|

|

Post by buckheart on Feb 9, 2013 18:41:36 GMT -5

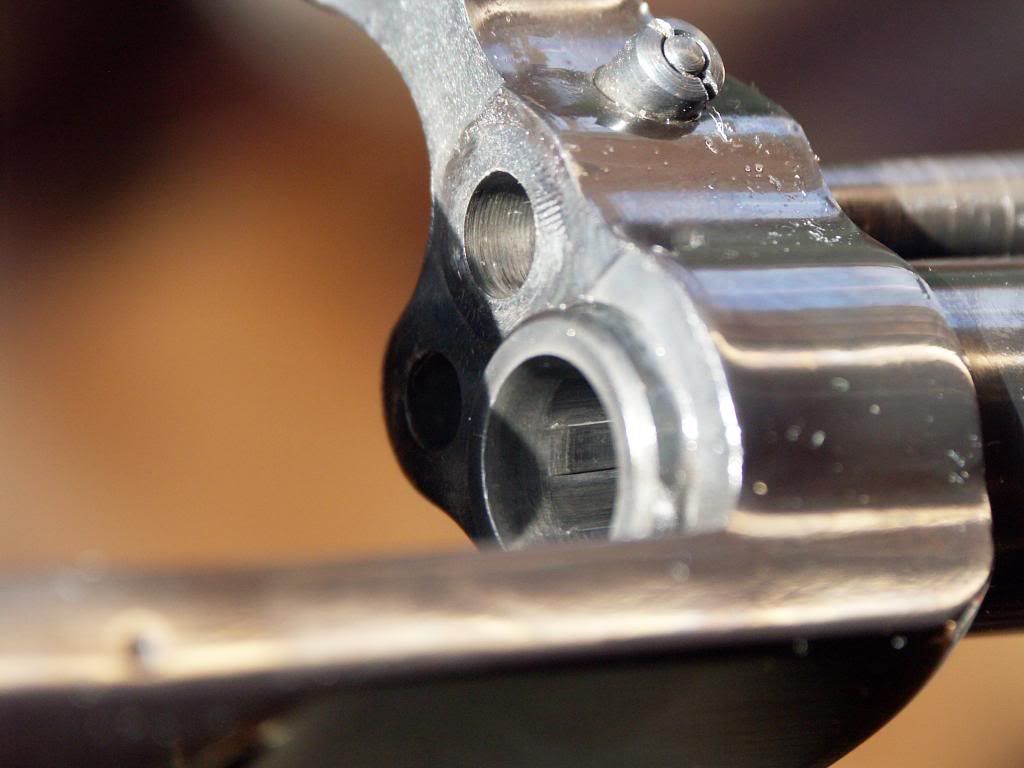

Smith&Wesson 629 Performance Center Hunter   |

|

|

|

Post by bradshaw on Feb 9, 2013 22:32:12 GMT -5

I stand ready to be wrong....

1) Axehandle----Lint farm at "Taylor throating," by Jim Stroh. Beautiful Stroh work covered with sweater or belly button lint. I prefer grooe-diameter freebore, but if this forcing cone makes your revolver a shooter, have at it.

2) Buckheart----(Unburned 4227?) BFR .45-70 with appropriately short forcing cone. However, the leade is stepped, or ringed, and and smooth transition at this very point is golden. Pretend you are the bullet. This is a candidate for cleanup, although your .458 pumpkin ball may not notice.

3) Buckheart----Cone leading at leade. Light spitting at 9 o'clock may indicate chamber OFFSET. I am ready to be wrong. The leading conceals all-important cone-to-rifling transition. Until lead is removed, we cannot view this detail. (Thanks for pix from right and left, with leading all-around.) If your chamber throats were tight, leading may string along shoulders of rifling into bore, so I think this isn't problem.

Possible velocity overstepping alloy or lube. Bullet tipping in throat?

David Bradshaw

|

|

COR

.375 Atomic

Posts: 1,529

|

Post by COR on Feb 10, 2013 8:26:47 GMT -5

I'm not sold on line boring at all having shot 4 different customs without it the were built correctly from the ground up that shot as well or better than a few done by a popular gunsmith with that added charge of line boring. Maybe some voodoo and marketing have caused folks to claim its virtue... I'm just not buying it yet but there is always room for education and changing attitudes.

Thanks for some points to ponder more... As a hunter much less than a target shooter I just need all shots on a dinner plate to hit deer but we all have the same quest for accuracy. I just don't get any spotter rounds in the field!

