|

|

Post by RDW on Jul 7, 2024 11:37:42 GMT -5

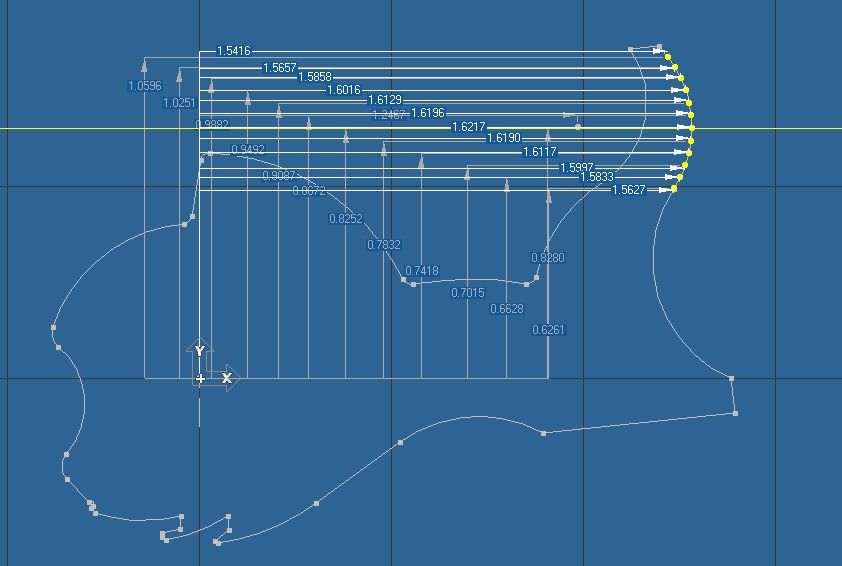

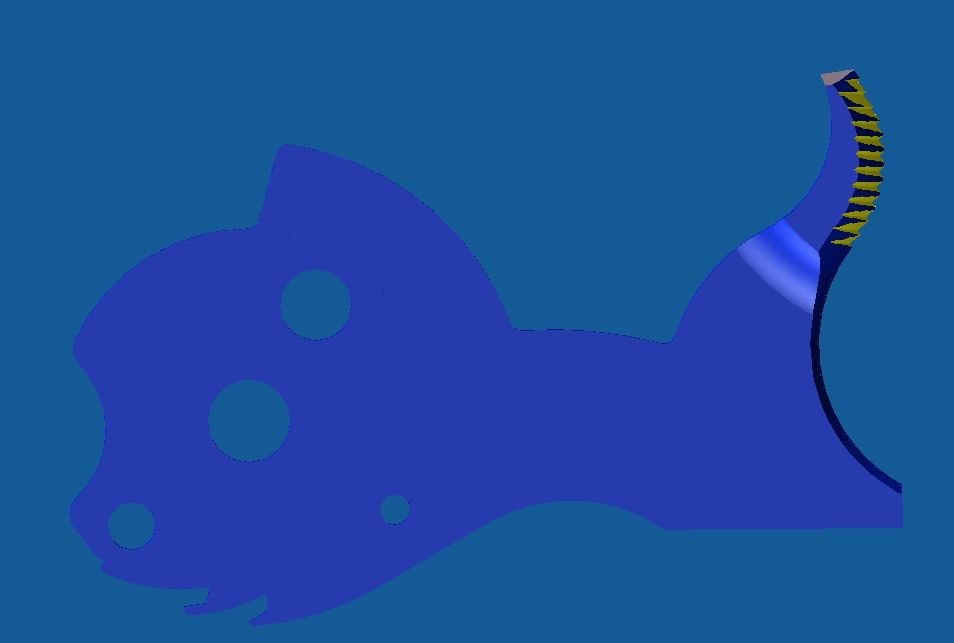

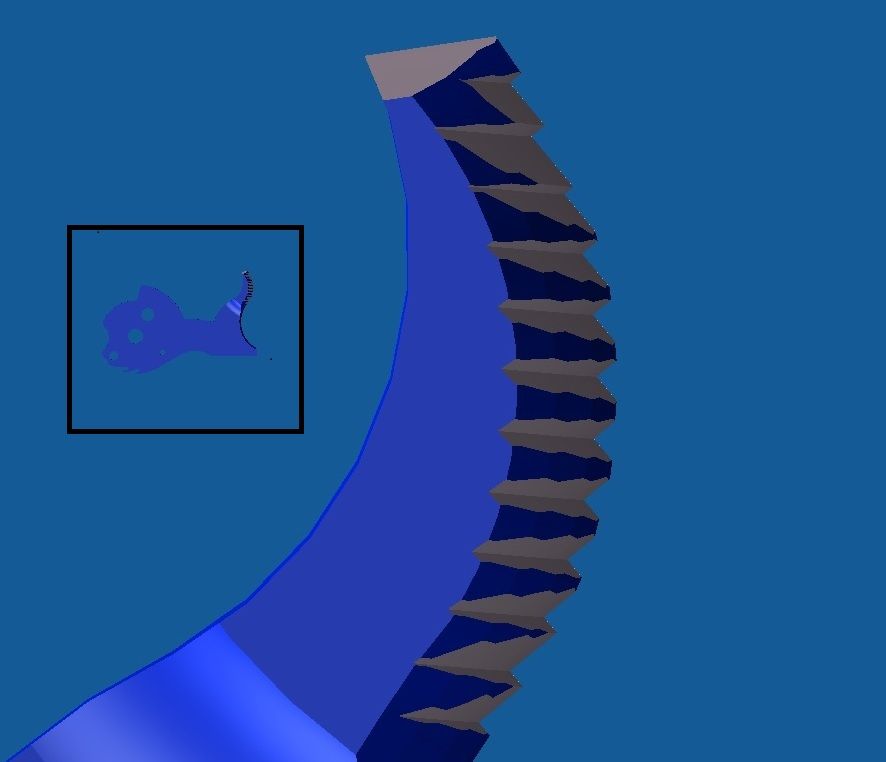

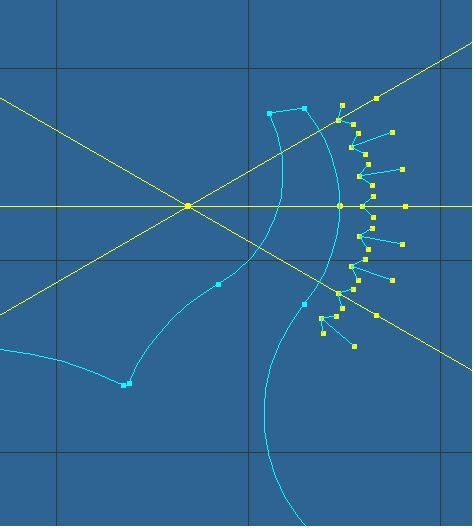

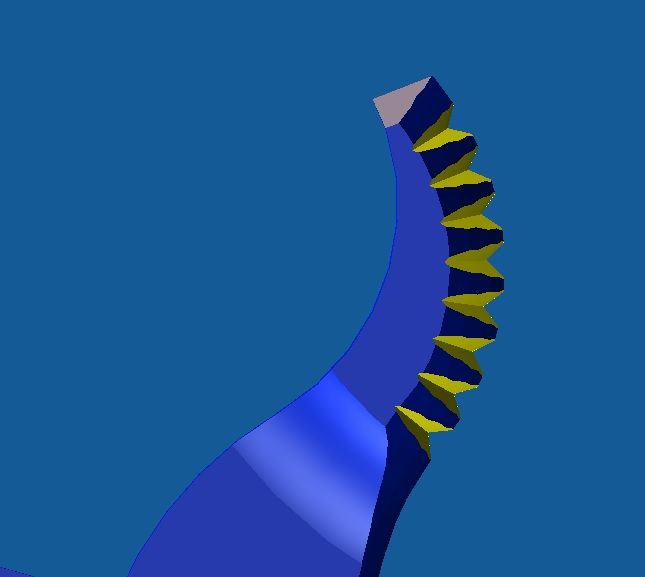

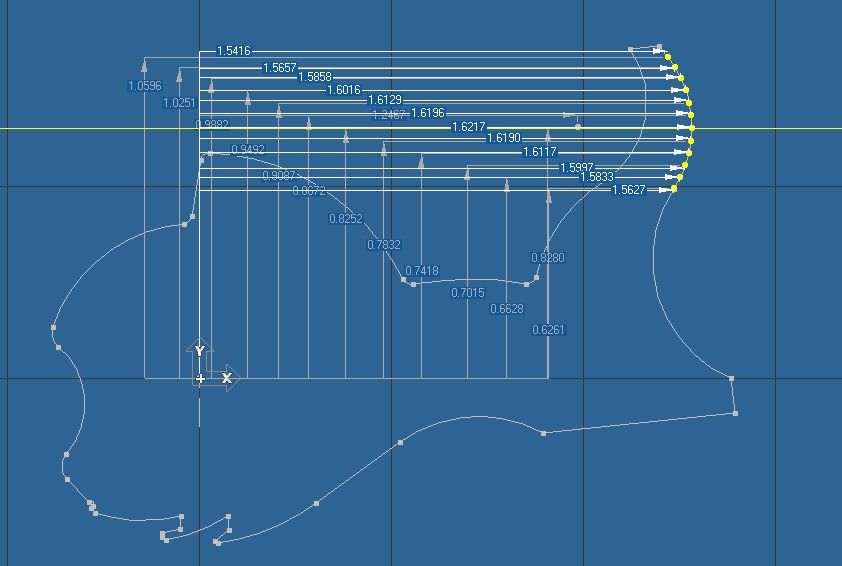

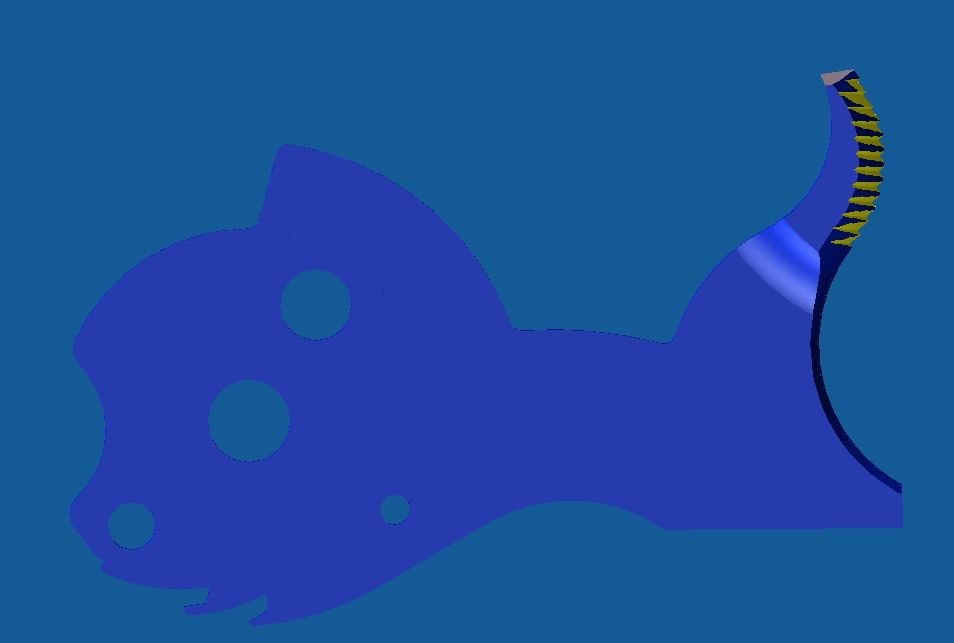

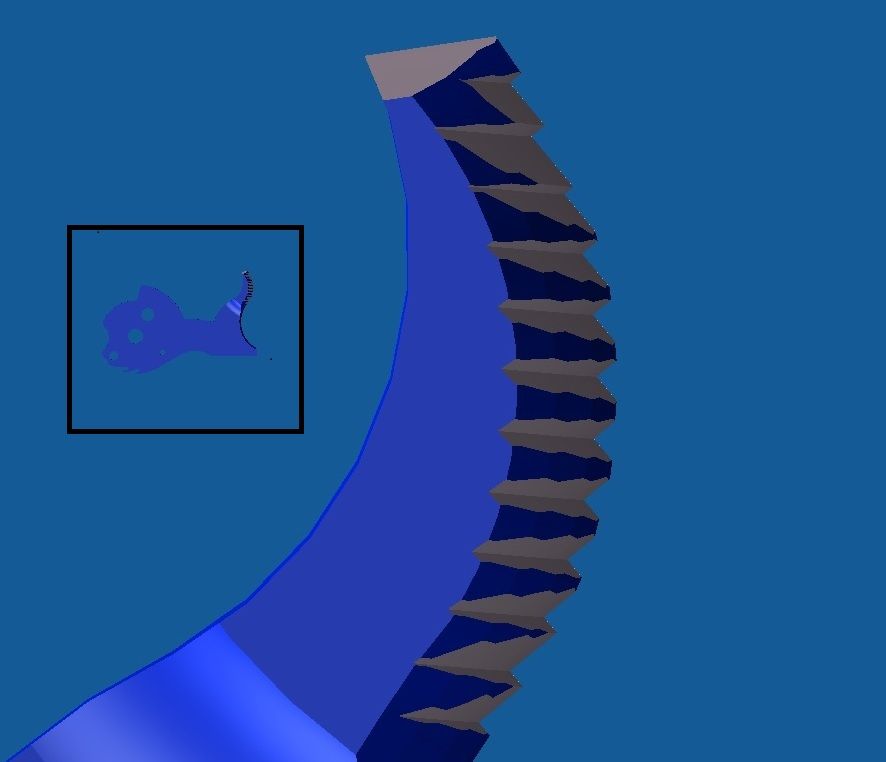

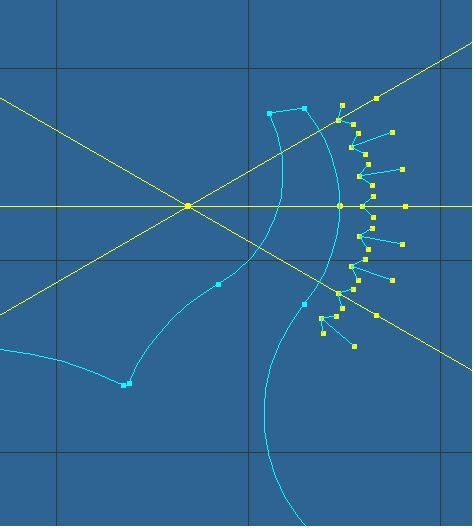

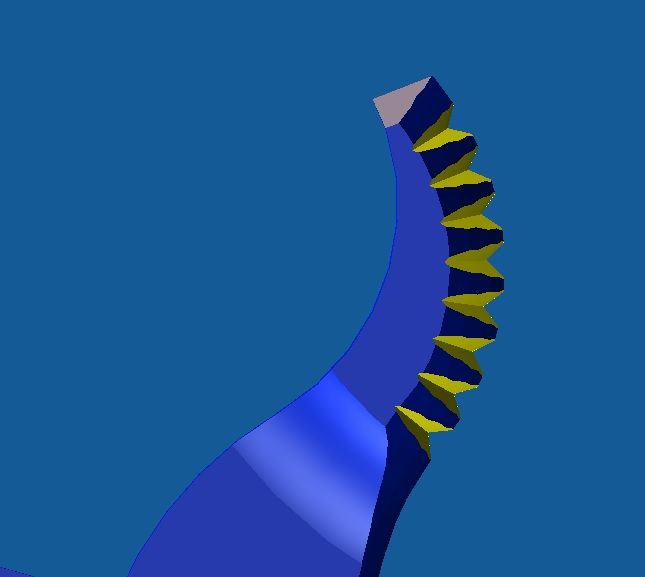

Had a talk with Ronnie and he suggested I look at the pictures he’d just posted of that Lightning gripped 32 Single Six. Admittedly, I was already resolved that the prototype was near perfect in its presentation in previous posts. And if I may, a personal note here; I’m one of those few who fancy a greater appreciation for the SBH Hammer over the Bisley Spurred Hammer. Heresy to some, I’m sure. Then he asked, “What do you think?” Well, me being just a noob regarding the details in appreciating a fine, true custom six-gun, I lamely tried to respond. And in the course of our meandering conversation, I don’t think I properly or coherently expressed to him my opinion. I mean I was already in awe of the graceful dimensional balance he’d achieved in the hammer’s spur. But the fine radial detail of the hammer’s cocking serrations just blew me away. Yea