I think it's hit or miss with hammers and triggers. But more miss than hits.

Absolutely spot on Kevshell. More miss than hit.

This round of managment has no desire to cater to the regular ole joe. And that has come straight from the horses mouth.

All of what i and others have been able to lay there hands on from say, Midway or brownells are definately blims.

I Love Ruger, but i am tired of working on a part for hours to get it to some measure of usability much less perfection.

They will never produce any more blued steel hammers because the stainless will work for both. That is there stance.

The problem here is , BILL and Junior are gone now and nobody gives an obese rodents behind about single actions at the top now.

So To hell with it. i am making my own. I have the old models down. so now its the New models turn and i am right smack dab in the middle of it.

Today is the finall steps and machining of the new model single six conventional work holding.

These are not cast crap that are dimentionally all over the place. They will be spot on and made to work on any new model.

However like my good freind and mentor David Clements, I AM ANAL!!!!!!!!!!! OCD or what ever you want to call it.

I have to make them producable as well and that takes time. Several things that i wanted to improve is consistancy though.

I have noticed so many times that when you look at the back of the grip frame ears surounding the back of the hammer, the hammer is down or inset and that drives me crazy.

See the area pointed out with a red arrow that i am talking about.. I know that seems silly but i want that even. It just looks better and its a WHILE IM AT IT kindof thing.

So here are a couple of new model blanks before machining to give you an example.

Ruger on the right notice the extra .075 thousandths on the back of mine. That seemed to be the average so far.

By the way these are the Super Blackhawk Mini spured Single 6 blanks with a .490 wide spur just like its big brother.

They are cleared out on the sides .006 thou just like the old model so that the bluing or what me and Bobby and Dusty figured out how to do this week in Friona. ( Case colored)

Bobby has a fantastic handle on his procees but we experimented with temperatures for this Material and got a winner. These are Heat treated then tempered to perfection and then case colored a little differenty so that they would retain a 100 percent of there hardness. I am very pleased. And they are beautiful. AND they will last.

Even my Old Armys are cleared out.

These new models are a priority because of a dozen 500 Linebaugh builds and another dozen 38 special single sixes that are complete less a super ninja ultra Boogie down hammer.

Get them done and they are out the door.

Then, hahahahaha, oh ya. you know. BUT WAIT, THERES MORE. lol

And this might not be the place and please forgive if this is considered a high jack. but i am very happy to report that my drawings and programs are done for another crazy idea you guys came up with, GOD Bless you.

Yes sir ee.

REDHAWK HAMMERS.

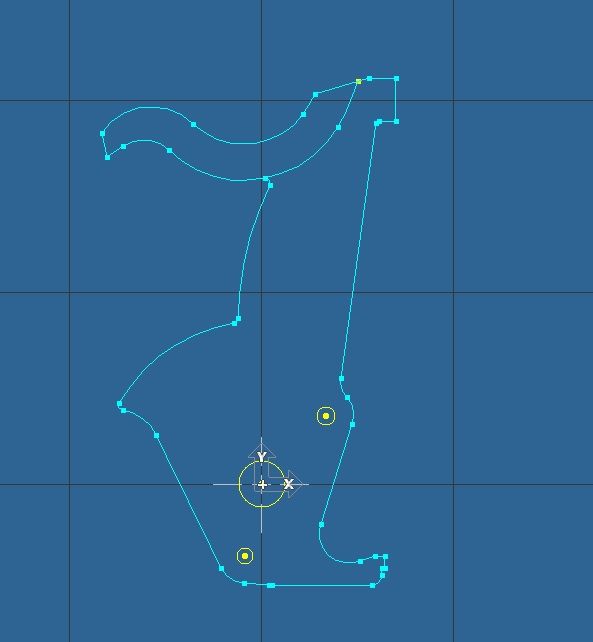

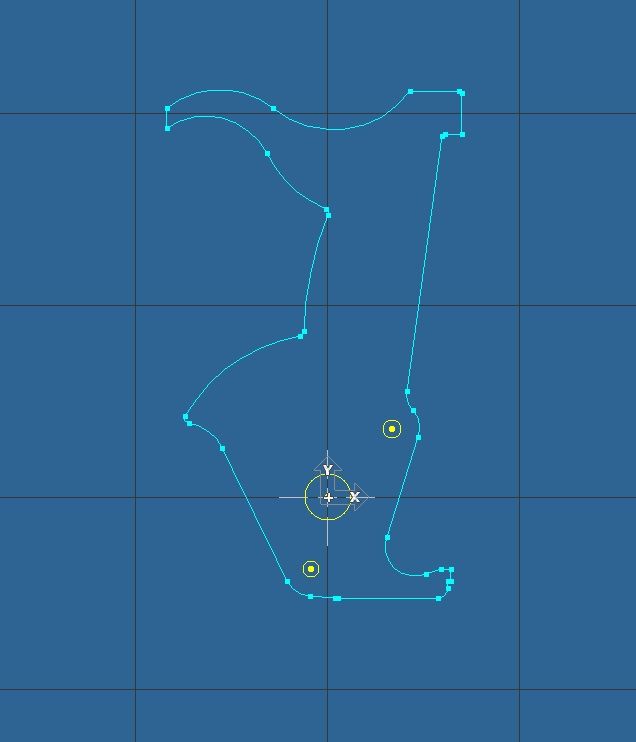

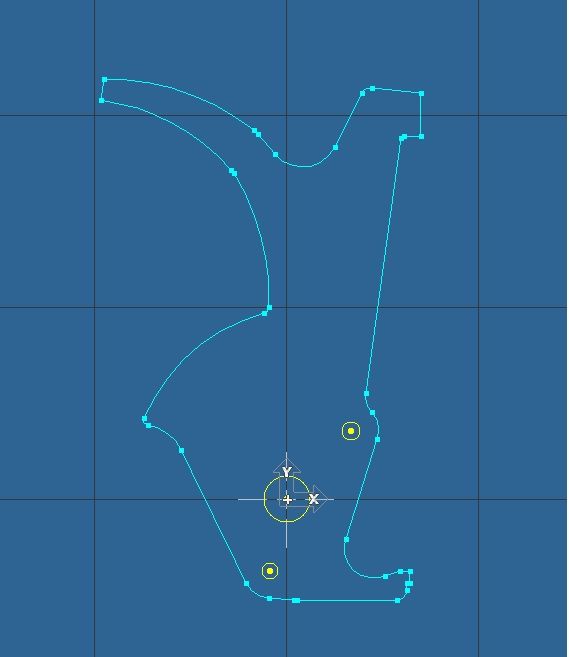

Here is a preview.

RedHawk Bisley Spur.

REDHAWK SUPER Blackhawk wide spur.

AND REDHAWK Smith And Wesson N frame spur.

I really like this one. Cant wait to test it.And or perfect it.

Well im off to the shop to cut these 2 blanks out and some more 38 smith barrels for single sixes.

Hope i didnt high jack yall, just wanted to show you some of the madness coming out of the RW Shop.

And to say hang in there i will have new model stuff soon.

R