|

|

Post by bushog on May 13, 2021 7:22:30 GMT -5

Will these “drop in” like the Clements parts o will they need fitting like the Powers hammers?

This question has been holding me back.

|

|

|

|

Post by RDW on May 14, 2021 11:38:40 GMT -5

Any updates/ETA on the hammers? Yes! Been hackin away here, but have had a few conversations with Clements, Linebaugh and Harton during this process and have made some serious improvements based on the four of our experiences and dreams! With that being said i apologize for not staying on line and continually updating but as i told a gentleman recently, I CAN DO OR I CAN TEACH! This has been a real journey in manufacturing because there are so many ways to improve the process. I wont bore you with details but i can assure you this will pay off. For those of you that have anteed up here and helped me finance this journey, Hang in there you will receive much more than you purchased. I have a nice list of all of you that i am going to get to test out some ideas and newer creations. Michael is putting together a list of phone numbers of all the depositees of hammers and triggers and i am going to call you individually to see what else we have got here that is not on the list that turns you on and add them to what you receive. I am really excited about this guys. I am really starting to see the results of the countless hours of testing and geometry manipulation here. I want t o be able to guaranty your satisfaction with the product you have ordered. Here is a picture of what my programming desk has looked like for the past couple of months. As you can see, weve been busy....  For the most part we are done with the changes so now we are in the heat treating and finishing stage for about fifty percent of the orders but its moving well. Getting close guys, Hang in there! I just want them perfect! R |

|

|

|

Post by blacktailslayer on May 14, 2021 13:37:31 GMT -5

Excellent!

Don D.

|

|

lobo

.327 Meteor

Location: SE Mississippi

Location: SE Mississippi

Posts: 552

|

Post by lobo on May 15, 2021 23:15:54 GMT -5

Thanks for the update!! Beautiful work!!

|

|

|

|

Post by dougader on May 16, 2021 13:33:42 GMT -5

So very exciting!

