Post by RDW on Aug 2, 2023 18:34:14 GMT -5

Ok Gentlemen. After a few years of mealin around on design concept and how to manufacture it. We have them tested, bugged out and ready to ship.

A few of you on this forum have them and we really appreciate how much yall helped with the testing phase of this product. I and Fermin Salute you.

Back story: About the time we were opening up the grip frames for purchase Fermin aproached me with a concept for a rear sight and it was a doozy. The problem was it was machine intensive and very hard to do.

I started the Hammer and trigger project and put it on the back burner.

But we tickled it here and there, but didnt totally dedicate because of all the other products we have been working on. However with all of the deaths and retirements that have plagued our industry for the last year i decided it was time to finish what we started 4 years ago. Mainly because the addition of the New equipment such as the Wire EDM changed the whole way we were thinking about manufacturing. This is a very tiny part and very precision. The edm was purchased mainly for the Hammers and triggers. However i have stacks and stacks of the hammers done and waiting their turn on the mills and heat treat which are rolling as we write, i had a void on the EDM so we put her back to work.

This is what we came up with. I love my old Millet and bomars as well as my Rough countrys and the thought of not being able to acquire them has instigated a new hole in the market, so we are going to fill it.

This part replaces the original blade and allows you to retain the click adjustments that i have always enjoyed about the Ruger site. It as Fermin describes is a Glare eliminator.

Here are some pictures to explain how it works. By tHe way it works fabulously. Fermin really Knocked it out of the park with this one i do beleive.

Big Hairy 500L with a number 6 on it.

