|

|

Post by harveylogan on Aug 13, 2024 18:49:56 GMT -5

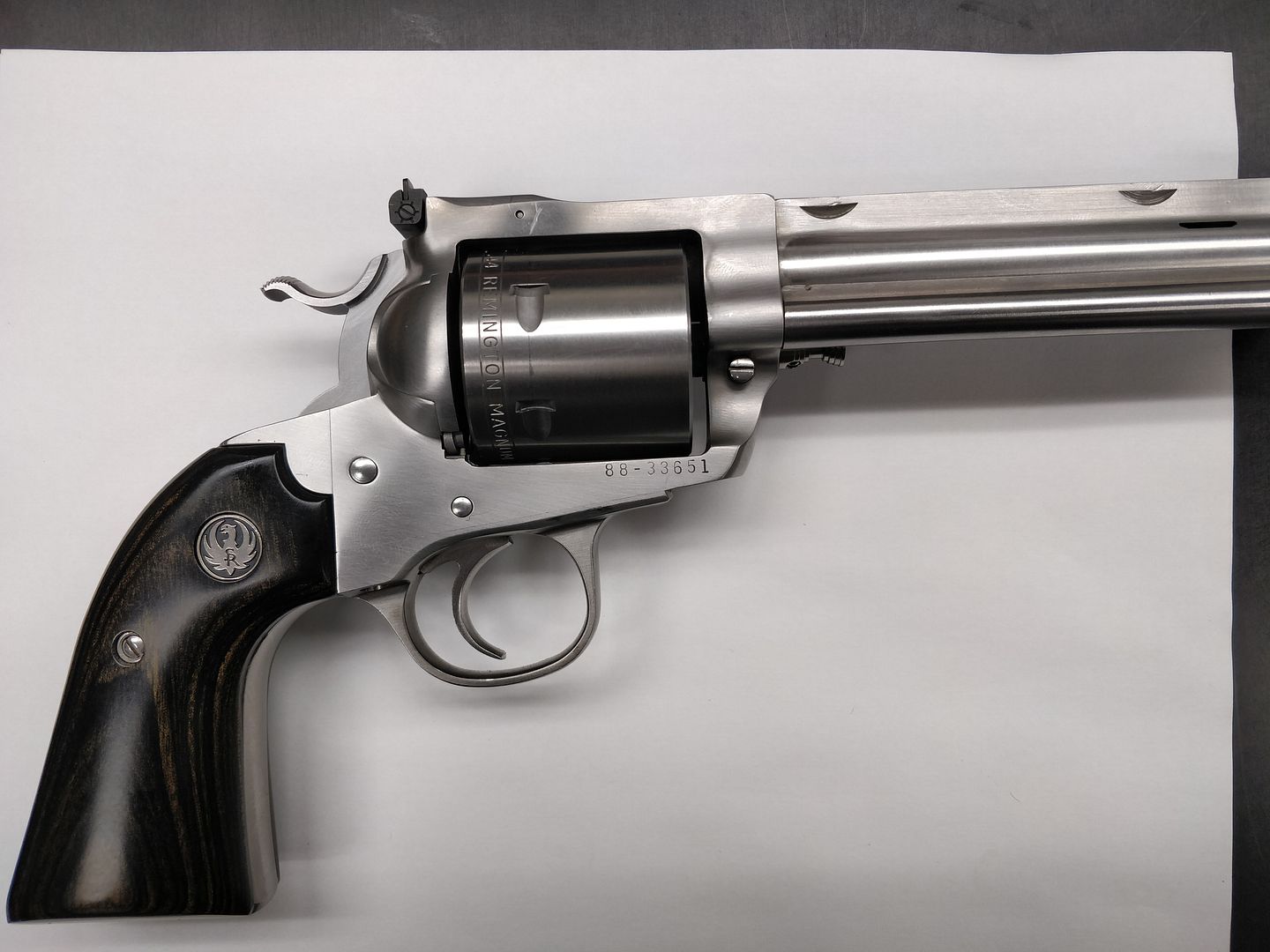

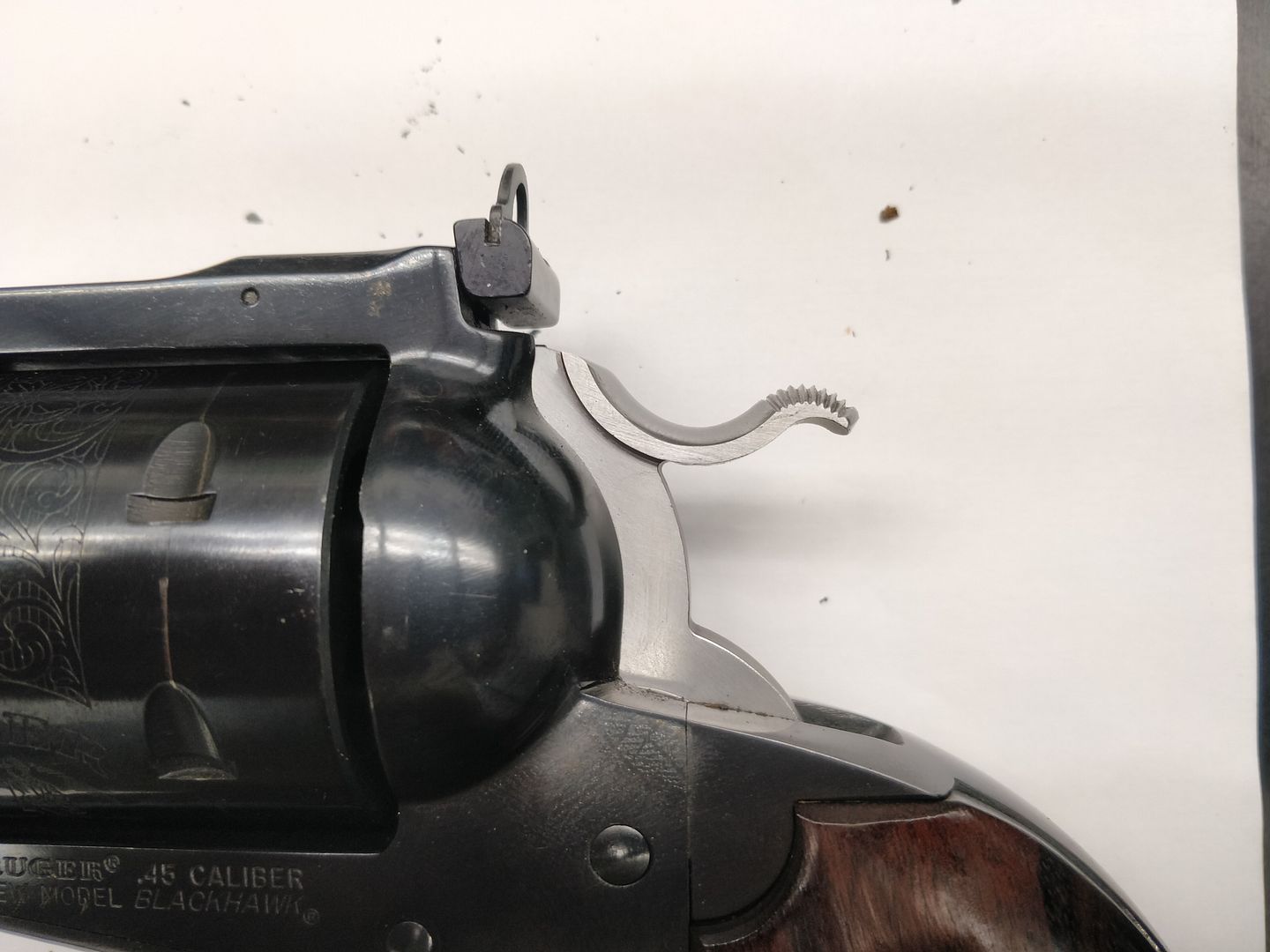

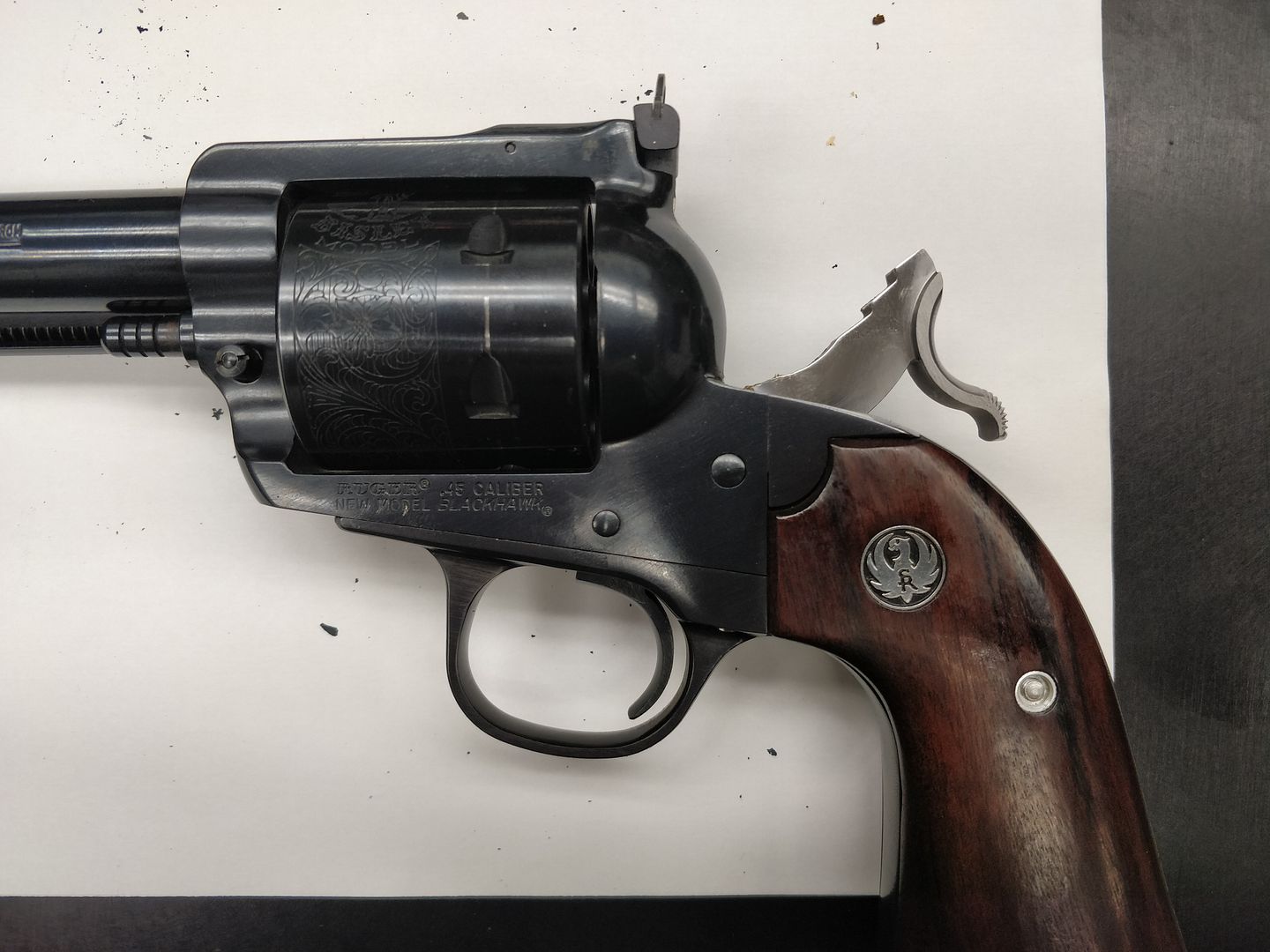

Spent the day changing out a Clements Bisley Hammer & Trigger… 😳,,, for a RW Bisley Super Hammer & Bisley Trigger. I aquired this OM Blackhawk from one of our fellow enthusiast ~ 2008 aquired with the brass grip frame, Clement hammer/trigger and Lett fancy walnut panels. I have enjoyed it, however the hammer always seemed a little short & small to me,,, aesthetics in the Large Frame Blackhawk. As Aquired:  Along came this guy Ronnie Wells with a Bisley