Post by Lee Martin on Feb 20, 2024 20:43:38 GMT -5

The post in the lounge section concerning .264 Win Mag brass got me thinking about a rifle we did in the 1990’s. There’s a bunch of backstory here, so bear with me. In 1992, my dad built me a .264 Win Mag on a Mauser action. That summer, he was constructing a block garage at our country place and I was chosen to mix mortar and carry supplies. In return, he gave me a trued 98 Mauser action, a stock, a 60’s vintage Redfield scope, and a 6.5mm take off barrel we had in the shop. He also ground the reamer. My interest in the .264 stemmed from him having an old Winchester 70 in .264 and articles which pegged it as capable of eating barrels fast. But it also was fast and that appealed to me. We built the gun and surprisingly it grouped well. I’ll never forget the first time I touched off some Sako 140 gr factory ammunition. Plenty loud with plenty of blast...just the sort of thing a 20-year-old flips over. Its only drawback was the 22” barrel. That short tube couldn’t post the velocities I was after. Years later I screwed in a Shilen ratchet cut blank, dressed to 27.5”. Pouring Retumbo or US 869 powder, I finally got the elusive 3,200+ fps with 140 grain bullets. I guess that gun put 6.5mm on the brain back then.

In 1994, we came across a set of Lyman 6.5 Rem Mag dies. Probably paid $10 or $15 for them at a gun show or store. I can’t remember all the details. Like many of our projects, having the dies meant we needed the gun. In short order, dad ground the reamer and assembled one on a Mauser action. I seem to recall we used a Shilen blank, but as you’ll see in a minute, that wasn’t the case. Anyways, we worked with the rifle for months and couldn’t get it to shoot. 2.0” groups at 100 yards with every bullet/powder combination we could think of. Bullet weights ranged from 100 to 160 grs. The action was bedded, the Mauser was trued, and the Weaver scope seemed solid. I don’t know how many rounds we tested, but it was up there. Nothing worked. Eventually, we blued the barreled action and stuck it in the rack.

Last Sunday, I mentioned the gun to dad and he also remembers the frustration it caused. I figured I'd give it another try. This time, I wanted to form brass from more common magnum hulls. He has some Remington brass, but it’s soft and won’t last forever. I dug out 7mm Mag once fired and began pushing shoulders back. We found the best way was to not form the 6.5mm neck all at once. The shoulder is moved roughly 0.300”, which is a lot. Instead, we took his .30-350 FL sizer, removed the expander, backed the die out until it just touched the shoulder, and screwed it down one-turn per pull. Slow indeed, but the process set the shoulder to the correct position without creasing the wall. It worked, or at least so it seemed. Upon trying them in the gun, the bolt wouldn’t close. Neck thickness wasn’t a problem. The chamber mics 0.298” and the formed cases were 0.296” with a seated bullet. Comparing them to factory Remington gave us the answer. The shoulder on the new batch was almost 0.030” forward. Spring back was occurring from all the stress imparted in forming. And because the die has a relief cut for the belt, I couldn’t go lower in the press. Dad is going to make a short die, minus the belt, that’ll allow me to move the shoulder past where it needs to be to account for spring back. I'm also going to anneal the 7mm Mags before forming. That may eliminate the need for the custom die.

