|

|

Post by whitworth on Oct 18, 2013 15:39:18 GMT -5

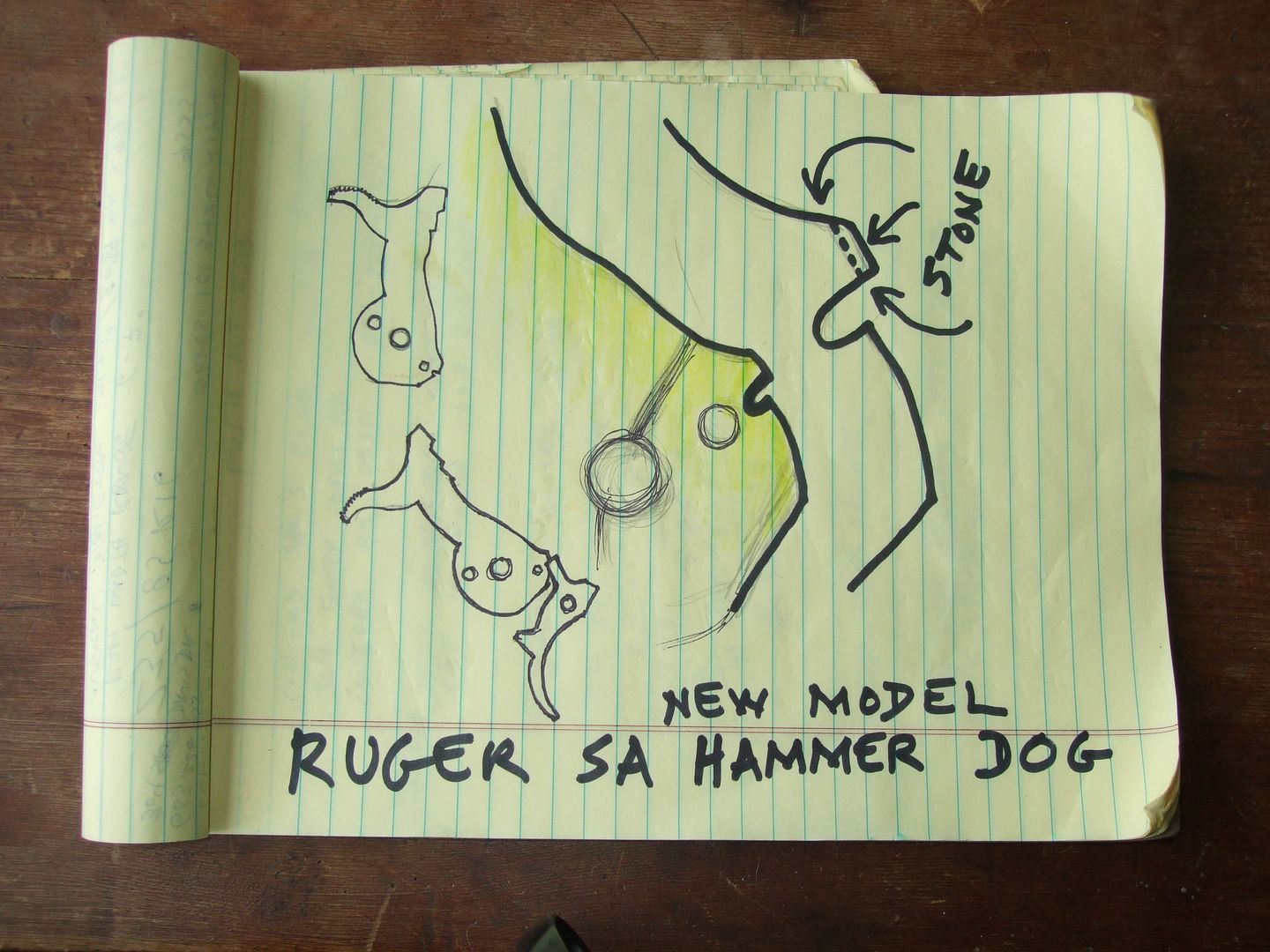

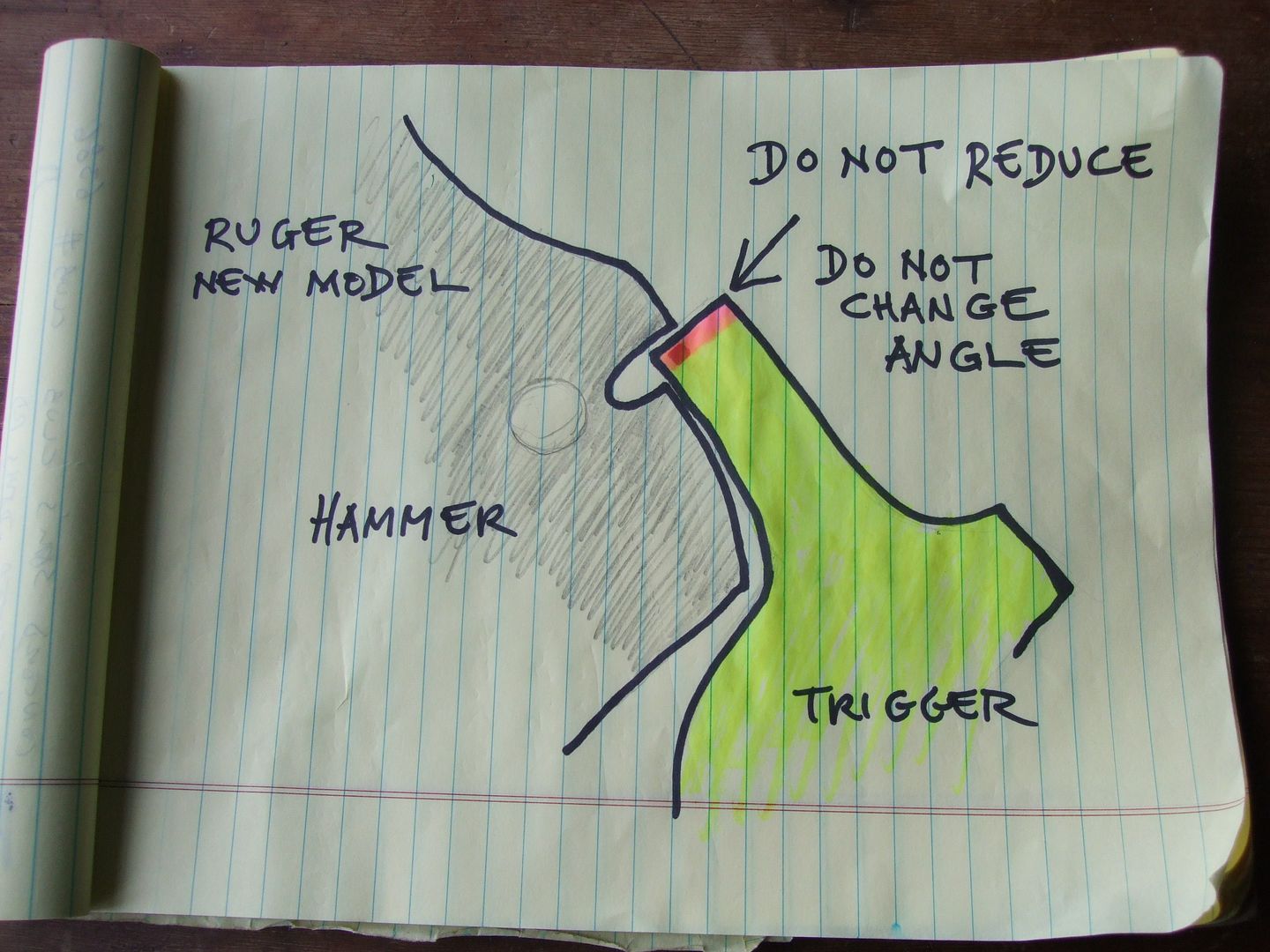

David Bradshaw asked me to post these drawings of what he refers to as a "country simple" New Model trigger job. Enjoy. Photo #1 1) HAMMER: Reduce DOG (full cock lug) on hammer. Proceed with patience. Re-assemble and test letoff frequently.  Photo #2 2) TRIGGER: Polish SEAR TIP only if necessary to remove burrs or roughness. Polish flat below sear tip if necessary to remove roughness. Do not change angle of tip, under risk of losing REGAIN feature of factory engagement angles. Do not reduce sear tip, as this will shorten HAMMER FALL and produce gaposis between hammer and grip frame at COCK. Do not polish any other surface unless you are experienced at this work.  |

|

|

|

Post by alukban on Oct 18, 2013 15:48:46 GMT -5

These pics are gold  Thanks! |

|

|

|

Post by buckheart on Oct 19, 2013 7:54:00 GMT -5

A while back I picked up an older NM Black Hawk in 45colt from Gunbroker. It came to me with rubber grips and a bunch of surface wear. No matter as the bore was great and the price was right. It had the lightest trigger I had used up until that point. I finally had a gun that seemed to hit exatly where I pointed it, and I happily ran several hundred rounds through it. As time passed it seemed that the trigger got even lighter, but I figured that was just me getting used to the gun all the more. One day