SUPER hammer & trigger. I was blown away at the overall quality of the Hammer/Trigger. Ronnie has built it with the boss being a few thousands added to each side. It didn’t fit right off, but a few careful passes with the Diamond flat and it was in,,, with virtually no slop. The tolerances are simply amazing. I like the Bisley Spur, but I also like the SUPER Spur.    Did go ahead and install the Clements Bisley Hammer/Trigger into a 1960, MEDIUM FRAME, 357M flattop. They fit much better in the Medium Frame,,, IMO.  Absolutely impressed with the quality of RW parts. |

|

|

|

Post by bisleyfan41 on Aug 13, 2024 19:03:00 GMT -5

Beautiful sixgun! Ronnie's stuff is simply perfection. Congrats.

|

|

|

|

Post by wheelyfun45 on Aug 13, 2024 20:55:45 GMT -5

Wow, I LOVE that Flattop 357!!

Wouldn't mind seeing a thread devoted to that beauty

|

|

|

|

Post by contender on Aug 13, 2024 21:24:54 GMT -5

Yep,, Ronnie's work is impressive & designed with SHOOTERS in mind. I have a couple of his g/f's & other stuff myself. No surprises in your posting!  |

|

|

|

Post by drycreek on Aug 14, 2024 21:20:20 GMT -5

I have a Blackhawk in .41 mag with Ronnie right now. It will look something like the first pic harveylogan posted when it’s finished. Can’t hardly wait !

