|

|

Post by RDW on Aug 24, 2022 18:26:21 GMT -5

That Big ole Tater judge felt great on this 45 LC shorty Mc smackarooney by the way.

|

|

edk

.375 Atomic

Posts: 1,162

|

Post by edk on Aug 25, 2022 13:13:48 GMT -5

Ronnie, that would be correct and what I was referring to. Some are missing the fact that you don't want your grip frame looking like this Reeder example from an active thread in the gunsmithing section:  It doesn't matter in the end how well the grip frame mates to the ears or how well the grips fit there grip frame. If your Bisley resembles the above example it has deviated considerably from what even the factory produces. |

|

|

|

Post by Gunny268 on Sept 15, 2022 21:01:35 GMT -5

On this particular aspect of fitting the grip frame to revolver frame I'd just like to quote David Bradshaw, "Final blending of grip frame to frame requires... remove a tiny bit & fit, remove a tiny bit & fit, et cetera. I've tried to follow his advice and am happy with the outcome.  |

|

|

|

Post by bushog on Sept 15, 2022 21:41:53 GMT -5

On this particular aspect of fitting the grip frame to revolver frame I'd just like to quote David Bradshaw, "Final blending of grip frame to frame requires... remove a tiny bit & fit, remove a tiny bit & fit, et cetera. I've tried to follow his advice and am happy with the outcome.  you file the frame itself to get that smooth transition? |

|

|

|

Post by Gunny268 on Sept 15, 2022 23:44:40 GMT -5

Bushy, I don't have access to anyone that can reblue a frame. All I could do was sand and fit, sand and refit the brass grip frame about 20 times or so (going to finer grit) until I was happy with the angles and height of the grip frame "ears". NOTE: I'm no gunsmith and I shoot this pistol much more often than I work on its "customization". And that's because there are a lot of details (knowledge) to the work that I am having to hunt down or figure out. So, I get to shoot it until I'm ready to take on the processes for the next step in its "customization."  |

|

|

|

Post by leadhound on Sept 16, 2022 0:01:04 GMT -5

On this particular aspect of fitting the grip frame to revolver frame I'd just like to quote David Bradshaw, "Final blending of grip frame to frame requires... remove a tiny bit & fit, remove a tiny bit & fit, et cetera. I've tried to follow his advice and am happy with the outcome.  you file the frame itself to get that smooth transition? Thinkin maybe it was already a Bisley, or a newer Blackhawk with the taller ears. |

|

|

|

Post by bushog on Sept 16, 2022 8:51:36 GMT -5

Bushy, I don't have access to anyone that can reblue a frame. All I could do was sand and fit, sand and refit the brass grip frame about 20 times or so (going to finer grit) until I was happy with the angles and height of the grip frame "ears". NOTE: I'm no gunsmith and I shoot this pistol much more often than I work on its "customization". And that's because there are a lot of details (knowledge) to the work that I am having to hunt down or figure out. So, I get to shoot it until I'm ready to take on the processes for the next step in its "customization."  Nice job and it looks great! |

|

|

|

Post by longoval on Sept 16, 2022 9:16:29 GMT -5

Ronnie, that would be correct and what I was referring to. Some are missing the fact that you don't want your grip frame looking like this Reeder example from an active thread in the gunsmithing section:  It doesn't matter in the end how well the grip frame mates to the ears or how well the grips fit there grip frame. If your Bisley resembles the above example it has deviated considerably from what even the factory produces. A couple things... 1. The pictured Reeder has much bigger cosmetic issues than the grip frame ears transition. 2. Ronnie Wells does a great job of avoiding the problem you show. I had him fit a couple of mine and they have very good transitions. Mine started as plow handles and Ronnie was able to make it look right.  |

|

|

|

Post by Gunny268 on Sept 16, 2022 13:57:04 GMT -5

Longoval, Is that a Wells #5? Looks great! I picked one up on Ronnie's "Sale" page for my (new to me) 45 Colt Flattop convertible. (One day soon?) I hope to get going on its "customization." But for now, I guess I'll just have to keep shooting it "as is." OH DARN!

|

|

|

|

Post by longoval on Sept 16, 2022 13:59:12 GMT -5

Its actually a Wells #9. A version of the #5 for large hands.