while shooting i went to put the hammer down on a live round and touched the hammer before my finger was on the trigger, bam, she went off. She had develpoed "push off". Two Dogs hooked me up with a new hammer and trigger and all was back to normal, though not as light a trigger pull as it had before. Since then I have put a powers custom hammer and trigger in it which has been great. Here is a picture of the old failed hammer and trigger. Any comment on what they might have been trying to achieve with the notch in the trigger? Also looks like maybe some welding went on in the hammer? Or maybe just metal just peaned over from use?  |

|

dmize

.401 Bobcat

Posts: 2,834

|

Post by dmize on Oct 19, 2013 8:27:34 GMT -5

Thanks for the diagram David.

Buckheart,I am without words.

|

|

|

|

Post by bradshaw on Oct 19, 2013 9:46:07 GMT -5

Thanks to lead slinger Max Prasac for posting drawings, and again to Lee for this forum.

Buckheart.... beau coups thanks for posting photos of a true FUGITIVE TRIGGER JOB. Fortunately, the used revolver you bought is accurate. That we can live with. Trigger & Hammer are replaceable. This hammer & trigger cannot be saved. To restore both the hammer dog and the trigger sear tip with stones would severely shorten HAMMER ARC at full cock. This would leave unsightly gap between hammer and grip frame, and cause nauseating hammer drop between the cocking stroke and sear engagement. To my knowledge, as long as the family