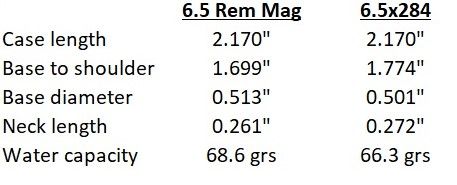

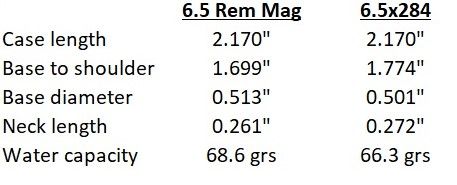

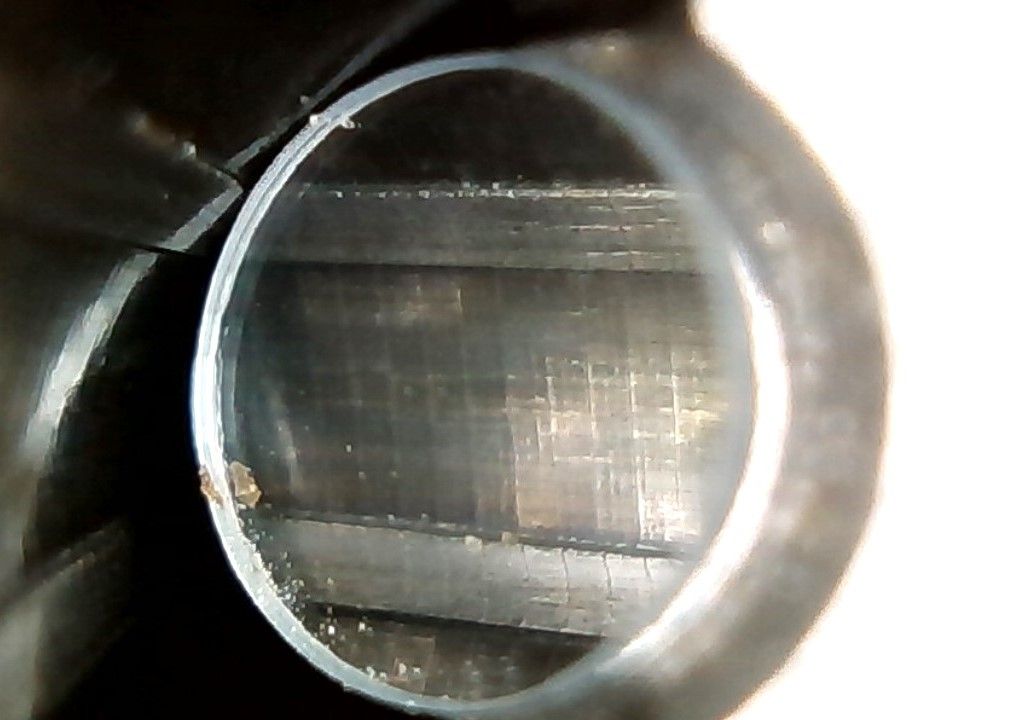

Next we borescoped the barrel on his gun. In 1994, we didn’t have a borescope and went on blind faith. What we found tells me the blank isn’t a Shilen. As you’ll see below, there are a ton of chatter marks, probably from the button. And it’s holding copper too. In the 90's, we used Shilen, Douglas, or ER Shaw blanks on hunting rifles. My guess is this one is a Shaw. The latter was for those done ‘on the cheap’. I’ll try it again this spring and see if it'll do better. I wouldn’t bet a dollar it will though. Onto plan B, which involves a rifle I got for Christmas 1994. We must’ve wanted to round out the short Rem Mag family that year, because he built me a .350 Remington Magnum on a Mauser. Fit to a Butler Creek synthetic stock, I know for sure this one has a Shilen SS tube. Why not make it a switch barrel? I’ll order a 1:9 twist from a reputable maker and revisit this long-forgotten cartridge. On paper, it should be capable of respectable accuracy. The 6.5x284 is very competitive in 600-yard F-class. And to my surprise, it dimensionally mimics the 6.5 Rem Mag. This is how they stack up:

They’re nearly identical. I feel with good brass, a standard-length action which doesn’t require deep seating, premium bullets, and a good barrel, the forlorn 6.5 Rem Mag can be capable of decent accuracy. Like dad’s, mine will have a 24” barrel. More to come.