|

|

|

|

Post by bradshaw on Sept 17, 2022 8:30:09 GMT -5

Gunny.... beautiful work you’ve done, fitting the RWGF. Craftsman such as Fermin, Lee, and Ronnie, not to mention Hamilton Bowen, Jim Stroh, and custom smiths who mascot Singleactions, are far better with a Mill Bastard File in their sleep than I am at the height of my glory. These guys can file a ball bearing from a cube of steel. For me, the file is a minimal-use tool. My primary crutches are a belt sander and Dremel too. For hand sanding, my main props consist of wet/dry----around 400 grit----with plenty water to keep abrasive flushed. Wetted wet/dry paper lasts infinitely longer than wet/dry run dry. Not only that, flushing keeps particulates from embedding.

The trigger guard can be done with paper on your finger, but a small rotary grinder with 1/2” sanding drum is so much faster. Final sand & polish of course by hand only. I don’t have a buffing wheel so don’t use one. Even so, the buffing wheel is a dangerous device without serious practice. Once, walking through the Thompson/Center shop with Warren Center, he said it takes more time to train a polisher than for any other operation.

To reduce the sides of the grip frame, I start with a flat block of wood, steel, or brass on the work bench. Carefully move the flat of the grip frame back & forth on wetted wet/dry paper. I’ll even use the belt sander briefly if there is a lot of material. Again, remove a tiny bit & fit, etc.

Ruger grip frame screws

The head on a Ruger grip grame screw tends to be eccentric to the shaft. This will drive you nuts when re-installing the factory grip frame. Why? Because, as it is tightened, the high side of the screw head shifts grip frame into misalignment with frame. The grip frame oscillates on frame as it is tightened. And you wonder why it’s nearly impossible to match factory alignment.

RWGF

Another unsung advantage of the Ronnie Wells Grip Frame, screw counterbores accommodate eccentricity of the Ruger screw head.

David Bradshaw

|

|

edk

.375 Atomic

Posts: 1,162

|

Post by edk on Sept 18, 2022 16:58:28 GMT -5

A couple things... 1. The pictured Reeder has much bigger cosmetic issues than the grip frame ears transition. 2. Ronnie Wells does a great job of avoiding the problem you show. I had him fit a couple of mine and they have very good transitions. Mine started as plow handles and Ronnie was able to make it look right. Re your #1: That may be so however it serves as an excellent example of how not to fit a Bisley grip frame. Re your #2: Your gripframe looks very good - as does that of Gunny268. My comment on page 1 of this thread was to the effect of "many (if not most) Bisley aftermarket grip frames are poorly fitted". It was not directed at Ronnie Wells or anyone else in particular. In fact point #1 demonstrates the fact that home gunsmiths aside, even some pros cannot get it right. I suspect a large part of that is starting with a cylinder frame originally fitted with a Blackhawk/SuperBlackhawk grip frame at the factory having the ears depart the recoil shield at a steep angle. |