owned Sturm, Ruger, the Rugers never used surfaced hardened parts. And I haven't heard of a change in that approach. This emphatically includes to this day the heat treated hammer & trigger. (Note that S&W case hardened hammer & trigger engagement surfaces are a couple thousandths inch deep, and that to cut through the case carburizing is sure to doom sear engagement.)

Buckheart, if your hammer was welded upon, hardness through the parts may vary. Someone with the skill might restore it, but it will cost more than a new factory part. When we speak of a fugitive trigger job, we refer to ENGAGEMENT ANGLES as well as any other work. By definition a fugitive engagement angle doesn't last.

As to the meaningless groove cut in the trigger sear tip, it testifies only to the ignorance of the person performing the work.

As to attributing discharge (without touching trigger) to incorrect or worn engagement, this is only possible with a trigger spring too light to reset trigger. Unless the trigger is pressed, it rebounds at hammer fall, and as the trigger rebounds, the transfer bar drops below firing pin. Your description suggests that the bad medicine on hammer and trigger includes the trigger spring.

David Bradshaw

|

|

|

|

Post by foxtrapper on Oct 19, 2013 10:16:57 GMT -5

Pics are copied placed on thumb drive and going in the vault! Thanks David :-)

|

|

|

|

Post by onegoodshot on Oct 19, 2013 10:51:56 GMT -5

Thanks for the illustration!