|

|

|

|

Post by RDW on May 18, 2021 18:20:48 GMT -5

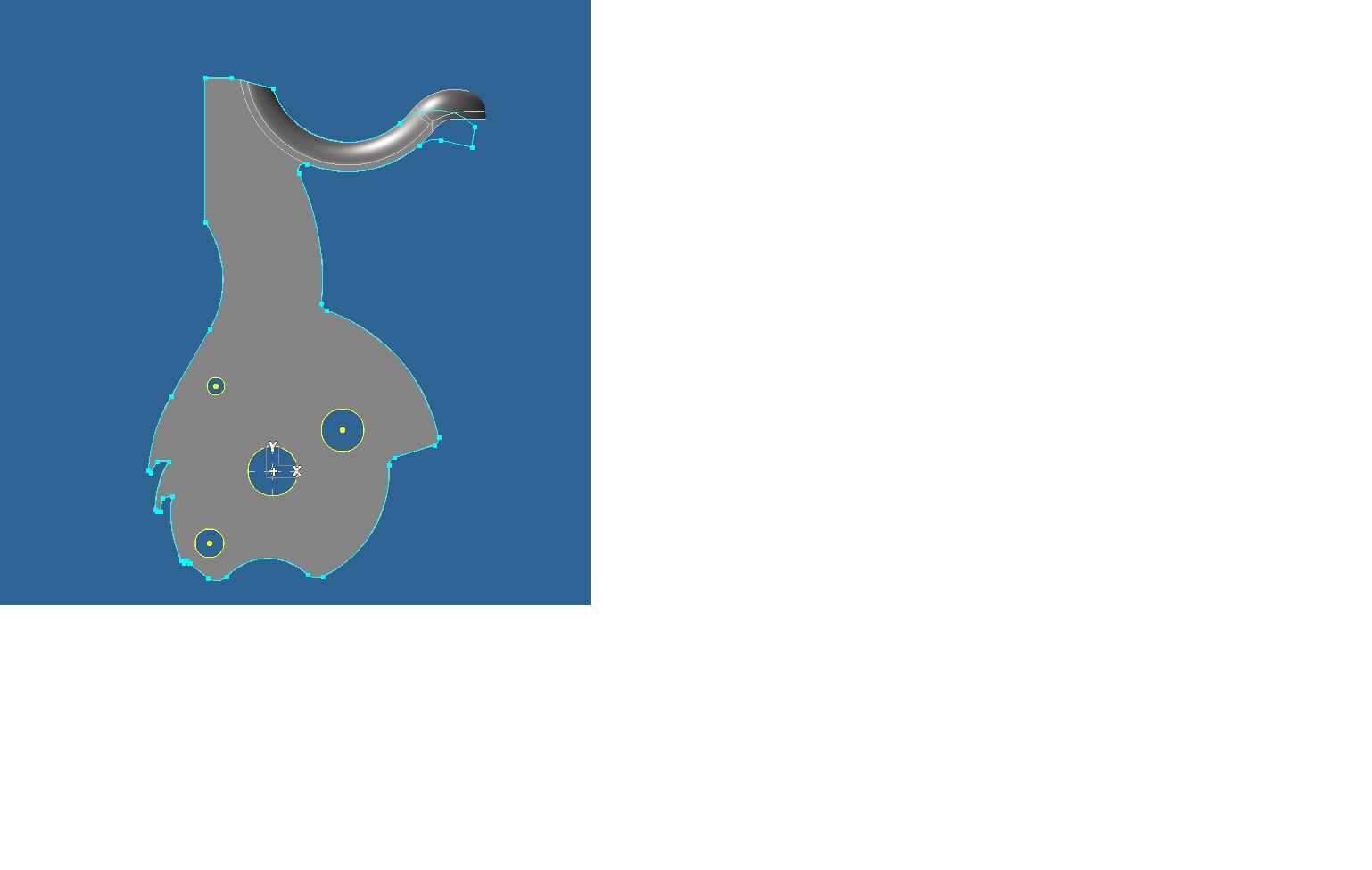

Ok Fellas. Like all situations where you have plopped down your Hard Earned cash, You wanna know that you didnt just throw it away. Let me assure you i have beat my brains out on these Hammers because of all the manufacturing woes that come along with a project like this. I have seen certain comments such as (many have tried But.......) and i completely understand. To many of us have taken a chance on some Num nut Jake leg out there and got taken to the cleaners. I know i have and that is the main reason that i have spent so much money and time to acquire the knowledge and the equipment to just do it all myself. However as many of you have noticed that have gotten to know me. I AM SERIOUS ABOUT WHATEVER I AM DOING! So with that being said you need some answers, here they are. This is what i have been doing with all of the geometry that i got from mr Clements and all of the experimentation. One of the many things i have noticed about all of these Hammers is that their are major inconsistency's with the hole patterns in the hammers through out the years. Those hole patterns are everything when it comes to the repetitive function of the Revolver. My main concern with this project was carry up and lockup timing! A major issue can be seen when you swap hammers and triggers between revolvers. One hammer may actually lock in to the cocked position before the cylinder has latched into Battery. I have discussed this with the 3 Gentlemen who we all have come to trust in custom revolvers smithing world. Linebaugh, Harton and Clements. When you buy a Hammer or a trigger unless you have absolute consistancy between the hole pattern on the frame, a pawl or arm, and the Ratchet, No one is going to be able to make an absolute just drop it in and everything will be hunky dory. I have seen so much difference in the factory stuff that anything would seem to be somewhat of an improvement. So lets talk about Carry up. If you smack that ole hammer back with some decent speed or pressure for lack of a better way to describe it, The inertia and rotating mass of the cylinder will usually carry the cylinder in to complete latched lockup. However, picture this! You are sitting in your favorite stand and MR BUCK with two oak trees growing out of the top of his massive head steps out in front of you unexpectedly and he is looking in your direction and you need to cock that mammy around real slow as to not alarm him, And your timing is off. The hammer cocks and the cylinder is not quite there yet. So you have to give the cylinder a touch or over cock the hell out of the hammer to get it in to Battery. Now maybe im thinking to hard about this but i just cant help it. So i Ran this by them and seemed to get a large measure of agreement that what i am going to describe or explain was a good idea. Most of the hands that i receive on all my builds most generally are worn. The hand seems to be the weak link in all of the carry ups. Here is the first picture that will explain the changes we have made to improve this. The blue Line shows you the lower hand Holes location. It is .125 in diameter and you will notice a Black hole and center point and a Red one as well. The black hole represents the original location. The Red is the new. We moved it downward along the axis of the line that you see leading into the hand hole from the center of the Hammers Main rotating center point exactly .010 thousandths. Then you will notice that the red center point of the new location has then been moved up .004 thousandths from there. Study it. you will see it! .jpg) Gentlemen the significance of that move is to change the leverage angle and travel of the hand. it gradually increases just a smidge as the hammer is wheeled back. In the next pic is a closeup comparison of the two Patterns layered over each other. .jpg) The red circle is around the starting point of the hand. Notice they are in the same location ready to engage the