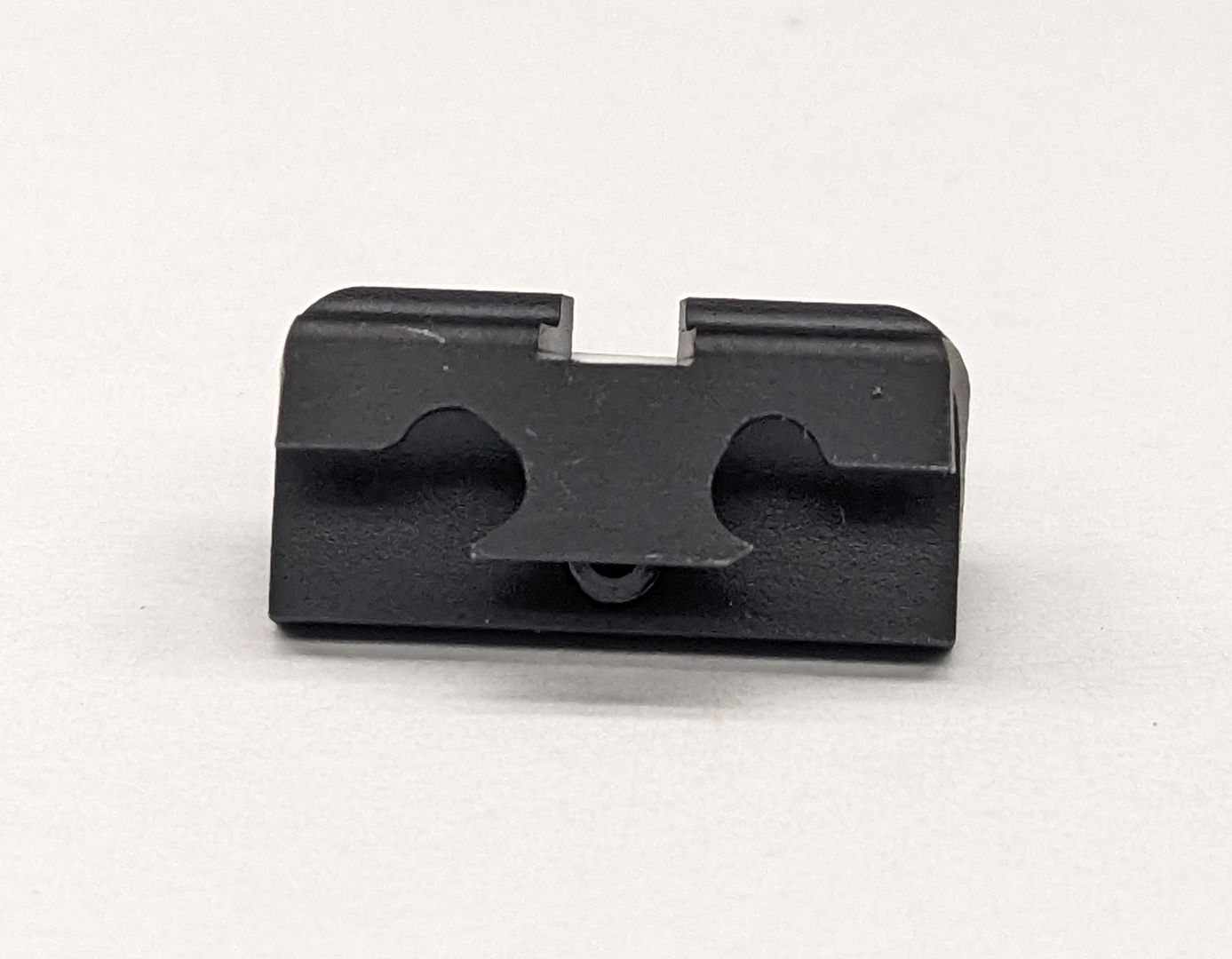

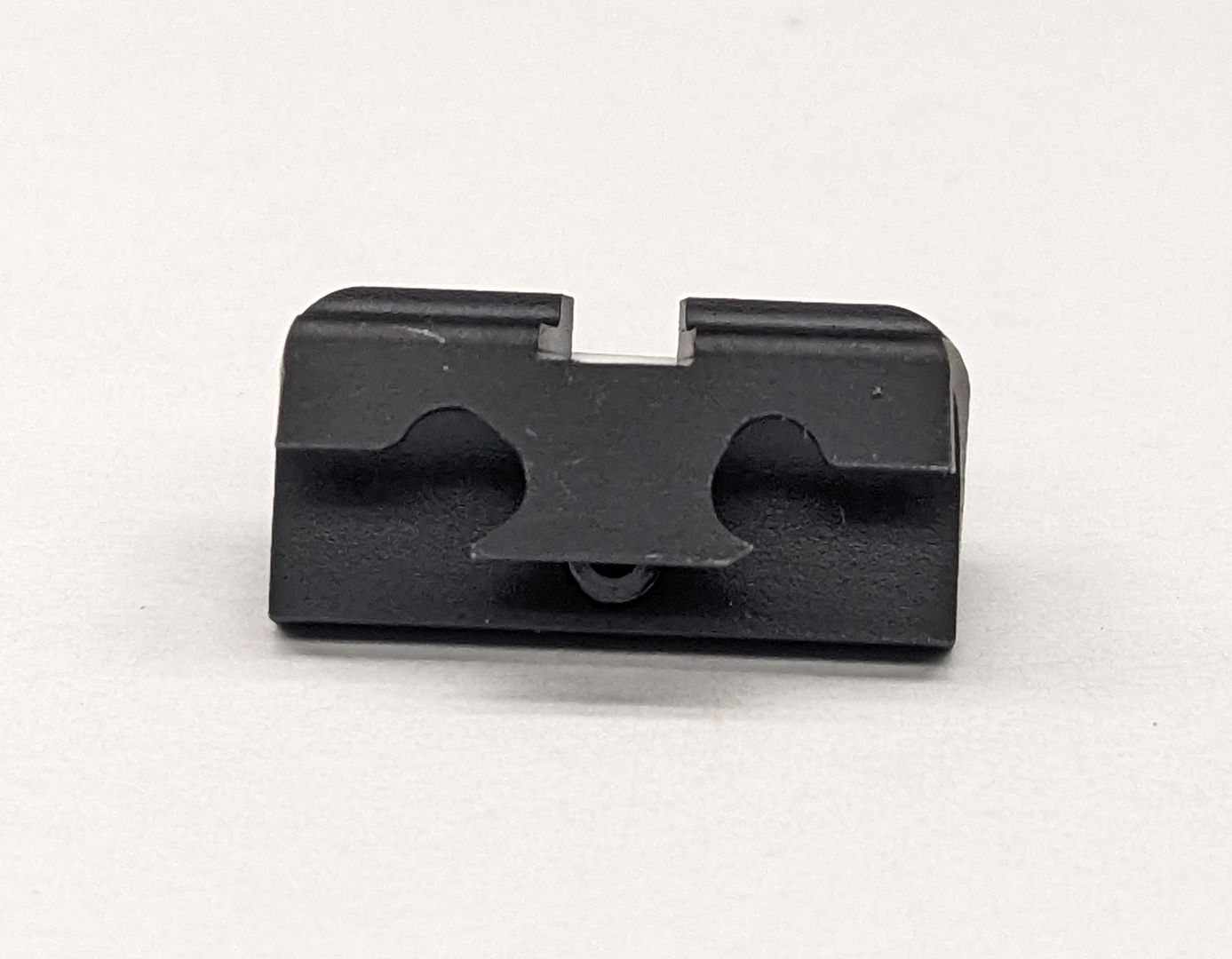

Here is a close up of the rear Face

Here is the mounting Mechanism.

