|

|

Post by Lee Martin on Oct 19, 2022 18:09:14 GMT -5

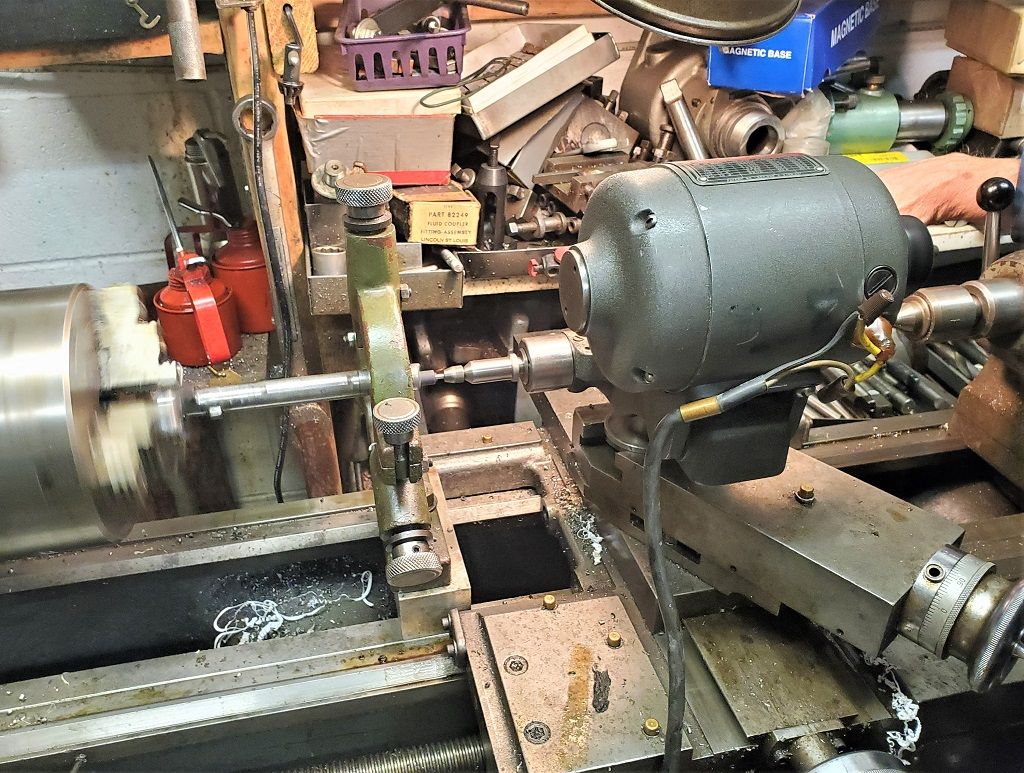

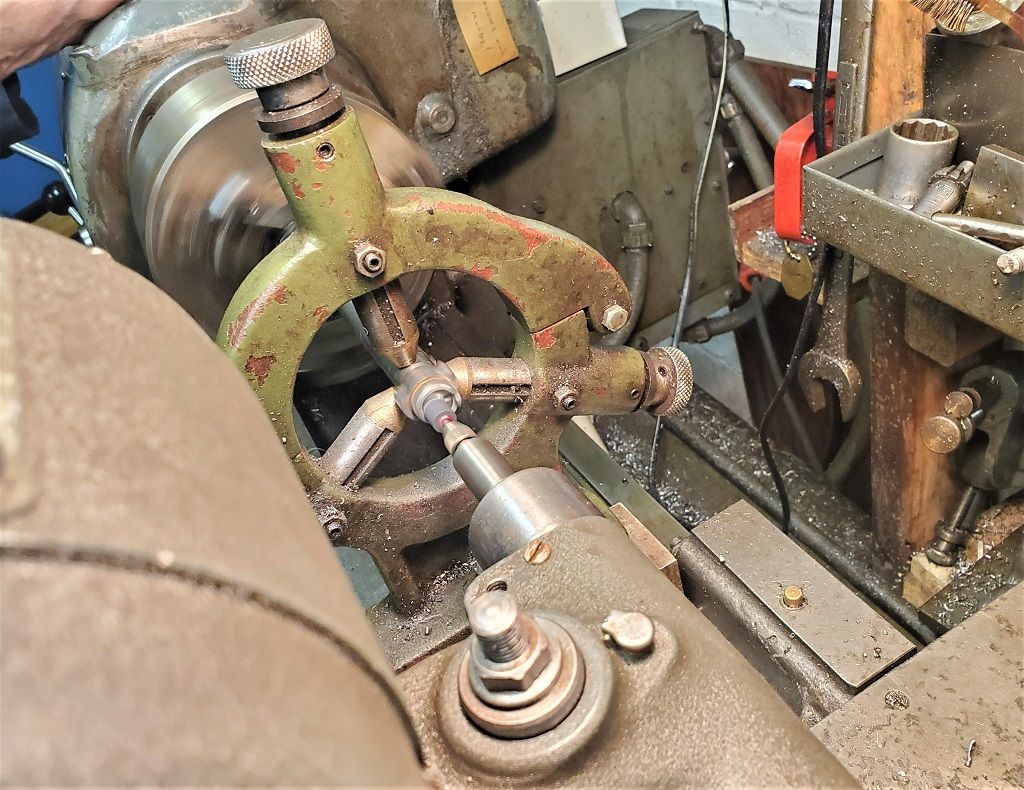

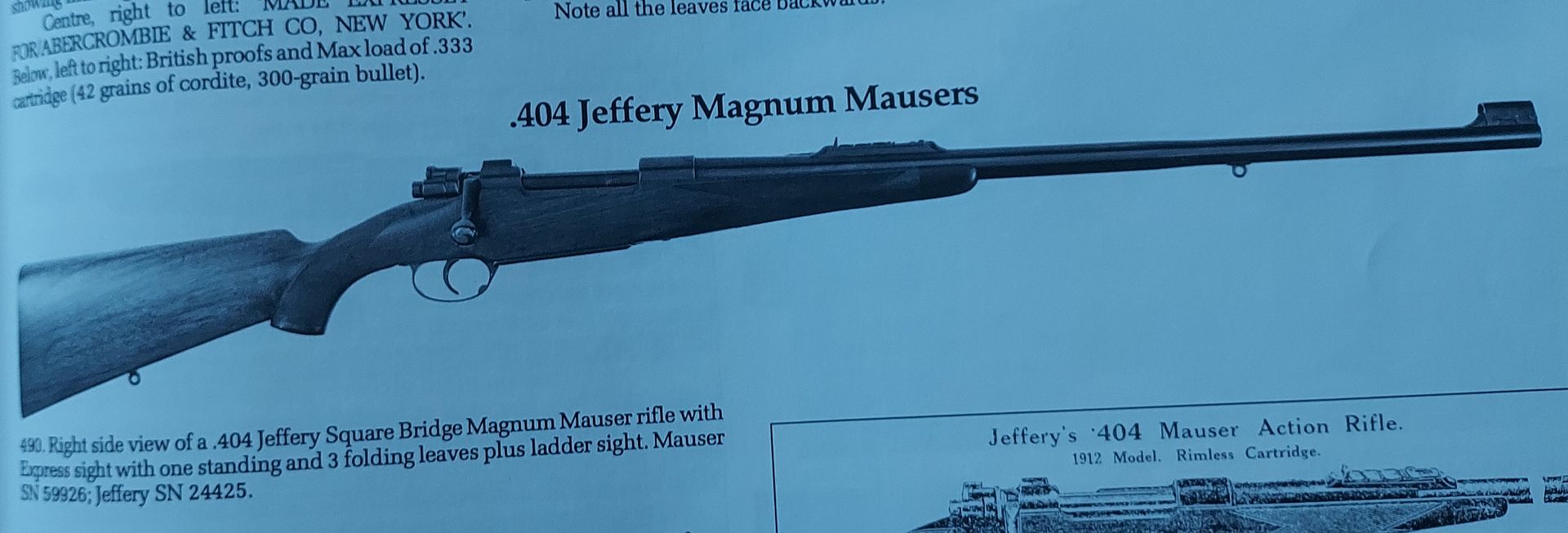

The Action I almost used a 1909 Argentine Mauser 98 for this build. However, Dad talked me out of it. The thing was way too clean to cut up. I doubt it had ever been issued. For being 113 years old, there was little to no wear. I mean, not even a ding. Instead, he went to his box of Mauser 98 actions and pulled a 1908 pattern that was in excellent condition. The year really grabbed me. The .404 Jeffery was designed in 1905, but rifles really weren’t assembled for sale until 1908. That made using a 1908 Mauser 98 all the sweeter. Plus, the Berlin made Deutsche Waffen und Munitionsfabriken (DWM) 98’s are known for being some of their best. Right up there with the CZ 24’s and Argentine 1909’s.     Step one was truing the main ring in a lathe using a mandrel my dad machined to hold them. The surface was quite clean and only took a couple of skim passes.  I then used a tool wrapped with emery cloth to polish the raceways. You’ll notice the action has already been drilled and tapped for Weaver bases (good chance my dad did this years ago. Either way, they’re straight).  Using Clover compound, I lapped the lugs. A fixture my dad made holds the bolt against the lug abatements. This took 20 minutes or so and, in the end, yielded good contact.  A lathe mounted grinder was set-up to open the bolt face for the Jeffery’s 0.543” rim.   We won’t grind the extractor until the gun is set-up for feeding. Next, we’ll cut off the bolt handle, machine a new one, and TIG weld them together. Beyond that, there’s the magazine box and feed rails to tackle. The trigger will also get replaced with a Timney. -Lee www.singleactions.com"Chasing perfection five shots at a time" |

