Aggie01

.375 Atomic

max

max

Posts: 1,779

|

Post by Aggie01 on Oct 2, 2009 13:13:23 GMT -5

I'm gonna try my hand at making a set of grips. I want to try a bisley set. My plan involves making a waterjet cut duplicate of a set of hogue bisley grips I have that are slightly oversize to all of my grip frames.

I hope to take delivery of a 3/8" thick perfectly flat bisley grip made out of trash material late next week.

Grip makers -

How do you guys make your blanks? Would something like this be a marketable blank at a large scale?

How about the non grip makers? A set of blanks with no contour that should match the outline of an existing part? Marketable at a small scale?

Let me know if there is interest in this.

I don't know price yet, so obviously that drives things, but when the quote comes back, I'd like to know if I could move more than a couple of these pieces before I commit.

|

|

|

|

Post by Markbo on Oct 3, 2009 12:19:50 GMT -5

I'd be interested. The only really important measurement to me is the thickness... I don't need a cut out since that is all removed during sanding anyway... at least that's how I do it... probably not right for someone that knows what they are actually doing.  |

|

caryc

.375 Atomic

Posts: 1,055

|

Post by caryc on Oct 4, 2009 12:05:51 GMT -5

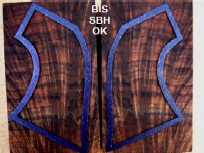

I'm gonna try my hand at making a set of grips. I want to try a bisley set. My plan involves making a waterjet cut duplicate of a set of hogue bisley grips I have that are slightly oversize to all of my grip frames. I hope to take delivery of a 3/8" thick perfectly flat bisley grip made out of trash material late next week. I must be a little dense because I don't quite understand your statements above. What is the 3/8 thick perfectly flat bisley grip made out of trash? Are you by any chance talking about a template? I also don't understand making a water jet cut set of grips. Maybe I've got the wrong idea of what you are trying to do but water and wood do not mix. Any set of blanks for grips needs to be dry. Preferably at 6% to 8% moisture content. You need dry wood to prevent any warping or checking in the finished grips. You don't want to introduce any water into the wood. Before thinking about selling blanks, you might want to check on the prices of wood. It's not all that easy to get premium wood, especially dry wood. You did ask about what grip makers thought so I'll tell you. I would not buy semi finished (as I somehow think this is what you are referring to) blanks. I'd rather buy wood in board or chunk form and cut the grips from it where I see fit. This is a set of blanks or at least what I call blanks.  |

|

|

|

Post by Mark Terry on Oct 4, 2009 20:19:31 GMT -5

Are you talking about a synthetic, Aggie? Maybe Micarta or similar?

By the way Cary, I FINALLY visited your website. Very impressive!

|

|

Aggie01

.375 Atomic

max

max

Posts: 1,779

|

Post by Aggie01 on Oct 5, 2009 9:25:55 GMT -5

Cary - Thanks for the comments.

I was thinking waterjetting just cause it came up in a conversation and I have the opportunity to try something out. I was gonna use wood for the "trash" pieces, just to see what they look like, but only deal with synthetics if I want to actually pursue it. (I have some Lexan somewhere I was gonna give him to try, but couldn't find it - 100% optically transparent grips would be "different" )

I hadn't thought about the problems of injecting water into the wood, the reason I wasn't going to use wood was that I just don't have the "artist's eye" like you and some others do when it comes to picking out wood.

|

|