folks, my opinion, it is a work of art. And knowing Ronnie, its more than the epitome of mechanical engineering. He was also apologetic about how long it’s taken to get to the point where he was now able to produce these mini SBH hammers. So, I made sure to tell him that in this endeavor, patience for me, was easy and a good thing. So, I’d also like to throw in a quote I got long ago from who knows where that I think applies……. “One should never attempt to expedite the artist in his labors. For only in his own time and imagination can he ultimately achieve that thing of beauty.” Gunny I Love the simplicity of the Super wide spur. What i dont love is that nowadays the serations are all over the place. They have changed so much thru the years and after serious microscopic comparisons of the SBH Hammers thru out the last couple of years i have come the the conclusion that details have faded in to obscurity. At one time they were perfect. Now it looks like they are casting the serations. After countless hours of going back and forth with David Clements and countless hours of geometry drawing a tuning the programs to make these not only producable but consistently correct in all dimentions. Most of all Detailed to a degree that will make it stand out. And be functional from here on out. What i have found is that the majority of all makers are because of production and cost the serations when machined are coming from one direction, usually at 90 degrees from center. Here is a pic of what i am talking about. The yellow line represents the cut level in the z axis at various heights to make the cut all up and down to form a seration. after close observation i copied that technique and was most displeased because it makes the seration look wonky and inconsistant.  Her is a closeup of what it looks like.  The later face forward and the closer face back. WONKY, Dont like it.  So after a buttload of experimentation here is how i do it now. This is showing just 3 of the rotating axis positions and how i acheived the look and feel i have been after. You will notice that the rotating axis cahnges position 10 degrees 8 times for 8 serations. Not only that but also the Z axis height and the Y axis position as well. Notice the yellow dot left of the seration cut. That is the center of the outer cut surface.I am now cutting each seration to the invisable center so that it follows the round contour perfectly.  Each cut is following the arrow to the center at the same distance.  As u can see the differance is phenominal. The serations are not only even but all following the contour of the spur.  Hope that gives some perspective on the amount of work that has gone into these. Bluing some now. Lets see how they turn out huh? R |

