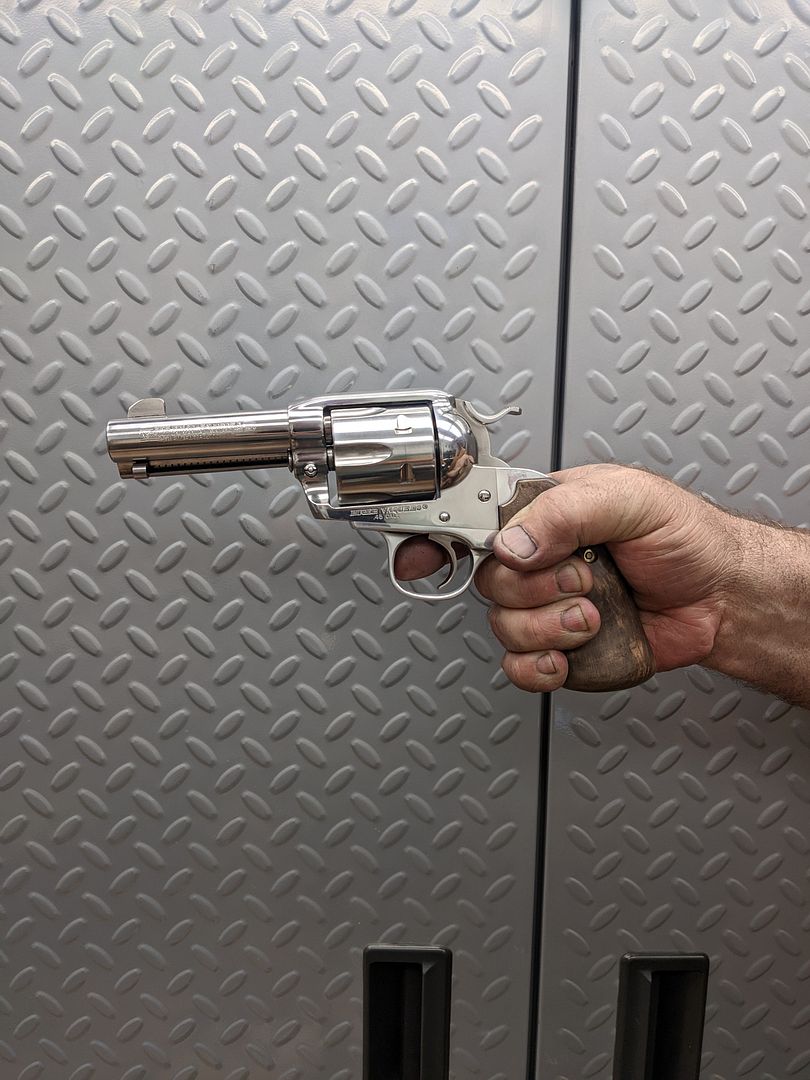

There have been many examples posted of great workmanship on behalf of forum members fitting Wells grip frames. One glitch I've observed repeatedly is by those fitting Wells Bisley grip frames to what must have been standard Blackhawk/Super Blackhawk cylinder frames. Those cylinder frames seem to come from the factory with the ears descending at a steep angle. Then, when fitted with a Bisley grip frame with the profile of the grip frame intersecting the cylinder frame at a more shallow angle, it is not possible to have the line of the backstrap follow a continuous curve without an inflection point - hence the glitch. No easy fix for this except TIG welding the cylinder frame I would think. Found it. I have been looking for this thread because of this very issue. Guys alot of this requires patience and a little finesse. I believe this is what you were refering to EDK. A smooth transition of frame to grip frame? .jpeg) .jpeg) This is a new model midframe flat top. They come with a tall back so its easier to manipulate the angle. The next one is a Vaquero in stainless and i had to bring the taper down because it was way tall at the front and tapered down alot rearward. If i would have maintained the angle we would have cut the whole backstrap off.    |

|