Nice looking revolver Sir !

|

|

|

|

Post by x101airborne on Aug 16, 2024 4:28:01 GMT -5

All the gear Ronnie makes is squared away and wired tight. I bet he went through 50 iterations of that hammer before he was happy. I call that hammer "Mr. Fat Back" and cant wait to get my hands on one for the new models. You should have seen the R&D he put into just the striations on top of the hammer! Talk about getting it right or not at all!

|

|

|

|

Post by RDW on Aug 18, 2024 12:17:38 GMT -5

All the gear Ronnie makes is squared away and wired tight. I bet he went through 50 iterations of that hammer before he was happy. I call that hammer "Mr. Fat Back" and cant wait to get my hands on one for the new models. You should have seen the R&D he put into just the striations on top of the hammer! Talk about getting it right or not at all! I have to be that way Trey. You should see the crap im getting in here for parts man. These Things look like a monkey took a file to them after they were used to test out the latest bomb dropping technology from 30 thousand feet into a flowin volcano and then packaged up as usable parts. You Know! Here is what i have come up with. Quite a few changes. Here is mine on the left that is not even prepared yet, and factorys on the right, and this one is one of the better i have received. as i normally do , the sides are cleared .006 thou for no scratchin so i can blue the whole thing or case coloor with out yukkin them up after 3 shots fired. My center pin hole is exactly .204 and bearing surface all across the width of the hammer. The serations are 10 degrees apart and all cut to the center as i described in another thread.  They are starting to look like they are cast into the hammer now rather than cut. Bluuuuch!  I like mine to flow and swoop. im using 9 serations. They are using 6 and a half. hahaha.  The groove for clearing the hammers strut on the factory is not nessacary and opens in my opinion more opportunity for guck to intrude the mechanism. On mine it is .025 more than any version of grip frame to hammers strut i have been able to test, so why have that giaint slot .  The single six bisley spur was a chore because i wanted it to follow the back of the recoil sheild and flow with the gun.  I THINK I GOT IT! And course it is semi even with the ears of the grip frame and not down in a trough.  Here is a factory for comparison.  Same thing on the full size.    Been a lot of work but im not done yet. Look at the pic above. that is a full size frame and the hammer is that height to accomodate the shorter mid frames. I dont like it so i am going to make a full size that goes to the top of the hammer trough and then i will feel better. That will give me a bit more sweep to the top with my bisley curve. As a matter of fact i have 4 in the oven tempuring as i write this. hahaha. Just cant leave it alone. One day a couple of months back, Dave clements said that he was anal about details and i fell out of my seat laughing. I said unfortunately i resemble that statement! Gosh i love David. Such a great dude. More to come as i geterdun. R |

|

|

|

Post by singleaction on Aug 18, 2024 14:10:43 GMT -5

Holy smokes, Ronnie! Those hammers of your look sexxeeee! Wow!

|

|

|

|

Post by RDW on Aug 18, 2024 17:56:00 GMT -5

Holy smokes, Ronnie! Those hammers of your look sexxeeee! Wow! Thankyou Sir. Its been a lot of work but definately worth it! Now my Sunday is complete. This is one of the 4 i was talking about in the previous post. Here is a Random Revolver i have in Here for a Big Bore Linebaugh conversion that has been waiting on this development to be finished. I have everything else ready to put this mammy together, Cylinders , Barrels, Grip frames etc, etc, etc. Just couldnt get my hands on a descent Hammer. It had one from the factory but it wasnt what i wanted to put on this special run of tribute revolvers. I have the triggers cut out as well and they are set back further and longer so they fill up the trigger guard and turn the back of the Trigger guard into a stop as well. Just fine little details that i beleive are important. The spur now sweeps the way i want and the inner geometry works just perfect. I moved the spur forward .050 thou to get it closer to the back of the frame. It makes the cocking motion more fluid and helped the leverage more to the positive side of the begining of the motion. When the spur is to high or too far back it takes more pressure to get the hammer moving backward because your thumb is having to reposition back behind the centerline of where your hand rests on the grip frame.. No repositioning of the hand on the grip. It feels like it requires about half of the force now to get it moving. I moved the pawl hole up in angle .75 of a degree to raise the pawl arm a smidge. I leaned the bolt plunger forward 1.1 degrees as well. It makes the bolt trip sooner and the timing is forward so you or the end user can tickle the upper leg of the pawl for perfect timing. It works fantastically. AND IM FRIGGIN DIGGIN IT! I feel like i just gave birth. Man it feels good to finally be satisfied with this project. Now time to pumpem out and complete this run of 500 Ls. This hammer is in the raw but will soon turn a bit darker. Hahaha. CCH or shiny Blue. Just needed to see it fit several platforms to say im all done with the development. You should see the pile of scrap i made on these. LOL>   R |

|

|

|

Post by drycreek on Aug 18, 2024 21:20:27 GMT -5

Great looking work Ronnie, you just don’t stop until you get it right. Admirable quality in any profession !

|

|