|

|

Post by tinkerpearce on Jul 9, 2021 11:35:05 GMT -5

Thanks- an excellent overview/review. Well done.

|

|

rvolvr

.30 Stingray

Posts: 298

|

Post by rvolvr on Jul 9, 2021 18:51:15 GMT -5

I hope Mr. Bradshaw didn't shoot his laptop. If'n he did, you can bet that's where he was aiming. And from 200 meters. |

|

rvolvr

.30 Stingray

Posts: 298

|

Post by rvolvr on Jul 9, 2021 20:02:24 GMT -5

|

|

pacecars

.401 Bobcat

Posts: 2,881

Member is Online

|

Post by pacecars on Jul 10, 2021 13:44:20 GMT -5

Thanks for the review. I haven’t put a lot of rounds through my 6 inch yet but what I have so far it shoots well. Trigger pull is great in double and single action and accuracy seems very good

|

|

|

|

Post by Lee Martin on Jul 29, 2021 17:22:00 GMT -5

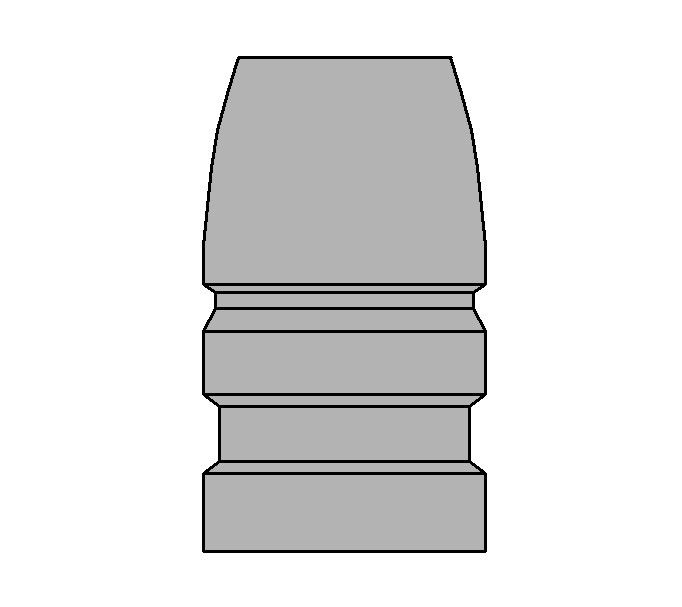

I've always wanted to try Accurate Mold's 36-158V design. This 2020 Python moved me to order one from Tom.  While I'm waiting for that, there are two other bullets I plan on shooting in it. The 194 gr Bradshaw-Martin is one. The other is Lyman's old 358311.  It may not be ideal for defense or hunting, but it's one of the most accurate .38-caliber bullets I've ever shot. It was designed for the .38 Special and saw a lot of duty in service guns. In .357 Magnum brass, you have to crimp over the driving band. I apply a mild taper crimp just under the top edge. I'm going to shoot these through the Python this weekend at 50 and 100 yards. I'll post the results. -Lee www.singleactions.com"Chasing perfection five shots at a time" |

|

|

|

Post by bradshaw on Jul 29, 2021 18:33:31 GMT -5

The "PYTHON TAPER” caper....

Believe I wrote this up a few months ago. I have to dig up notes to recall the Colt man's name.... Ben Bear Man Kilham aimed to introduce a former Colt engineer and expert firearms witness and this shooter. To this end Kilham invited us to converge on his house in Lyme, New Hampshire. A day to jawbone guns. This retired engineer watched one particular mechanic at Colt ream or hone a VERY SLIGHT taper in the drilled hole of the Python barrel. The engineer didn’t quite grasp at the time or remember exactly how the bore was tapered; the man used “a piece of wood” to achieve the taper, possibly affecting the reamer or hone. When he left Colt, his process departed with him.

TAPERED BORE, STRAIGHT GROOVE

Having finished the bore with .001 or .002 or .003-inch taper from barrel face to crown, the barrel is then clamped and a RIFLING BROACH with little teeth along its shaft pulled through in the same direction the bullet will travel----its little teeth progressively cutting grooves. The unknown Colt mechanic makes a Python barrel with tapered bore. While the grooves maintain same diameter one end to the other. Until I sat with Ben Kilham and this man from Colt (Ben Kilham had worked at Colt, also), I had never heard a plausible explanation for the Python’s “tapered rifling.”

According to the engineer from Colt, there is no such thing as “tapered rifling” in a Python. Some have a TAPERED BORE.

