Bagby

.30 Stingray

Posts: 168

|

Post by Bagby on Sept 16, 2020 8:08:15 GMT -5

Well finally got some progress made on my No.5. Ended up Changing directions on the project. Was planning on using a protected sight OM 357 I had. However I picked up a nice OM 357 flattop And the decision was made for me. The flattop and the No.5 just go together so well to my eye. Here is a progress picture.  Got it almost flush except for where the back strap meets the frame. Next thing is to bring the back strap down to meet the frame and blend them together. Then on to contouring the grip panels. Thanks, Jonathan. |

|

|

|

Post by RDW on Sept 16, 2020 13:34:57 GMT -5

lookin Great Jonathon!

What are you gonna put on it for panels brother?

|

|

|

|

Post by RDW on Sept 16, 2020 13:58:04 GMT -5

Reason im asking Mr Bagby, is because this last batch of Walnut i got has some really nice stuff in it! Matt at Tyler Gun Works has been installing some of these and is a very talented young man. He seems to enjoy it as well which is very important. He has done a great job of fitting it. Hell its not even finished and allready looks great, as yours does as well. I wish i would have known he was putting a Blackhawk trigger on it though, i would have sent one with blackhawk trigger cutout option. Both will work well but the Blackhawk trigger cutout for bisley trigger guard will get rid of the gap at the front of the trigger, which is necessary for the bisley trigger! sure is looking good though!     |

|

djoch

.240 Incinerator

Posts: 30

|

Post by djoch on Sept 16, 2020 15:33:36 GMT -5

Those grip panels look great!

|

|

Bagby

.30 Stingray

Posts: 168

|

Post by Bagby on Sept 16, 2020 16:55:43 GMT -5

lookin Great Jonathon! What are you gonna put on it for panels brother? I’ve got a set of your nice black micarta panels that I will be fitting. I might have to try some walnut once I get the micarta fitted. Thanks, Jonathan. |

|

rhino

.30 Stingray

Posts: 213

|

Post by rhino on Sept 19, 2020 6:26:42 GMT -5

Those grips are nice Ronnie, I'm going to have to start an auto payment Monthly for you. 😂

|

|

|

|

Post by RDW on Sept 19, 2020 10:05:39 GMT -5

Those grips are nice Ronnie, I'm going to have to start an auto payment Monthly for you. 😂 Shoot Sam, You in like Flynn Brother. just wait till you see the Cocobolo i made for your Wells # 9 and Potatojudge, Bradshaw and dave clements this week. This stuff is beautiful, hard,and just totally PIMPY man!  |

|

|

|

Post by unclezeb on Sept 19, 2020 19:00:50 GMT -5

Clean looking slabs Ronnie, have you messed with desert ironwood yet? I’m curious to how your machines will chew it up I always forget to ask when I get the chance to talk to you.

|

|

|

|

Post by RDW on Sept 20, 2020 10:03:02 GMT -5

Clean looking slabs Ronnie, have you messed with desert ironwood yet? I’m curious to how your machines will chew it up I always forget to ask when I get the chance to talk to you. It mows the hell out of it! I have gone an unconventional route with tooling. I have found that the diamond coating on a quality carbide four flute will just eat it like PAC MAN! Clean cuts and small shavings is the ticket! R |

|

rhino

.30 Stingray

Posts: 213

|

Post by rhino on Sept 21, 2020 10:10:44 GMT -5

Those grips are nice Ronnie, I'm going to have to start an auto payment Monthly for you. 😂 Shoot Sam, You in like Flynn Brother. just wait till you see the Cocobolo i made for your Wells # 9 and Potatojudge, Bradshaw and dave clements this week. This stuff is beautiful, hard,and just totally PIMPY man!  Oh man, those are sharp looking! Cocobolo wood is hard as wood pecker lips, good grain and color too. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Sept 21, 2020 20:51:34 GMT -5

Excellent work all around. Love the DIY type grip panels too. Have guys been mounting the aluminum grip frames on stainless guns? Would love to see pics. Really like the kbird bisley-birdshead love child.

|

|

|

|

Post by unclezeb on Sept 22, 2020 21:45:28 GMT -5

Just received my No. 5 grip frame and goodies and figured I’d give a cash money review. The grip frame snapped into my new model blackhawk 45lc better then the factory grip frame. At the most I’ve have take to a 1/16 off for fitting. All this just like Ronnie says can be done by hand by the average guy. The prefit grips he makes for the grips are very snug in a good way. Same thing a little sandpaper and you can flush them up with the grip frame no problem. Take some sand paper and maybe a rasp to contour them them to your, money in the bank.

