Post by lar4570 on Jan 27, 2024 19:56:13 GMT -5

Hi everybody. Back in December I was sitting in my deer stand and thought, I need a new gun to hunt Hogs with. I already have ARs in 223, 7.62x39 and 450 Bushmaster, so I thought maybe a medium bore something.

The 358 Win is a great round in the AR10, but most AR10s weigh about 10#. The 358Win is just too long to fit in the AR15. So I wondered, could I just get a 358 barrel and run a stock 358Win reamer in partway to cut the chamber. Then take stock 358Win dies and cut the bottoms off just a little to use for loading dies. That would cut a great deal of cost out of the project by not have to get cu$tom dies and a cu$tom reamer ground.

I searched around and found Deadshot Barrels in Oregon. They make 358Win AR10 barrels and said they would turn one down to AR15 size and cut the chamber if I could send them a formed case and bolt to set the headspace with.

I pulled up Midway on my phone and started ordering Stuff. When I got home a week later, the stuff was waiting for me. I thought I would limit the cartridge to 180 and 200 grain bullets, so I ordered some Hornady 200FTX and 200 Interlock SP, also some Speer 180s. I measured the nose length, got my max magazine length of 2.300", did a little math and came up with a max case length of 1.660".

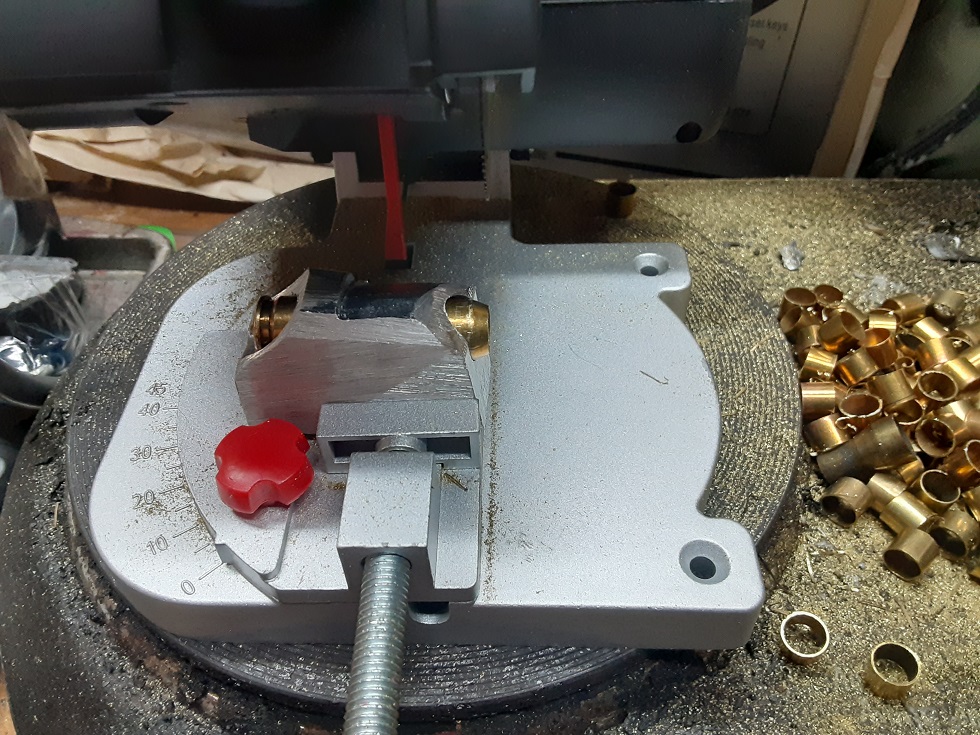

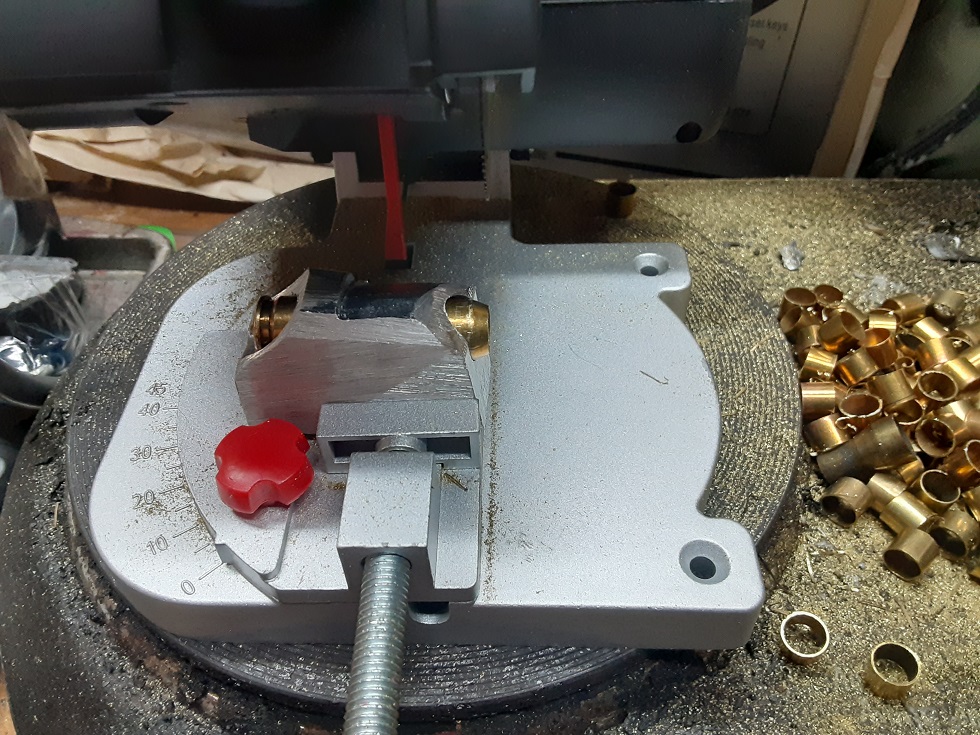

The little 2" Harbor Freight mini chop saw works great for cutting cases down.

I made a little jig to hold the cases in place. It's a straight rip off of the Squirrel Daddy 300BO jig. It's just scaled up for a 308win case.

I used a cut off wheel on the grinder to shorten the size and seater dies.

I cut off some 308 cases, lubed them up and stuffed them into the shortened dies.

Everything went smoothly, so I turned the necks to .015"

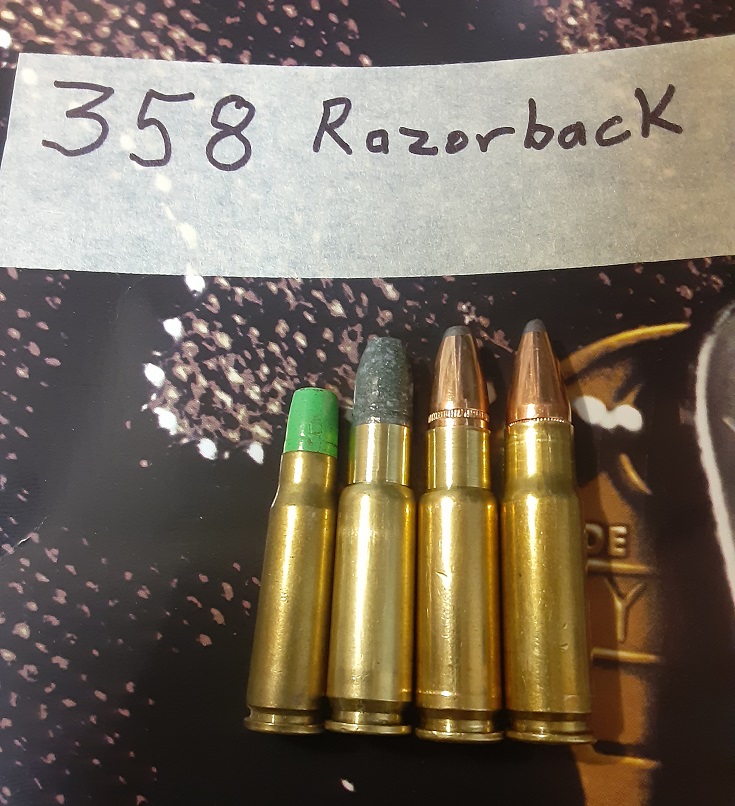

Then loaded some dummy rounds to look at. At some point I'll try cast bullets in it, so I put in the Lee 200 and my own Fat35 which comes in at 265gn.