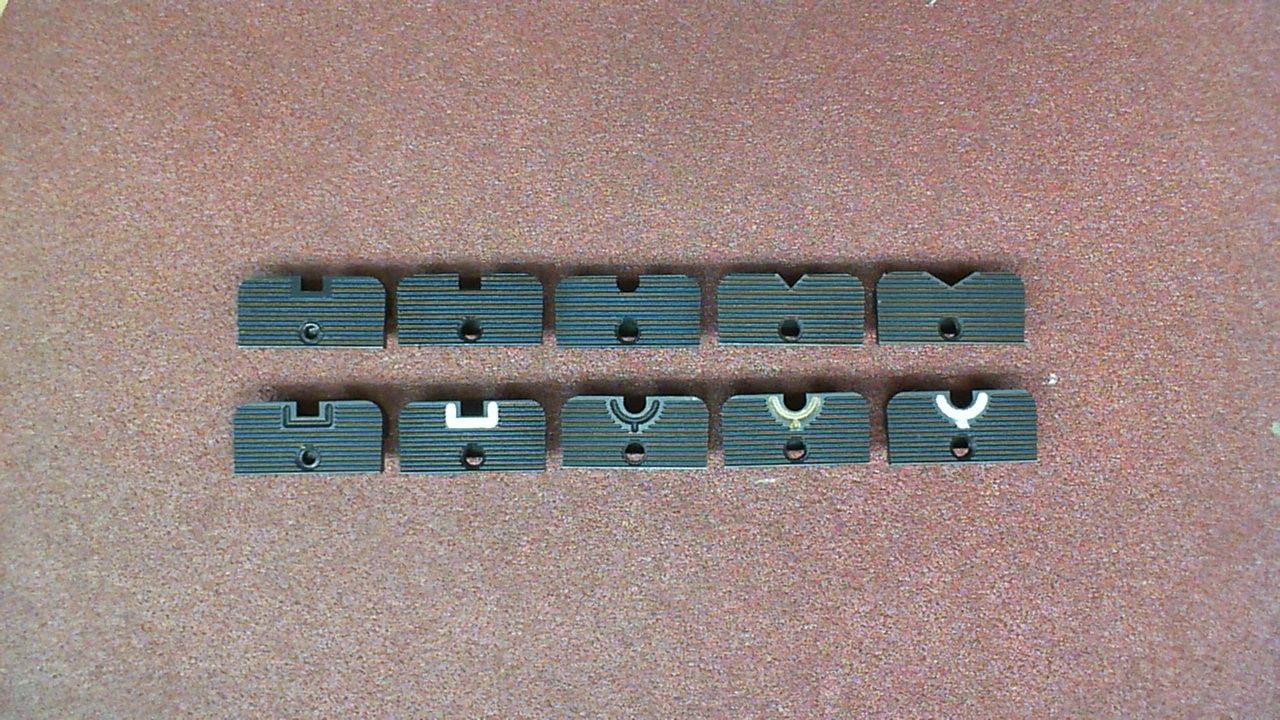

Here is the trough at the top. Notice how they are funneled and angled forward to collect light to from the outline of the front site.

We have them in all neccesary heights.

.390 is the standard. they extend or retract the height in .025 increments. .390 std .415 and .440 tall. there is a low profile for those of you with short front sites as well. .365 and super low profile. 340. I make them in various widths to accomodate the length of barrel. a .120 slot is perfect out to 5 1/2 length for aperfect site picture. However i suggest .110 for 6 1/2 and .100 for 7 1/2 to 10 depending on your preferance. However for you guys that like the 10 1/2 ers like i do such as the super blackie in 44 and 357 Max , The .340 Tall and .090 wide is absolutely Bitchin!

These work well with the single six and all of the redhawks and GPs.

There is so much more to talk about.

A few of you on this forum have them and we really appreciate how much yall helped with the testing phase of this product. I and Fermin Salute you.

Back story: About the time we were opening up the grip frames for purchase Fermin aproached me with a concept for a rear sight and it was a doozy. The problem was it was machine intensive and very hard to do.

I started the Hammer and trigger project and put it on the back burner.

But we tickled it here and there, but didnt totally dedicate because of all the other products we have been working on. However with all of the deaths and retirements that have plagued our industry for the last year i decided it was time to finish what we started 4 years ago. Mainly because the addition of the New equipment such as the Wire EDM changed the whole way we were thinking about manufacturing. This is a very tiny part and very precision. The edm was purchased mainly for the Hammers and triggers. However i have stacks and stacks of the hammers done and waiting their turn on the mills and heat treat which are rolling as we write, i had a void on the EDM so we put her back to work.

This is what we came up with. I love my old Millet and bomars as well as my Rough countrys and the thought of not being able to acquire them has instigated a new hole in the market, so we are going to fill it.

This part replaces the original blade and allows you to retain the click adjustments that i have always enjoyed about the Ruger site. It as Fermin describes is a Glare eliminator.

Here are some pictures to explain how it works. By tHe way it works fabulously. Fermin really Knocked it out of the park with this one i do beleive.

Big Hairy 500L with a number 6 on it.

Here is a close up of the rear Face

Here is the mounting Mechanism.

Here is the trough at the top. Notice how they are funneled and angled forward to collect light to from the outline of the front site.

We have them in all neccesary heights.

.390 is the standard. they extend or retract the height in .025 increments. .390 std .415 and .440 tall. there is a low profile for those of you with short front sites as well. .365 and super low profile. 340. I make them in various widths to accomodate the length of barrel. a .120 slot is perfect out to 5 1/2 length for aperfect site picture. However i suggest .110 for 6 1/2 and .100 for 7 1/2 to 10 depending on your preferance. However for you guys that like the 10 1/2 ers like i do such as the super blackie in 44 and 357 Max , The .340 Tall and .090 wide is absolutely Bitchin!

These work well with the single six and all of the redhawks and GPs.

There is so much more to talk about.

.jpg)

.jpg)