Great discussion.

|

|

|

|

Post by bradshaw on Feb 10, 2013 9:40:45 GMT -5

COR.... your writing reveals a keen interest in having a fine revolver and a revolver of mediocre accuracy cannot be fine. I had long been at revolver hunting before handgun silhouette came along. Riflesque accuracy was mandatory, not optional, in our sixguns. The long shots we play at invariably contribute to closer shots made clean on game. On this, if I may be so bold, I believe I speak for you, along with various other practitioners of the art on this forum.

However a manufacturer or gunsmith bores cylinders, coordinating chamber-axis to bore-axis is the object, and cannot----as was done for a period in the 1980's----be left to the forcing cone to correct. Dan Wesson Arms did a magnificent job on some unlikely machinery; doubt DWA line-bored. S&W did masterful work for generations without line-boring. To reiterate, line-boring is one tool in the box.

Buckheart.... ring of lead in 629 at front edge of forcing cone? I can't be the only one wants to know the ingredients of this cake...

We're not done with the subject of revolver accuracy, by a long shot.

David Bradshaw

|

|

COR

.375 Atomic

Posts: 1,529

|

Post by COR on Feb 10, 2013 9:59:18 GMT -5

I should have clarified my accuracy needs. One way I have established my own max EFFECTIVE range is by using standard paper plates. I use field positions in wooded settings and continue to back up until I miss the flat white of the plate. The crinkled edges are not acceptable as a killing shot. 12 shots, all must be on, if not, I stop. It's humbling and requires that amount of discipline to let the deer walk that is 5 yds out of my range. By shooting where I hunt I get the shadows and a mental range card with trees as my reference points.

It's been said before me by the grand old man himself that long range shooting is the test of any "accurate" revolver. My steel swing plate is the tool of fun for that job when shooting the 800 yd field at the family farm. Not at 800 everyday, although at 400 can be done surprisingly consistently in most any hands with practice and some dry fields for impact.

Thanks for the great feedback.

|

|

mark

.30 Stingray

Posts: 207

|

Post by mark on Feb 10, 2013 11:40:57 GMT -5

This is a question loosely related to the topic at hand, but I was wondering, in the presence of a less than optimal forcing cone geometry, will moving to jacketed or very hard cast, truncated cone style cast bullets mitigate the effects over shooting a standard SWC design cast at about 12-18 BHN? I have $.02 to add. Speaking on 38 & 44 caliber, I started out loading and shooting SWC designs. As you may suspect, some guns grouped better than others. Back in those days, I had no idea of the dimensional designs and their affect on accuracy. It was with some reservation that I tried other designs such as the truncated cone. Group size got smaller in those guns that "lacked accuracy." I cast and load the Thompson design 429244 (often without a gas check) in my 44 magnums. It often proves more accurate than the Keith. I think that has to do with the smaller diameter first driving band. Mark |

|

|

|

Post by hammerdown77 on Feb 10, 2013 14:20:54 GMT -5

Mark,

That has been my experience with the Keith bullets, they shoot good in some guns but not in others. I've been using the 429421 of late. As you mention, I've found that often simply going to a truncated cone bullet brings the accuracy in those particular guns I was hoping for. Never really understood why until all these threads about forcing cones and alignment.

The guns that shoot the Keith well, tend to shoot every style bullet well. My Freedom Arms model 83 made in the early 90's is one of those. I don't think you can feed it a load that won't print tiny groups on the target...

|

|

|

|

Post by buckheart on Feb 10, 2013 19:48:17 GMT -5

First I must say to all the PHD type pistol folk on here that I do appreciate your input. Though I have always shot and always hunted, close to fifty years worth, it was always with a rifle or shot gun. So though I am some what of an "old guy" I am certainly a pistol newbie. Just found the time to do all the paper work and get my pistol permit in 2008.It was kind of a bucket list type thing. Since then I have been totally infatuated by anything with a barrel under ten inches. I spent 2008 learning to hand load and working up a hunting load for my 44. In 2009 I took this little spike with my 629. At 42 yards I took out most of both lungs using 22 grains of IMR4227 and a 240 gr. XTP.  Shortly after that hunting trip I found this forum and started to get more interested in using cast bullets. I picked up some 265 grain semi wad cutters, Lyman mold #429244, with gas checks and used the same loading as I had used with the XTP bullet.  First six were very accurate and of course the accuracy fell off the more I shot, as the forcing cone leaded up as shown in the pictures I previously posted. I put this out on this forum before and most people thought it could have been the result of the barrel being constricted where it threads into the frame. The same load in a Super Blackhawk and in a Vaquero showed no signs of leading. I spoke with the person that cast the bullets and he said that he cast them fairly hard as he figured people would be pushing them. He suggested softer non gas checked bullets. Since then I have run only clad bullets through this gun with no problems. Of course no leading and no excessive copper build up. The following four pictures are of the 629 minus the leading.     The last two are of a super black hawk that has shot the same load and bullet with no lead build up.   Bradshaw thanks for your input. And by the way the spent powder on the BFR was Varget. |