|

|

|

Post by RDW on Jul 7, 2024 12:08:19 GMT -5

Yep, Looks dandy all blued up.   |

|

|

|

Post by RDW on Jul 7, 2024 12:12:05 GMT -5

I think that is really the perfect hammer. It just fits everything perfect. I like it following the contour of the grip frame ears and where the spur flows in the arc of travel. It never looks to be in the way but is always right there easy to find. I liked the lines following the recoil shield of the previous version also I dig the sculpted look it has. Kind of an art deco look and feel of the 20s and 30s. Thankyou coltguy. It took a few trys to get that booger to follow an averaged S6 Recoil sheild. I think they just look subconsciosly better when they flow into the frame.  The Bushing or bearing surface protrudes a bit on this one mainly because the lightning grip frame finishes a lot lower at the ears but i can remedy that. R |

|

fm027

.30 Stingray

Posts: 101

|

Post by fm027 on Jul 13, 2024 11:32:35 GMT -5

Are those blued hammers ready for taking orders on and shipping Ronnie? I want one of those for my trapline SS, that's a damn nice hammer.

Are they being done as a half-cock style??

|

|

|

|

Post by RDW on Jul 17, 2024 14:21:58 GMT -5

Are those blued hammers ready for taking orders on and shipping Ronnie? I want one of those for my trapline SS, that's a damn nice hammer. Are they being done as a half-cock style?? Available Shortly. Glad you asked about the Half cock. I personally cannot understand why anyone would want or what the appeal is for a half cock on a new model. The need for the half cock knotch to load the revolver was eliminated by the brilliant design of Bill Rugers new model lock work and transfer bar system. So with that being said i, the reason i made the statement about understanding, please elaborate on the need or the desire. I am all ears. On the old model it is done in such a fasion so that it wont interfere with the trigger when lightly pulled. The trigger sear surface is very small. The shape of the new model hammer doesnt lend it self as well and you have to do a lot of reshaping of the trigger so that everything clears. Is it a cool factor thing or is there a particular shooting style that requires it. I am limited on the various techniques and clubs. Shot some silloette but mainly just shoot long range and hunted for the last 50 or so years so i am missing something here. It can certainly be done like Power Customs but i havent done any like that yet. If it makes some sense, i will certainly entertaine the idea. R |