|

|

|

Post by jfs on Oct 20, 2022 12:56:16 GMT -5

I once purchased a Ruger m77 mkII in 06 for the purpose of having a 400 Whelen built. That project was never completed and my I gave my cousin in Maine the rifle, unlike the 404 that you will eventually finish.... My mind pictures a classic sporting Mauser when I think of a 404.....

|

|

|

|

Post by richard on Oct 23, 2022 10:25:01 GMT -5

Not many cartridges have poetry written about them.

A poem by

Lon Paul

credited to Podraza

It rested between the Ivory

That hung on Grandpa's wall

It's finally checked and yellowed

Like the tusks it helped to fall

It's barrel smooth and polished

From a hundred bearers hands

It reflected the light warmly

Like campfires flickering brands

The stock of English walnut

Chewed and clawed a bit

It still showed a trace of checkering

an a dent where a horn had hit

Stamped on the barrel lightly

Was a name and not much more

A single word "Jeffery"

"Jeffery .404"

If that rifle could only talk

And take us back once again

With grandpa in Africa

A time of Buffalo,Elephants and men

But that day has set it's sun

And the rifle speaks no more

Oh what I'd give for one last time

To hear it's mighty roar

Grandpa's "Jeffery"

His "Jeffery .404"

It will be interesting to watch how you wrap a gun around the “Jeffery”.

|

|

|

|

Post by nolongcolt on Oct 23, 2022 12:31:03 GMT -5

This will be fun to watch. I have owned two such caliber rifles, a custom No.1 Ruger and a CZ 550 magnum. Both extremely accurate rifles.

I also had a Ruger No.1 in .450-400 which is basically the rimmed version of the .404, but it kicked the daylights out of me so it went down the road.

|

|

|

|

Post by bigbrowndog on Oct 23, 2022 16:07:24 GMT -5

Simply for the purpose of leaving wood in the grip for strength, I recall reading of smiths using Mausers keeping the military trigger and simply smoothing the surfaces and removing the two stage first hump. I have a Carl Gustav m96 that keeps the factory military trigger done this way and it is quite satisfactory and useable for hunting precision.

Just a thought…….

Trapr

|

|

|

|

Post by nolongcolt on Oct 23, 2022 17:34:04 GMT -5

I actually like two stage triggers. As you say it leaves wood in that area that almost all bolt rifles develop cracks in over time when hogged out for a trigger mechanism. Cross bolts help of course, but more wood is always better than less.

|

|

|

|

Post by Lee Martin on Oct 26, 2022 17:28:09 GMT -5

The Stock Some of you are probably hoping I’ll sink $1,000 - $2,000 into an exhibition grade stock. But I’m just not into ‘best quality’ guns. My eyes, and wallet, take much more to a clean, utilitarian look. For me, the stock’s strength and shape are more important than its appearance. I’ve used Boyd’s laminate stocks on many of my rifles, to include a .450 Ackley which has stood up to that level of recoil beautifully. Why I chose Boyds: 1) They offer a wide variety of designs and materials. Their laminates are proven to withstand dangerous game rounds (do a search on AfricaHunting.com) 2) Boyds uses cross bolts on all their stocks. For years, I thought the circles on the side were faux. They’re not. Two cross bolts are underneath 3) They’ll add a Pachmayr Decelerator for about the same price as me buying one and mating it myself 4) Their stocks are fully inletted and finished. Only minor sanding of the action area is required, plus the down cut for the bolt handle. I will have to open the barrel channel for the #6 contour. I’ve done this on 5 or 6 of their stocks and it doesn’t take long 5) Boyds have some nice options like forend and grip caps 6) You can choose the length of pull. I ordered their Platinum model in nutmeg laminate. Impregnated laminate is tough as hell and isn’t prone to splitting like natural woods. I also had them add a black forend cap, a black grip cap, and a 1” Decelerator pad. Because they already open the trigger area to take larger assemblies like the Timney, I’ll replace the factory trigger. Beyond that, we’ll install aluminum pillars and bed the action with steel Devcon. The barrel will free-float. Here's the stock, which arrived 9 days after I placed the order.  -Lee www.singleactions.com"Chasing perfection five shots at a time" |

|

jpw480

.30 Stingray

Posts: 140

|

Post by jpw480 on Oct 27, 2022 0:20:26 GMT -5

Lee that looks like the old JRS stock i notice it does not have the grooves on the forend that they put on the classic i'm going to have to order one those i like it

|

|

|

|

Post by junebug on Oct 27, 2022 4:06:05 GMT -5

Lee

Do the Boyds stocks have enough drop, castoff for comfortable open sight, use or will this be a red dot or scope gun only. I have had a couple of guns that were near impossible to get on the open sights for me, and damn painful to shoot when I did. Love following your builds, Thanks for taking the time and effort documenting your builds.