6.5 Rem Mag formed from 7mm Rem Mag.

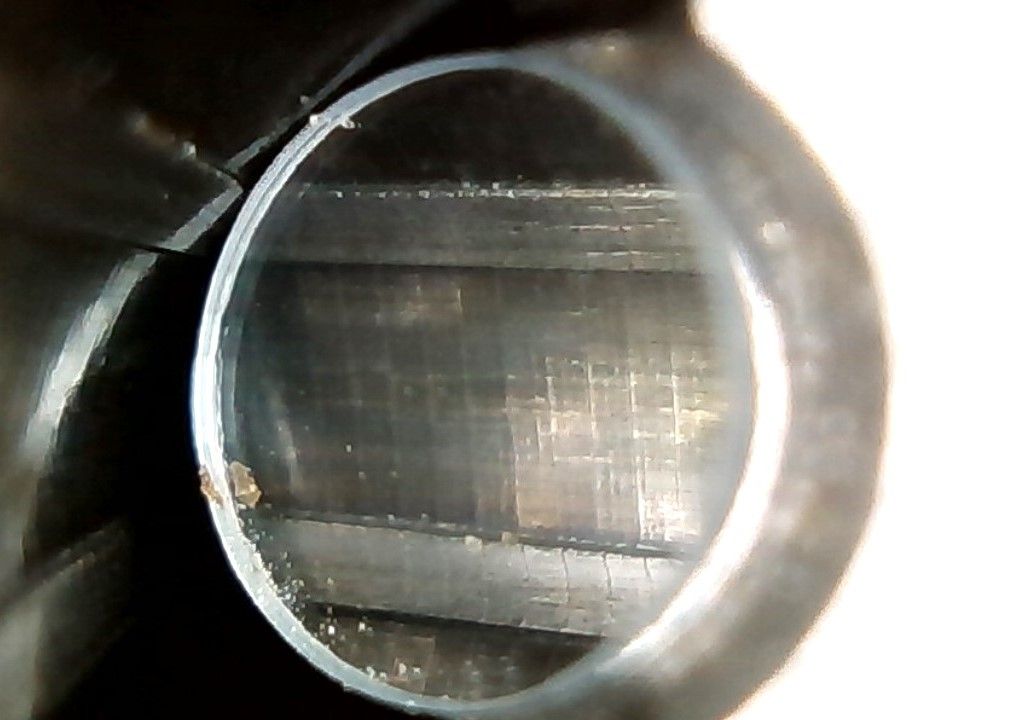

Inside the barrel of dad’s 6.5 Rem Mag. Notice all the radial chatter marks? Those may or may not be the cause of poor performance, but they don’t help accuracy.

-Lee

www.singleactions.com

"Chasing perfection five shots at a time"

In 1994, we came across a set of Lyman 6.5 Rem Mag dies. Probably paid $10 or $15 for them at a gun show or store. I can’t remember all the details. Like many of our projects, having the dies meant we needed the gun. In short order, dad ground the reamer and assembled one on a Mauser action. I seem to recall we used a Shilen blank, but as you’ll see in a minute, that wasn’t the case. Anyways, we worked with the rifle for months and couldn’t get it to shoot. 2.0” groups at 100 yards with every bullet/powder combination we could think of. Bullet weights ranged from 100 to 160 grs. The action was bedded, the Mauser was trued, and the Weaver scope seemed solid. I don’t know how many rounds we tested, but it was up there. Nothing worked. Eventually, we blued the barreled action and stuck it in the rack.

Last Sunday, I mentioned the gun to dad and he also remembers the frustration it caused. I figured I'd give it another try. This time, I wanted to form brass from more common magnum hulls. He has some Remington brass, but it’s soft and won’t last forever. I dug out 7mm Mag once fired and began pushing shoulders back. We found the best way was to not form the 6.5mm neck all at once. The shoulder is moved roughly 0.300”, which is a lot. Instead, we took his .30-350 FL sizer, removed the expander, backed the die out until it just touched the shoulder, and screwed it down one-turn per pull. Slow indeed, but the process set the shoulder to the correct position without creasing the wall. It worked, or at least so it seemed. Upon trying them in the gun, the bolt wouldn’t close. Neck thickness wasn’t a problem. The chamber mics 0.298” and the formed cases were 0.296” with a seated bullet. Comparing them to factory Remington gave us the answer. The shoulder on the new batch was almost 0.030” forward. Spring back was occurring from all the stress imparted in forming. And because the die has a relief cut for the belt, I couldn’t go lower in the press. Dad is going to make a short die, minus the belt, that’ll allow me to move the shoulder past where it needs to be to account for spring back. I'm also going to anneal the 7mm Mags before forming. That may eliminate the need for the custom die.

Next we borescoped the barrel on his gun. In 1994, we didn’t have a borescope and went on blind faith. What we found tells me the blank isn’t a Shilen. As you’ll see below, there are a ton of chatter marks, probably from the button. And it’s holding copper too. In the 90's, we used Shilen, Douglas, or ER Shaw blanks on hunting rifles. My guess is this one is a Shaw. The latter was for those done ‘on the cheap’. I’ll try it again this spring and see if it'll do better. I wouldn’t bet a dollar it will though. Onto plan B, which involves a rifle I got for Christmas 1994. We must’ve wanted to round out the short Rem Mag family that year, because he built me a .350 Remington Magnum on a Mauser. Fit to a Butler Creek synthetic stock, I know for sure this one has a Shilen SS tube. Why not make it a switch barrel? I’ll order a 1:9 twist from a reputable maker and revisit this long-forgotten cartridge. On paper, it should be capable of respectable accuracy. The 6.5x284 is very competitive in 600-yard F-class. And to my surprise, it dimensionally mimics the 6.5 Rem Mag. This is how they stack up:

They’re nearly identical. I feel with good brass, a standard-length action which doesn’t require deep seating, premium bullets, and a good barrel, the forlorn 6.5 Rem Mag can be capable of decent accuracy. Like dad’s, mine will have a 24” barrel. More to come.

6.5 Rem Mag formed from 7mm Rem Mag.

Inside the barrel of dad’s 6.5 Rem Mag. Notice all the radial chatter marks? Those may or may not be the cause of poor performance, but they don’t help accuracy.

-Lee

www.singleactions.com

"Chasing perfection five shots at a time"