Ronnie, excellent work really blew my socks off. I’m going to have to order another frame real soon for my 30 carbine jack rabbit blaster. That frankenfab looks damn cool.

|

|

|

|

Post by Gunny268 on Sept 23, 2020 19:58:03 GMT -5

Last Monday I too received "the package" from RW and I can say that the gentleman far exceeded any expectations.

I too would like to add myself to those who appreciate and value his work for single action shooters.

|

|

|

|

Post by olongjohnson on Sept 29, 2020 10:25:48 GMT -5

Greetings, all! I'm not big on the "Hello World" thread, so here's my "Hello World" post to this forum. I have checked out some info on this site before, but joined up because of this thread. Very awesome, and I expect to be doing some business with Mr. Wells.

I have a .357 50th Anniversary flat top incoming, and searched the web for "aluminum bisley grip frame" to get here. Started off thinking about the weight, but at 6'4", my long, skinny fingers put a knuckle almost against the trigger guard on a factory Bisley frame. The options RW is offering are most excellent.

I saw some comments earlier in the thread about weight reduction of aluminum vs. brass vs. steel, but very limited quantitatively. Has anyone put raw or finished grip frames on scales, or done a "before and after" on finished guns? Just wondering what packin' weight I might be able to get the flat top with the undersized peashooter holes through it down to.

I'd be surprised if the CAD software used to design these things can't very easily report a volume for the machined part, or even a weight if the density of the metal was entered. That would be a neat piece of information to have added to the web site.