What do I use to stone??

Will an Arkansas wet stone work?

Do you use oil like you use with a knife?

Do you try and keep sharp flat angles or do you want to round it at all?

|

|

|

|

Post by bradshaw on Oct 19, 2013 11:22:36 GMT -5

I have used a variety of stones for dressing the HAMMER DOG. India, Arkansas, Ee-Zee Lap diamond-impregnated steel. I find the Spyderco white ceramic stones with dead-square edges on each end. A corner can only be addressed with a dead square stone. The slightest radius defeats a square notch. The stone must be dead flat. Synthetic stones such as the India Combination (red/gray laminated) and EeZee-Lap tend to be FLAT. Many Arkansas stones have dips or waves or rough spots. Carborundum stones generally are coarse and too soft for real trigger work. (Note: as long as you dress only the hammer dog, carborundum----such as the Norton----is useful.) Whenever I use a stone, I use oil. Or water; when I use water, I lube with detergent. This is to float out particles and not plug the stone. Oil or water-with-detergent on the stone applies as well to knife sharpening.

The work must be held square to the stone. A small clamp set at correct angle to drag on the stone helps hold the work square. Practice squaring the tips of a few screwdrivers. If you can't get the screwdriver tip square, leave the trigger work to someone with appropriate skill.

Persons who have used a chainsaw all their life, but cannot hold the angle consistent when sharpening the chain with a hand held file, should not attempt trigger work.

Later can get into more detail. First, we must understand hammer-trigger engagement.

David Bradshaw

|

|

|

|

Post by boxhead on Oct 19, 2013 19:54:04 GMT -5

I stone the hammer engagement to .025" or so and always have a safe crisp trigger. Bend the trigger spring arms to land on a 3# pull.

|

|

|

|

Post by oldschool on Oct 20, 2013 16:14:50 GMT -5

Nice illustrations, David. Thanks, Max, for uploading them here. I've read about this process many times, but pictures tell the story.

|

|

|

|

Post by squawberryman on Apr 9, 2015 18:36:02 GMT -5

Re-up for those interested. This should be a requisite bookmark for all interested.

|

|

|

|

Post by mike454 on Apr 9, 2015 19:04:23 GMT -5

One day while shooting i went to put the hammer down on a live round and touched the hammer before my finger was on the trigger, bam, she went off. She had develpoed "push off". Was something else wrong with the gun? A new model shouldn't fire unless the trigger is pulled, the transfer bar should prevent the gun from firing from hammer push off. |

|

|

|

Post by Frank V on Apr 9, 2015 21:09:33 GMT -5

Thanks for the picture, it's worth a thousand words.

|

|

|

|

Post by bradshaw on Apr 9, 2015 21:22:50 GMT -5

First, my thanks to squawberryman for finding and posting these drawings.

mike454.... without seeing the gun which supposedly fired by pushing the cocked hammer, one can only speculate how it could fire. The trigger spring would immediately reset the trigger, dropping transfer bar below firing pin. Wreckage done to the hammer & trigger in buckheart's photo may be repeated elsewhere in the gun.

Usual modus operandi of a purple-ass baboon as he butchers hammer and trigger is to leave the frame alone. But, part of a cannibal's genius is to mess up moving parts wherever he sees them, including lockwork other than hammer & trigger. I've replaced a few rotten "trigger jobs," but, until the photo posted by buckheart, never saw cannibalism this bad.

The drawings and notes should make plain that trigger work be done right, or not at all.

Principle of REGAIN: trigger sweeps rearward at hammer fall.

David Bradshaw

|

|

Paden

.375 Atomic

Lower Goldstream Creek

Lower Goldstream Creek

Posts: 1,132

|

Post by Paden on Apr 9, 2015 21:37:13 GMT -5

Usual modus operandi of a purple-ass baboon as he butchers hammer and trigger is to leave the frame alone. But, part of a cannibal's genius is to mess up moving parts wherever he sees them, including lockwork other than hammer & trigger.... David Bradshaw Lol! <shakes head> |

|