ratchet. Both of them at .7241 from the center of the hammer. The green shows you the difference in the hole locations as well as the slight repositioning of the hand. The next pic is of the hammer at 52 degrees in the cocked position. .jpg) you will notice that the old hammer raises the hand up to 1.0646" and that the new raises it to 1.0745". A gain of .0099. The top has now disengaged the ratchet and the lower spur has done the finish work on the ratchet. It has gained .010 thou of travel making sure that the cylinder carryies up to lock the cylinder into battery. Its not much but it has proven so far on twenty random rugers to carry all the way up even with a sloppy pawl. 6 of the test rugers needed a tickle on the lower spur to bring it in just right. they were fairly tight however the others were well worn. My theory here is that if you have some worn components it is better to have to much meat on the lower spur of the hand that can be easily taken down with a file. If you can install a hammer you can easily shave a smidge off of the lower spur! However if you install the hammer in to a SA with a worn ratchet and hand it may not always carry up with out adding material to the hand. Unless you want to take a chance with a hammer and flatten it a bit or have reasonable access to a TIG. You might not be happy. Its easier to remove material than to add it. For those of you who dont get into the details, We totally understand. Its a lot to take in. For the most part i have seen nothing but the most serious of shooters and Ruger aficionados on this forum and i appreciate all of you. Especially those that have taken a chance on my grip frames and now the Hammers. I will stop at nothing to ensure that you get a quality product that will enhance your shooting experiance! I just thought it was time to explain what we have been doing here and to say hang in there. No body wants this to be more successful that myself. It has been a life long dream and dammit im just gonna doit. Hahaha. If you have any questions please feel free to call or message. Thanks guys. R |

|

Bagby

.30 Stingray

Posts: 168

|

Post by Bagby on May 18, 2021 19:37:25 GMT -5

Very cool Ronnie. My limited experience mirrors what you are saying about inconsistency with the hole patterns. I have some old models that I have swapped around parts and pieces while teaching myself how they go together, and how the parts interact. Very cool to see what I was experiencing laid out so clearly.

Just can’t wait to get my hands on some of these parts.

Jonathan.

|

|

|

|

Post by pacecars on May 18, 2021 19:58:26 GMT -5

Thanks for the update. I told John Powers I am not in a hurry and waiting on one of your hammers is no problem and will be worth the wait

|

|

|

|

Post by bradshaw on May 19, 2021 10:59:37 GMT -5

A continuing facet of my discussions with Ronnie involves steel & heat treatment QUALITY of factory hammers and triggers. Time on the Mountain, i.e. Firing Line----reveals Ruger steel & heat treatment, both chrome-moly & stainless----to hold a trigger job longer than other single actions. While I declare it so, I cannot provide the metallurgical explanation. Ronnie agrees worthy my assessment, then lays out the reason why. Parts by David Clements may pass the same test of time----Ronnie says Clements is a wealth of serious knowledge, "serious knowledge" defined as incorporating experience----but I am talking factory.

When Ruger released the stainless Super Blackhawk in 1983, I stated in print that a clean-breaking 1-pound pull didn’t last as long as a trigger job done on Ruger’s chrome-moly hammer & trigger. I was splitting hairs. Yet I must have thrown some lead to conclude a difference. I sold a KS411N Silver Hornpipe to IHMSA silhouetter Cookie Cookson. It was shot plenty before he bought it. Cookie campaigned the Silver Hornpipe on steel, and took it to an old silhouette buddy, retired Border Patrolman Major Golden. When I visited Golden in Tombstone, he said, “Your Silver Hornpipe is a shooter, Hoss!”