|

|

|

|

Post by RDW on Sept 29, 2020 13:41:14 GMT -5

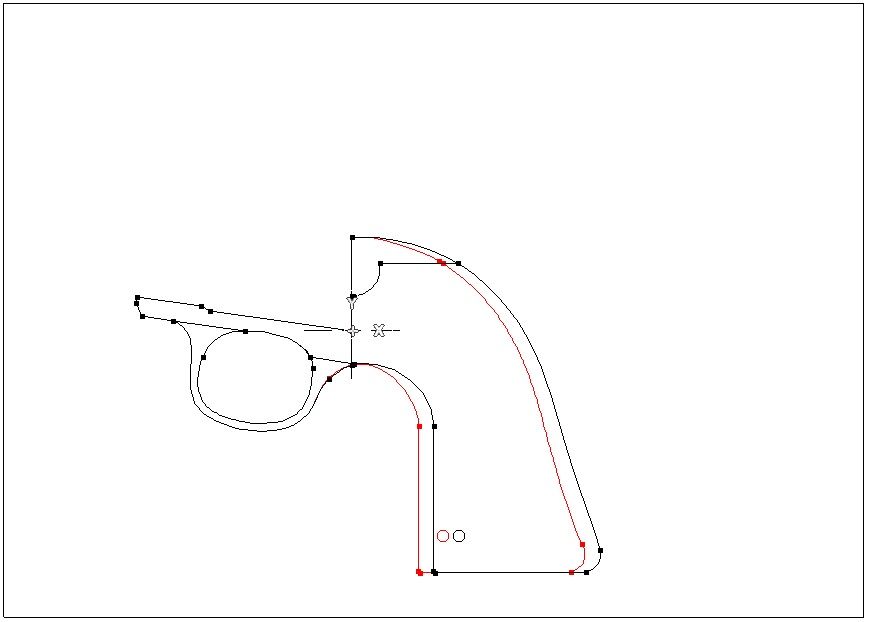

Greetings, all! I'm not big on the "Hello World" thread, so here's my "Hello World" post to this forum. I have checked out some info on this site before, but joined up because of this thread. Very awesome, and I expect to be doing some business with Mr. Wells. I have a .357 50th Anniversary flat top incoming, and searched the web for "aluminum bisley grip frame" to get here. Started off thinking about the weight, but at 6'4", my long, skinny fingers put a knuckle almost against the trigger guard on a factory Bisley frame. The options RW is offering are most excellent. I saw some comments earlier in the thread about weight reduction of aluminum vs. brass vs. steel, but very limited quantitatively. Has anyone put raw or finished grip frames on scales, or done a "before and after" on finished guns? Just wondering what packin' weight I might be able to get the flat top with the undersized peashooter holes through it down to. I'd be surprised if the CAD software used to design these things can't very easily report a volume for the machined part, or even a weight if the density of the metal was entered. That would be a neat piece of information to have added to the web site. Greetings to you sir and welcome! On average steel Bisleys weigh between 9.8 to 10 ounces, Brass an ounce and a half more , mainly because there is a little extra meat there for your whittling pleasure. I have to leave some extra on the sides and the top so you can match it perfectly to your frame. By now you have probably noticed that the ruger mainframes are not all the same. Aluminum Bisley frames are less than four ounces! I have a few that have come in at about 3.5 Oz once they have been fit. I myself am a little on the large side. which is what prompted me to make my own grip frames 35 years ago. My fingers are not exceptionally long but are more like a sausage and my palms are a time and a half the length of my fingers. So need less to say the xr3 frames wont work for me. As far as a conventional plow handle goes i prefer my Super Blackhawk with Bisley trigger Guard plus .300 in length. The bisley trigger guard option moves the trigger guard forward an eighth of an inch allowing for more knuckle room. For really large hands we have developed in kahootz ( hope i spelled that right, Haha) with David the Awsome Stud Bradshaw, A new frame dubbed the Bradshaw which has been extended rearward or lengthened 3/16 of an inch giving major knuckle room for larger hands. The 4 degree forward bisleys are rotated forward to allow a much more pleasant angle of approach to length of trigger pull and are rolling over the knuckle during recoil instead of directly in to it. The Wells number 9 is my version of a keith number five, which was my ninth attempt to make that shape to fit my sammich grabbers. I have over 200 different combinations available at this moment and experiments with very experienced members of this forum testing weekly. You will find a wealth of single action Knowledge on this forum sir and a major inspiration to our development here at RW GripFrames! We have found the weight to be negligible for large men and sometimes, relieving to much weight on one end tends to take the balance that you are used to out of wack! With longer barrels the heavier brass adds balance. It all boils down to preference. And we will make the dam thing out of unobtainium for you if you so desire. LOL Stainless and and steel are coming soon. I built a 50 special for my self that is on one of the previous pages just in case a bear stuck his head in my tent and needed to be sent to the happy hunting ground. It comes in at 2 pounds and six ounces but it has 5 very large holes in the cylinder and a short barrel you can stick a broom stick in! It sports a standard bisley in aluminum. The following overlay will demonstrate the difference between the Bisley And the Bradshaw Bizzard. Standard bisley in Red and the Bradshaw in Black! Notice the knuckle room. As far as the software is concerned , yes it will do wonderful things but i am a hands on guy. All of these have been designed by hand and then transfered to the software for the G code programming side. Trial and error produces better results for me, and i have lots of friends with a great variation in hand size for testing. Alot of them are on this forum. One in particular is a monster sized man Named Todd, who is just about the most super guy you could ever meet. He will grab a Ruger maximum and you would swear he is holding a single six. His hand wraps around a sixgun like most people would grab Cheese stick. Hahaha. His wife Kayla is A seasoned six gunner herself and a real sweet heart. Let there be no mistake, this woman handles the 475 linebaugh like a champ and we developed the Kaytod Bisley for her shorter fingers. The back strap is moved forward and tilted forward 2.5 degrees and it works well for her handsize. Any question please do call. 832-581-3901 I think we can getcha where you wanna go! Once again welcome Sir.  |

|