Ronnie, I feel like we've talked about this and you made the jig so obviously, but how consistent are the pin locations relative to each other in a Ruger frame?

Haha Exactly!

Ok well thats an easy one buddy!

Very!!!!!! I have taken an average between 7 different OM frames. Now i am sure there is going to be that one, you know the one off, koo koo, out of wack one that i usually end up with. LOL

On the new model, i have a factory dimension print! So i know where they should be.

As with any Ruger though as we have seen, there will be variables.

So where do we start huh? Or do we just give up trying to make improvements? Not My Nature fellas. Weve got to start somewhere.

Im going to keep trying to get down and Boogie! I cant Help it. Just luv to dance with the devil i guess.

But im not sure everyone here has a good idea of just how deep into this i have gone over the years.

It started in the eighties for me with Cylinders. I had to get a handle on the dimensions so i could make my big boomers without fear of blowing myself up.......... Again, Lol.

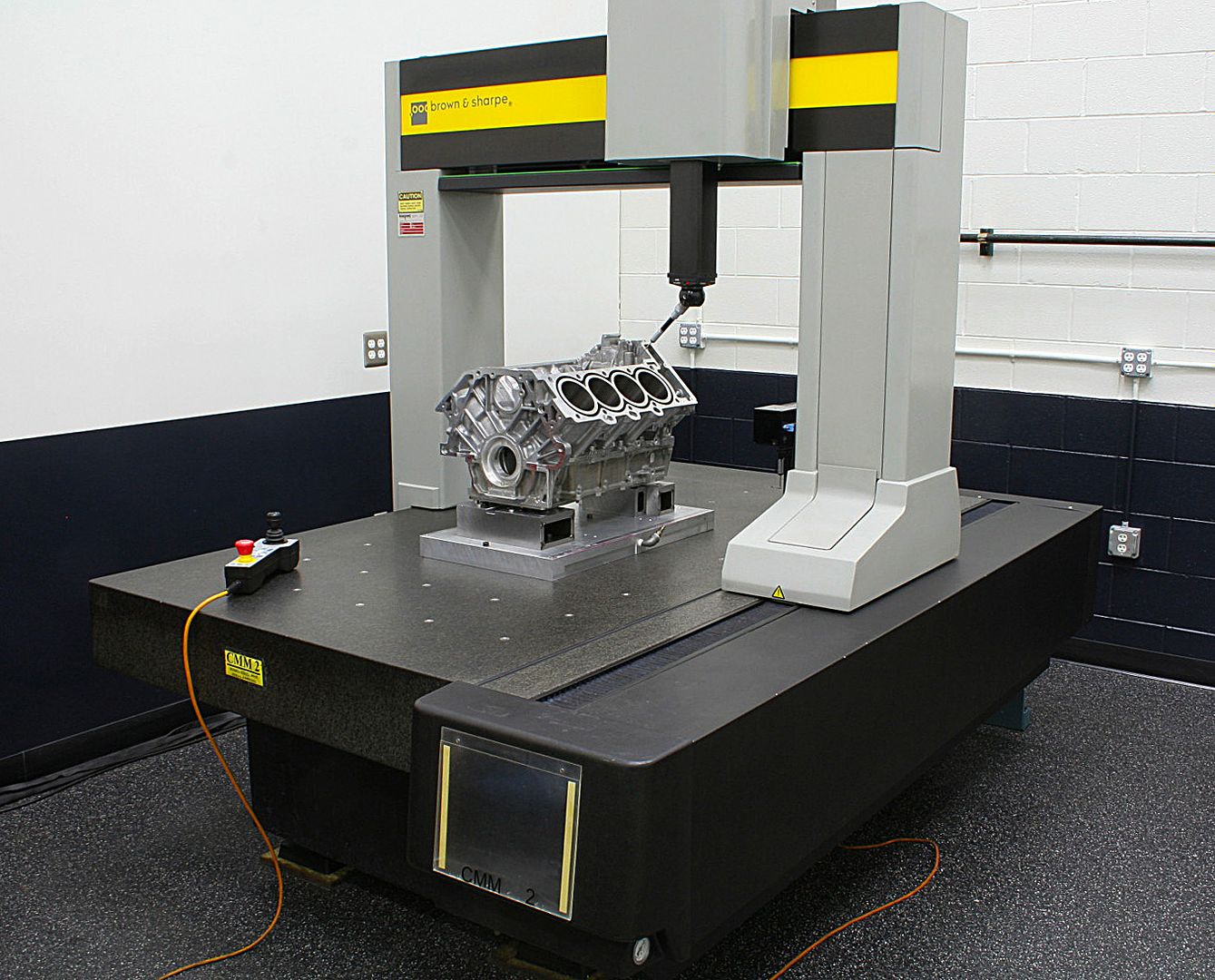

So here is a picture of about a Hundred grand of my retirement worth of Browne and Sharpe CMM Excel with Quadracheck Software we use for engines and Now Gunparts. Haha.

For those of you who are familiar, you know how cool a CMM ( Coordinate Measuring Machine) and useful a tool it can be.

For those of you who do not, It is an Invaluable tool for getting down to the last umpteen nat hair accurate measuring value.

The computer readout gives me the geometry i need to program the part correctly for perfect fit.

And i use the crap out of it. Haha

It uses a touch probe that is so sensitive, the CMM is in a room that is temp controlled so that the part and machine normalize together so there is no growth or distortion of the part dimensions!

The only variance i have found of any significance is the inside of the frame where the trigger rests against! I have a variance in the location of the three holes for Trig,Ham, and Latch to the back

and the bottom of the frame where the Grip Frame mounts, But not each other! And its just a couple of Thousandths.

So that wont make a difference on the Jig as far as test fitting them together before assembling them in to there final resting place in the Gun.

This is something i have always wanted to do! I have an investment in this whole project that would detour most sane people from attempting, But i must doit!

And im just trying to bring something to the table for everyone that might inch them all along to understanding the inner workings of the Ruger SA and also allow them to make some adjustments with

confidence! How many Gunsmiths are out there guys that can do the kind of work you wish you could do yourself and how long does it take for them to get to you for a simple trigger job.

Correct me if im wrong guys but i have seen a lot of posts that tend to lean toward disappointment and frustration.

Its not Rocket Science, Just finesse and understanding. When you can see the trigger and hammer work together through there stroke action, it sheds a whole new light on it!

I dont want to take away anyones (Gunsmiths) lively hood here fellas. JUST ENHANCE YOURS!