Unless someone competes silhouette at the highest level, they are exceedingly unlikely to ever detect a difference between stainless and blued Ruger hammers & triggers.

CARRY-UP on Ruger New Model single actions is notoriously slow. As the hammer is cocked, the CYLINDER LATCH (bolt) drops earlier than necessary. Yet, the hammer reaches FULL COCK before the bolt locks the rotating cylinder. As Wells describes, to s-l-o-w-l-y cock the hammer risks taking a shot from an out-of-battery chamber. By very-slightly relocating the pawl pivot hole in his hammer, Wells advances carry-up for better timing. This is just one detail which sets a RWGF hammer apart.

Wells can also angle the Bisley spur a taste higher to avoid fierce hammer bite from a .475 or .500. Or, a Super Blackhawk spur on a Bisley hammer, etc.

David Bradshaw

|

|

|

|

Post by RDW on May 19, 2021 16:33:53 GMT -5

Oh Ya . I forgot to mention another Hammer that works well with the big hand guys, or those of you who would rather have the rear spur of the bisley hammer rotated up an 1/8 of an inch for backstrap to thumbweb clearance. My Bradshaw with a Bisley hammer will just barely cock because the backstrap is moved rearward 3/16s of an inch. The BRADHAM will cure that! Here is an example. The Blue lines represent the current spur placement. Notice the BradHam is a smidge taller. ( 1/8") For those of you who are not familiar with a smidge. That translates to Nats Behind or about yeah bit. In Texas A smidge is a Nats Ass and a smidgeon is just a wee bit more. Hahaha. My first attempt came out to be .1217" taller and i hate jacked up numbers so number two came out just right. 1/8"   ***** Simply handsome, Ronnie. Almost a marriage of Super Blackhawk and Bisley hammer spurs. Apparent advantages: * Clearance for shooter’s hand. * Reduce chance of bite to bone or web at base of thumb----from rounds producing severe recoil. * Increase cocking leverage. These advantages may prove more dramatic with the factory Bisley. The Bradshaw Bisley made my middle finger forget the bashing from heavy loads dwith the Ruger Bisley. David Bradshaw |

|

|

|

Post by kings6 on Jun 15, 2021 23:02:59 GMT -5

Any updates on the hammer orders Ronnie?

|

|

|

|

Post by dougader on Jul 12, 2021 12:56:15 GMT -5

I was on the phone with a couple guys just now, including 2Dogs/Fermin. Just to pass on, Ronnie is working 7 days a week 16-18 hours a day trying to get things done.

I know how it is wanting to know if there is a new ETA on things, just so you can schedule projects with gunsmiths, etc. (At least, that is my only concern). But I know Ronnie is working to make these as perfect as possible for us.

|

|

rufus

.30 Stingray

Posts: 454

|

Post by rufus on Jan 8, 2022 16:40:29 GMT -5

For us new guys, is the purpose of this to obtain parts to convert 3 screws back to the original design AFTER they had been converted to the transfer bar system ?

Thanks

David

|

|

|

|

Post by 2 Dogs on Jan 8, 2022 17:34:41 GMT -5

For us new guys, is the purpose of this to obtain parts to convert 3 screws back to the original design AFTER they had been converted to the transfer bar system ? Thanks David That’s one purpose. Another would be to create a sixgun that has never been made before such as an old model bisley Single Six. As many reasons as there are different parts. |

|

|

|

Post by bigbore5 on Jan 9, 2022 13:41:57 GMT -5

Or an old model 357 with wide spur trigger and super blackhawk hammer fitted with a biznana frame when Ronnie starts shipping out the old model version. He's been working 7 days a week for awhile now. He tells me he's got the new machines running and the heat treatment down so it won't be too much longer until we'll start seeing them. The wait has been hard, but the hardest part will be deciding which version to get.

|

|