I shipped a couple of the cases and the 450 Bushmaster bolt off to Deadshot and started waiting.

Palmetto state Armory had the BoarHunter-15 lower in stock, so I had to order one.

The Lower came in, so I put it all together.

After a short 3 week wait, the barrel showed up.

I put the rest of the pieces together and cobbled this together.

The dummy cartridges fed perfectly out of 6.8SPC mags.

It had a few hickups on the bolt closing fully a few times. It turned out the extractor was very stiff and not snapping over the rims all the time. A little oil and manipulating a few times and everything was good.

I loaded some test rounds(200FTX with RL7) and started a function test. I got an adjustable gas block because who knows what kind of port pressure and gas volume I'd need to cycle the gun without being over gassed and batter everything...

With the gas block all the way open the test rounds would eject, but not lock the bolt back.

I measured the gas port at .086" and opened it up to .096".

With the gas block all the way open, it would lock the bolt back on the last round.

With the gas block closed 1 position, it would eject, but not lock the bolt back. So it looks like I guessed about right.

Now it's on to load development and see if this thing will shoot acceptably.

The 358 Win is a great round in the AR10, but most AR10s weigh about 10#. The 358Win is just too long to fit in the AR15. So I wondered, could I just get a 358 barrel and run a stock 358Win reamer in partway to cut the chamber. Then take stock 358Win dies and cut the bottoms off just a little to use for loading dies. That would cut a great deal of cost out of the project by not have to get cu$tom dies and a cu$tom reamer ground.

I searched around and found Deadshot Barrels in Oregon. They make 358Win AR10 barrels and said they would turn one down to AR15 size and cut the chamber if I could send them a formed case and bolt to set the headspace with.

I pulled up Midway on my phone and started ordering Stuff. When I got home a week later, the stuff was waiting for me. I thought I would limit the cartridge to 180 and 200 grain bullets, so I ordered some Hornady 200FTX and 200 Interlock SP, also some Speer 180s. I measured the nose length, got my max magazine length of 2.300", did a little math and came up with a max case length of 1.660".

The little 2" Harbor Freight mini chop saw works great for cutting cases down.

I made a little jig to hold the cases in place. It's a straight rip off of the Squirrel Daddy 300BO jig. It's just scaled up for a 308win case.

I used a cut off wheel on the grinder to shorten the size and seater dies.

I cut off some 308 cases, lubed them up and stuffed them into the shortened dies.

Everything went smoothly, so I turned the necks to .015"

Then loaded some dummy rounds to look at. At some point I'll try cast bullets in it, so I put in the Lee 200 and my own Fat35 which comes in at 265gn.

I shipped a couple of the cases and the 450 Bushmaster bolt off to Deadshot and started waiting.

Palmetto state Armory had the BoarHunter-15 lower in stock, so I had to order one.

The Lower came in, so I put it all together.

After a short 3 week wait, the barrel showed up.

I put the rest of the pieces together and cobbled this together.

The dummy cartridges fed perfectly out of 6.8SPC mags.

It had a few hickups on the bolt closing fully a few times. It turned out the extractor was very stiff and not snapping over the rims all the time. A little oil and manipulating a few times and everything was good.

I loaded some test rounds(200FTX with RL7) and started a function test. I got an adjustable gas block because who knows what kind of port pressure and gas volume I'd need to cycle the gun without being over gassed and batter everything...

With the gas block all the way open the test rounds would eject, but not lock the bolt back.

I measured the gas port at .086" and opened it up to .096".

With the gas block all the way open, it would lock the bolt back on the last round.

With the gas block closed 1 position, it would eject, but not lock the bolt back. So it looks like I guessed about right.

Now it's on to load development and see if this thing will shoot acceptably.

Did you keep the same shoulder angle as a 358/308win.

Did you keep the same shoulder angle as a 358/308win.