|

fm027

.30 Stingray

Posts: 101

|

Post by fm027 on Jul 17, 2024 20:35:46 GMT -5

Are those blued hammers ready for taking orders on and shipping Ronnie? I want one of those for my trapline SS, that's a damn nice hammer. Are they being done as a half-cock style?? Available Shortly. Glad you asked about the Half cock. I personally cannot understand why anyone would want or what the appeal is for a half cock on a new model. The need for the half cock knotch to load the revolver was eliminated by the brilliant design of Bill Rugers new model lock work and transfer bar system. So with that being said i, the reason i made the statement about understanding, please elaborate on the need or the desire. I am all ears. On the old model it is done in such a fasion so that it wont interfere with the trigger when lightly pulled. The trigger sear surface is very small. The shape of the new model hammer doesnt lend it self as well and you have to do a lot of reshaping of the trigger so that everything clears. Is it a cool factor thing or is there a particular shooting style that requires it. I am limited on the various techniques and clubs. Shot some silloette but mainly just shoot long range and hunted for the last 50 or so years so i am missing something here. It can certainly be done like Power Customs but i havent done any like that yet. If it makes some sense, i will certainly entertaine the idea. R The feature would line up the cylinder-chambers square inside the loading gate at half cock Ronnie, making loading and unloading simpler and quicker by not having to manipulate the cylinder with your opposite hand to manually hold the chambers in-line with the gate space for each shell. Only a half cock hammer or a free spin pawl mod can do that to a new model... I prefer the half cock method on my guns. That's why I asked. I will absolutely be putting an order in for my gun when they're ready, I think this new hammer is terrific. Half cock would put it over the top for that ease of loading & unloading, as explained. Frozen fingers during dead of winter on the trapline especially, that feature would really be great to have. |

|

|

|

Post by RDW on Jul 18, 2024 9:16:06 GMT -5

Available Shortly. Glad you asked about the Half cock. I personally cannot understand why anyone would want or what the appeal is for a half cock on a new model. The need for the half cock knotch to load the revolver was eliminated by the brilliant design of Bill Rugers new model lock work and transfer bar system. So with that being said i, the reason i made the statement about understanding, please elaborate on the need or the desire. I am all ears. On the old model it is done in such a fasion so that it wont interfere with the trigger when lightly pulled. The trigger sear surface is very small. The shape of the new model hammer doesnt lend it self as well and you have to do a lot of reshaping of the trigger so that everything clears. Is it a cool factor thing or is there a particular shooting style that requires it. I am limited on the various techniques and clubs. Shot some silloette but mainly just shoot long range and hunted for the last 50 or so years so i am missing something here. It can certainly be done like Power Customs but i havent done any like that yet. If it makes some sense, i will certainly entertaine the idea. R The feature would line up the cylinder-chambers square inside the loading gate at half cock Ronnie, making loading and unloading simpler and quicker by not having to manipulate the cylinder with your opposite hand to manually hold the chambers in-line with the gate space for each shell. Only a half cock hammer or a free spin pawl mod can do that to a new model... I prefer the half cock method on my guns. That's why I asked. I will absolutely be putting an order in for my gun when they're ready, I think this new hammer is terrific. Half cock would put it over the top for that ease of loading & unloading, as explained. Frozen fingers during dead of winter on the trapline especially, that feature would really be great to have. I gotcha. Makes perfect sense. Just far enough to hold the pawl arm in a different location so you can line up the holes like the old model huh?. Perfect , Thankyou. The current provider of the free spin concept is not the first to doit. Myself and several other men i have known over the last 4 decades have been doing something similar for years so i never needed to have that option. 5 shooters done the way me and everyone else has, negates the need for a free spin pawl because the top of the pawl arm is low enough to clear the ratchet. But on a six shooter it makes good sense now. Thankyou sir. I always mod my stuff. Cant seem to leave anything alone. Hahaha. I will look into it as this project proceeds. Pretty much back to a normal pace today. After cleaning up the aftermath of 5 hours of hundred mile an hour wind and rain from our new freind Hurricane Beryl Last week and 8 days of no power made my schedule even more stretched backward than it already was. LOL. R |

|