As Lee Martin cautions, one must be careful not to assert a tapered bore is more accurate than a straight bore. Against that, irregularity in bore & groove diameter dooms accuracy. And for sure, alternating tight and loose spots doom accuracy.

David Bradshaw

|

|

rhino

.30 Stingray

Posts: 213

|

Post by rhino on Jul 29, 2021 23:20:59 GMT -5

Why and how would a choke be installed? Not that kind of choke, bore has a taper that causes it to be more constricted “choked” at the muzzle. To help get it warmed up in winter perhaps? |

|

|

|

Post by Lee Martin on Jul 30, 2021 10:06:14 GMT -5

David - I dug through some old articles I have on Harry Pope. Think I figured out how they tapered the bore. And you're right, it involved a wooden dowel. Here are the steps: 1) The blank is drilled. 2) A long wooden dowel was turned to precisely fit the bore. The front section was turned smaller than the bore (ie, the rest of the dowel). The smaller length is typically 1.0" or so in length. 3) The dowel is re-inserted in the bore with the smaller end pushed flushed to the end of the muzzle. 4) The barrel was heated and molten lead was poured into the muzzle end. It only went as far as the transition from the small diameter to the full bore portion of the dowel. When the barrel cooled, the entire dowel assembly with lead casting was pushed out breech to muzzle. 5) The lead sleeve was pulled off the dowel. A groove was cut into the lead around its circumference. The lead sleeve was then slid onto a steel rod and held in place by a bolt that passed through the sleeve's center hole. It screwed into the rod. Much like a cleaning rod. 6) The sleeve was then rolled across a plate which contained lapping compound. The lap soaked lead sleeve was then run into the breech end of the barrel and passed back and forth multiple times. The key is it was stopped 2 to 3 inches before the muzzle exit. When then lead sleeve came back through the breech end, it was never completely removed. Instead it was exposed just enough to add more lapping compound. The groove they cut, which spanned the full circumference, held much of the lap. 7) How much they passed the lead sleeve back and forth depended on how much they wanted to choke the bore. 8) The barrel was then rifled. Again, I'm not convinced this really improves accuracy. There are some barrel makers that'll lap taper into the lands. I've seen Krieger barrels which choke by a couple of ten-thousands at the muzzle. But that's on the lands. To me, imparting taper in the bore seems like opening pandora's box. If the lead lapping isn't consistent throughout, you'll induce loose/tight spots. -Lee www.singleactions.com"Chasing perfection five shots at a time" |

|

|

|

Post by eagle1899 on Aug 8, 2021 9:49:46 GMT -5

Lee, Any updates on the Python?

I'd really like one of these and the new Anaconda. A review from you would probably push me one direction or the other.

|

|

|

|

Post by flyingzebra on Aug 8, 2021 11:53:11 GMT -5

Lee, Any updates on the Python? I'd really like one of these and the new Anaconda. A review from you would probably push me one direction or the other. I think Taffin had or has one, and you can find his comments here somewhere on the Anaconda |

|

|

|

Post by Lee Martin on Aug 9, 2021 9:05:42 GMT -5

Lee, Any updates on the Python? I'd really like one of these and the new Anaconda. A review from you would probably push me one direction or the other. Most of my opinion on the new Python can be found in the first post of this thread. I did get it out for a second time last weekend though. Using the 160 gr Lyman 358311, I shot offhand on a steel plate at 50 yards. The gun grouped tight. As long as I was steady, it would put five shots into 4 - 5". Again, that was offhand. I'm sure I could shrink that in half bench rested. I'll see how it does at 100 yards soon. -Lee www.singleactions.com"Chasing perfection five shots at a time" |

|

|

|

Post by Lee Martin on Dec 10, 2021 15:13:39 GMT -5

|

|

|

|

Post by mlazarus5388 on Dec 11, 2021 12:44:49 GMT -5

|

|

|

|

Post by pbcaster45 on Dec 24, 2021 8:19:26 GMT -5

I thought the single action was a little heavy on mine (the double action was outstanding!) but it has improved A LOT as I've shot it. Guess it just needed a little break-in. Here is a 30-foot group with the plated bullet load I use in my Clark PPC Revolver.  Bullet: Berry’s 148 gr. Copper Plated DEWC Powder: Hodgdon Titegroup 3.4 grs. Primer: Federal 100 Case: Federal .38 Special LOAL: 1.235 (Taper Crimp) |

|