|

|

|

|

Post by squawberryman on Oct 27, 2022 7:25:16 GMT -5

What is the function of the two crossbolts? Does something attach to them?

|

|

|

|

Post by bradshaw on Oct 27, 2022 7:30:17 GMT -5

Lee Do the Boyds stocks have enough drop, castoff for comfortable open sight, use or will this be a red dot or scope gun only. I have had a couple of guns that were near impossible to get on the open sights for me, and damn painful to shoot when I did. Love following your builds, Thanks for taking the time and effort documenting your builds. ***** I wouldn’t want drop in the comb under serious recoil. It took centuries to wean from the fiercely dropped combs of the flintlock era. Outlandish as Roy Weatherby was in promoting velocity, the exaggeration of his comb contours, which drop the comb from your face as the rifle recoils, are a welcome safeguard to longevity of your teeth & gums in rifles such as the .378 Weatherby. I had Ben “Bear Man” Kilham made a receiver bridge aperture for a FN Mauser 7mm Mag, the stock a beautifully fast configuration with rollover comb----which drops away from your cheek on recoil, an exceptional offhand rifle with carbine handling. I know men who wear dentures from a life of trap shooting. Better to study CONSERVATION of ANATOMY before short term shock becomes CHRONIC WEAR. Over on the revolver side, this is an important principle of Ronnie Wells’ grip frame developments. David Bradshaw |

|

|

|

Post by bradshaw on Oct 27, 2022 7:35:29 GMT -5

What is the function of the two crossbolts? Does something attach to them? ***** Resist stock splitting. Also note, original Mausers have clearance between the wrist of the stock and the inletted receiver tang. To prevent splitting behind the tang. David Bradshaw |

|

|

|

Post by Lee Martin on Oct 27, 2022 10:48:07 GMT -5

junebug - I've used this stock with open sight rigs and have no problem getting aligned on the irons. This build will have a NECG Masterpiece rear and front ramp with gold bead. It'll also been scoped with a low-power Leupold in quick detach rings. jpw480 - this Platinum is very similar to the old JRS stock. As you noted, this has a full width forend. The Classic has some relief towards the top. Here's a Boyds Classic on my 9.3x62 Mauser:  squawberryman - Bradshaw is correct. The cross bolts are installed transversely through the stock behind the front receiver ring and behind the trigger slot in the rear. These bolts dissipate recoil across the width of the stock, preventing it from isolating at a weak point in the wood (which can cause splitting). Boyds drills the stock, epoxies the bolts in, and glues plastic caps on both ends for appearance. -Lee www.singleactions.com"Chasing perfection five shots at a time" |

|

|

|

Post by lar4570 on Oct 27, 2022 22:08:48 GMT -5

On my 470NE double build, I drilled a 1/4" hole down through the wrist and epoxied a piece of all thread in place to reinforce it.

|

|

|

|

Post by Lee Martin on Nov 3, 2022 18:34:23 GMT -5

The Bolt Handle & Magazine Box Stock Mauser bolt handles aren’t much in the way of looks. My dad machines his own for all of our Mauser 98 conversions:  The handle is set in a Bridgeport at 25 degrees and a flat is milled:  Dad cutting off the old handle:  A home-made jig holds the body and handle together for welding:  TIG welding the handle:  Welded up and rough filed:  The bolt is then held in a bending jig, heated with a torch, and bent with a piece of square stock. The bend puts room between the handle and stock for easy access:  View of the bolt in the action. The handle still needs to be filed some more and polished:  Like the original Jeffery rifles, I decided to cut the magazine side walls and front edge out. The rounds will ride against the inside of the stock, which will be sanded smooth. The front edge of the stock’s magazine well will be milled ahead 0.30” (but not all the way through. We don’t want the relief cut to show through on the bottom of the stock. The inletting will go down to the top of the bottom metal). Magazine marked for cutting:  Dad cutting away the sides with an abrasive disc:  The bottom metal with the walls removed. I still need to dress all of the edges:  -Lee www.singleactions.com"Chasing perfection five shots at a time" |

|