|

|

Post by 2 Dogs on Nov 12, 2016 12:58:13 GMT -5

And I get to do the clean up. Ready to polish.  |

|

|

|

Post by 2 Dogs on Nov 12, 2016 13:00:00 GMT -5

The other side...  |

|

|

|

Post by 2 Dogs on Nov 12, 2016 13:08:39 GMT -5

The topstrap, and then compared to the No5.   |

|

|

|

Post by 2 Dogs on Nov 13, 2016 13:02:59 GMT -5

Ok, sometime back I posted about a fellow who took light years off this project. SteveW, thank you very much. We were very concerned that we were going to have to build a 3 leaf rear from scratch. However Steve came to the rescue and furnished a very fine 3 leaf rear sight that is amazingly crisp and positive. I can barely wait to get my prize dovetailed into the topstrap of The One.   |

|

|

|

Post by 2 Dogs on Nov 13, 2016 13:10:50 GMT -5

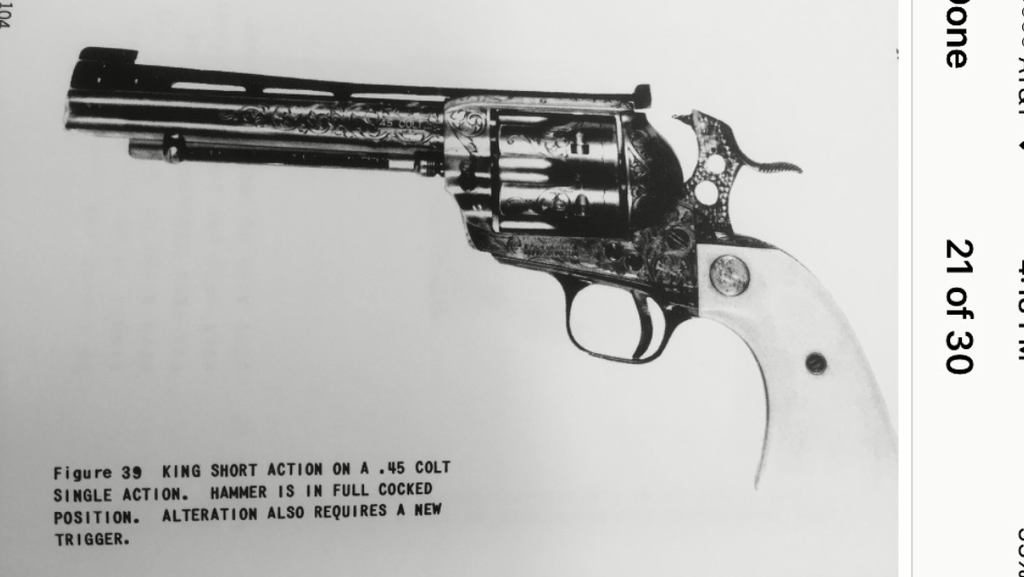

The KSA will require the existing hammer notches to be welded over, relocated, and recut. I did not want to take a perfectly good and expensive Clements Bisley hammer and experiment on it. Again, a forum member came to the rescue. TimP, thank you very much. Tim provided me with a Ruger OM hammer with damage to the notches. This is going to get a bit interesting as now not only to we have to work over the notches but we also have to weld up a Bisley hump to include a hammer travel stop and graft on a from scratch Bisley spur. We also have lighten our hammer as per Keith. Definitely traveling the old trails now. Here is a picture of a KSA sixgun with a lightened hammer.  |

|

|

|

Post by 2 Dogs on Nov 13, 2016 13:18:15 GMT -5

I am going to see about lightening the project hammer without drilling holes like this one. Gotta be a better way. Mike Barranti has suggested I send it out to SSK for EDM plunge cutting to hide the lightening cuts. What do you guys think? The last light weight skeletonized hammer I did almost nobody liked.... I rotated the picture above in photobucket to the right. I hope it rights itself. I wouldn't want Dick Thompson to crane his neck... Also, look at the Bisley spur on the KSA sixgun. Note that it is very slim and trim. Neat stuff.  |

|

|

|

Post by sixshot on Nov 13, 2016 13:25:03 GMT -5

Following this really close, both on the forum & on the phone, and there's no "crane" in my neck.

Dick

|

|

|

|

Post by 2 Dogs on Nov 13, 2016 13:39:50 GMT -5

Following this really close, both on the forum & on the phone, and there's no "crane" in my neck. Dick You always gotta watch some guys. Shenanigans!  |

|

paulg

.375 Atomic

Posts: 2,420

|

Post by paulg on Nov 13, 2016 14:01:21 GMT -5

I'm no machinist, I'm really not even close to qualified to have any input on your project. I will say though that when you mentioned wanting to lighten the hammer without drilling the holes the first thought that crossed my pea brain was exactly what Mr. BDoc Shuckenstein suggested. Just to add, I liked your sleletonized hammer on your other project. I must be a weirdo or something if I'm in the minority on that. Or maybe just a deplorable. :-).

|

|

|

|

Post by 2 Dogs on Nov 13, 2016 14:06:10 GMT -5

I'm no machinist, I'm really not even close to qualified to have any input on your project. I will say though that when you mentioned wanting to lighten the hammer without drilling the holes the first thought that crossed my pea brain was exactly what Mr. BDoc Shuckenstein suggested. Just to add, I liked your sleletonized hammer on your other project. I must be a weirdo or something if I'm in the minority on that. Or maybe just a deplorable. :-). Well, another way to look at this is that in my safe is one of the ultra rare Ruger Flattop 7 1/2" 44 specials that will probably do anything this project will. There isn't a sensible thing about it.... |

|

Fowler

.401 Bobcat

Posts: 3,670

|

Post by Fowler on Nov 13, 2016 14:40:47 GMT -5

Well the thought I have for skeletonizing the hammer is with a wire EDM you could cut the weight out of the center of the hammer body laterally. Looking at the hammer from the side you would see anything different (allowing a bit of engraving to go there as well) but the center of the hammer could be cut away in line with the barrel, the weight and momentum of the hammer and hammer face wouldn't be effected so you shouldn't ignition issues from the lighter hammer. There is a 1911 "speed hammer" offered that Doug Koenig used to push that had the middle cut away in a similar manner.

Also could EDM the back of the hammer to add the Bisley hump after the weld up at the same time.

Just pondering aloud here you understand...

|

|

|

|

Post by mike454 on Nov 13, 2016 14:49:11 GMT -5

Drilling the face of the hammer was the solution that I've seen mentioned a few times by the old time writers including Lachuk, and I believe Elmer as well.

|

|

|

|

Post by 2 Dogs on Nov 13, 2016 14:53:50 GMT -5

Might could be done with a carbide mill cutter...

We are going to find out!

|

|

|

|

Post by BigBore44 on Nov 13, 2016 14:54:23 GMT -5

[quote [/quote]Well, another way to look at this is that in my safe is one of the ultra rare Ruger Flattop 7 1/2" 44 specials that will probably do anything this project will. There isn't a sensible thing about it.... [/quote] I reckon if'n it was easy everyone would be doing it or have one. Now what fun would dat be?  Lookin good buddy. I mean the gun. Not sure about Dick's neck?  BigBore44 |

|

JM

.375 Atomic

Posts: 2,454

|

Post by JM on Nov 13, 2016 15:02:34 GMT -5

How difficult would it be to remove a certain depth of material from each side that follows the hammer's contour, yet leaves the center remaining? Somewhat like a skeletonized hammer, but the material in the center remains. Hope I was able to explain properly. PS. How long do you think your project will retain its status as: "The One" ?  |

|