|

|

|

Post by bradshaw on Feb 10, 2013 21:20:25 GMT -5

Buckheart.... thank you for the excellent pix. Amazing, how the reamer rings show up in one exposure and not another. Without going back to your first pictures, looks like the bullet tears on those rings. A ring on a cone becomes a step, or ridge. This is a common flaw in forcing cones, and these edges introduce the LEADE of the rifling. The leade----the ramp of the LAND----looks rough.

S&W Performance Center gun, eh?

Cause of this leading is not an over-torqued barrel.

You may be able to smooth out the rings with very fine crocus cloth on cone attachment of Lewis Lead Remover, providing the Lewis cone attachment matches forcing cone angle. To ream deeper runs risk of bullet unsupported between throat and rifling.

Before you roll up your sleeves, call S&W service, which ought to make good, set back barrel same as to correct forcing cone erosion. I've had barrels set back at S&W and Ruger to eliminate forcing cone erosion; I forbade replacement of those superb barrels.

A third alternative would be to have a good smith remove just enough to clean up the tool marks----not one fingernail more.

David Bradshaw

|

|

jwp475

.375 Atomic

Posts: 1,100

|

Post by jwp475 on Feb 11, 2013 9:26:44 GMT -5

David is spot on. I have had Jack cleanup forcing cones for me on factory barrels. Here are a few pictures Of my two M-29-2's   |

|

|

|

Post by Lee Martin on Feb 11, 2013 14:37:30 GMT -5

Dad and I have toyed with a few forcing cone angles and settled on 11 degrees (we've gone as low as 5). As David and JWP indicated, concentricity and proper depth is key. We cut ours relatively shallow, concentric, and to a mild 11 degree lead (see photo below). Never had to the need to free-bore except on a couple of over-torqued factory Rugers. Great discussion here and I really appreciate all the input. This thread goes beyond the over-used buzz-words like "line-boring" to explain the why and how of revolver accuracy.  -Lee www.singleactions.com"Building carpal tunnel one round at a time" |

|

jwp475

.375 Atomic

Posts: 1,100

|

Post by jwp475 on Feb 11, 2013 14:56:59 GMT -5

That is an excellent forcing cone. I bet you never have a "slow" or inaccurate revolver with this type of precission

|

|

|

|

Post by buckheart on Feb 11, 2013 20:48:17 GMT -5

Took the first step towards correcting that forcing cone issue. I filled out the internet form for a repair and am awaiting the shipping tag from Smith&Wesson.

|

|

cj3a

.30 Stingray

Posts: 403

|

Post by cj3a on Feb 11, 2013 21:02:21 GMT -5

David, i been think about this thread for some time. I have been going thru the steps I think a manufacture would use to make the cylinder and were the errors in aliment would start. The cylinder pin hole to me seems to be the start of the problem. If one drills and reams the hole it is next to impossible to have the hole parallel and perpendicular to both faces of the cylinder. Now if the cylinder was fixture on the O.D. the chambers would not be parallel with the cylinder pin. One would have to turn between centers to correct the misalignment from drilling. I curious on how manufactures deal with these problems.

|

|

|

|

Post by bradshaw on Feb 12, 2013 8:54:47 GMT -5

cj3a.... If holes could not be drilled straight, a revolver could not be made, as the cylinder face would bind against the barrel. The radius between center pin and chamber must match radius of center pin and barrel. Lateral chamber-to-bore alignment is determined by the stop notch on the opposite side of the cylinder. The hole for the cylinder stop (aka bolt latch, catch) in the cylinder frame must correspond to the bore axis.

A swing-out cylinder has a yoke (aka crane)----pivot and cylinder axle must align chamber-to-bore vertically and laterally.

Perhaps to shoot straight it is not necessary to understand how a revolver builds accuracy. However, in my simple mind, to shoot straight I must trust my equipment and not think about it, to READ and SQUEEZE the SHOT without a thousandth distraction.

David Bradshaw

|

|