|

|

|

Post by RDW on Sept 18, 2022 19:08:17 GMT -5

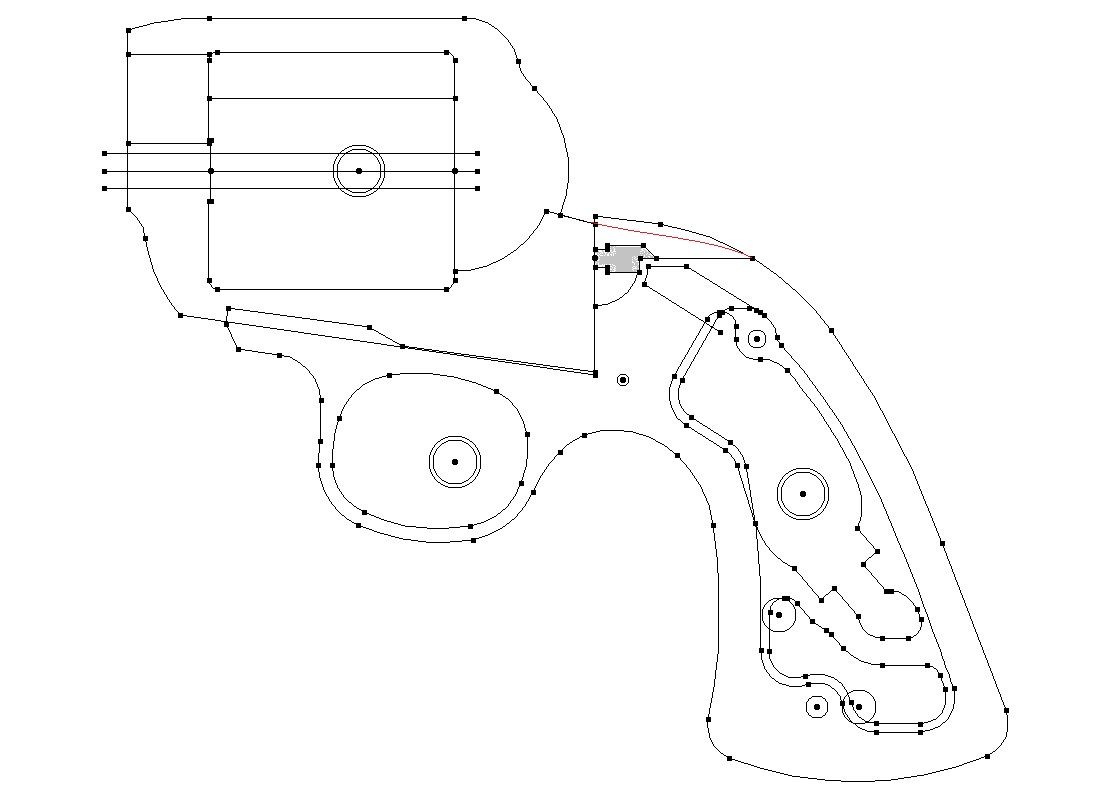

Hey EDK I dont think anyone was offended. I sure wasnt Buddy, i was Flattered. I do have a pet peive though when it comes to that transition from Main frame to grip frame. And one of the little perks about machined versus Cast is that i put a .220" bored hole for the screw head to fit into in the back of the grip frame. Just enough clearance to clear the boss on the grip frame. The cast has this great big Cavernous void that is easy to cut into when you are trying to transition smoothly. All of these main frames thru out the years were all over the place as far as how high that main frame back and yes the bisleys tend to be straighter and taller but you dont have to worry about cutting thru the top of the back strap with mine as you do with the cast. I love Bradshaws french curve and have quit welding up my main frames. I just blend her on in a smidge and i think they look nice when they just flow into the Back of the main frame. John Linebaugh told me recently about a frame he had cut thru and called them oiling holes. Hahaha. I liked his recovery. If you look at the shaded grey area on my drawing you can see just how much room there actually is. And the little Red line is representative as to how i cut her down and transition. The shaded area is the actuall hole for the screws. This is actual machine programming geometry here so it is an accurate depiction. Also having no major clearance on the screw makes alignment a breeze when you are sockin it all together. In the 80s i did cross thread a couple on factory Bisleys. Had to find all the peices that i chunked across the maintenace department at Baker Oil Tools and rethread the Darn thang. Sure pissed me off. Hahahaha. Go thru all that work and then that happens. Glad i dont have a temper any more.wink wink, (SHUT UP FERMIN) I know your going to comment. Hope this helps anyone interested. R  By The way this is Bobby Tylers New BO TY Version of the Keith 5. Bitchin aint it? |

|

|

|

Post by RDW on Sept 18, 2022 19:11:34 GMT -5

On this particular aspect of fitting the grip frame to revolver frame I'd just like to quote David Bradshaw, "Final blending of grip frame to frame requires... remove a tiny bit & fit, remove a tiny bit & fit, et cetera. I've tried to follow his advice and am happy with the outcome.  Gunny that is as Profesional a fitting job as could ever be done Buddy. Well Done man. Well Done. R |

|

edk

.375 Atomic

Posts: 1,162

|

Post by edk on Sept 19, 2022 6:55:15 GMT -5

Ronnie, that picture is truly worth 1000 words. I fear too many are fitting in a fashion resembling the green line I added. Everyone fitting one of your grip frames needs to see your picture!  |

|