|

|

Post by Lee Martin on Dec 19, 2016 19:56:51 GMT -5

A split collar was lathed to hold the brass for trimming. First, we center drilled and reamed it undersized:  The chambering reamer is run in to approximate case taper:  Cutting the brass to length:  Bertam basic at 3.10” is too long to go into the FL sizer. The mouth actually gets into the die’s internal threads. Step 1 is to cut the brass to 2.90”. Next, full-length sizing sets the shoulder and then the last 0.10” is turned. A photo of completed Nyatis and the collar:  The stocked rifle also arrived and it tops expectations. Wenig used stout, but beautifully figured high grade English walnut. I’ll shoot it this weekend without sights to check function. The starting load is 130 grains of 4350 and a 750 Woodleigh. That should duplicate top .577 Nitro yet still be 30 grains under max. If all goes well, I’ll add a NECG express rear and front ramp with a gold bead dovetail. Look for photos in a week or so. -Lee www.singleactions.com"Chasing perfection five shots at a time" |

|

|

|

.585 Nyati

Dec 19, 2016 23:58:21 GMT -5

via mobile

Post by Quick Draw McGraw on Dec 19, 2016 23:58:21 GMT -5

I'm excited for some pics and an update, but Holy Water Buffalo! 130 grains s of powder?! I'm officially not complaining about the 30 or so grains I put in my .454 Casull. Also, tell us about the recoil as I imagine it will be quite monstrous. How many rounds do you think you could handle in one sitting? I can handle my big bore revolvers all day, but 20 rounds of .30-06 and I am done! Granted that rifle is like 7.5 lbs.

|

|

mtngun

.240 Incinerator

Posts: 12

|

Post by mtngun on Dec 20, 2016 22:04:16 GMT -5

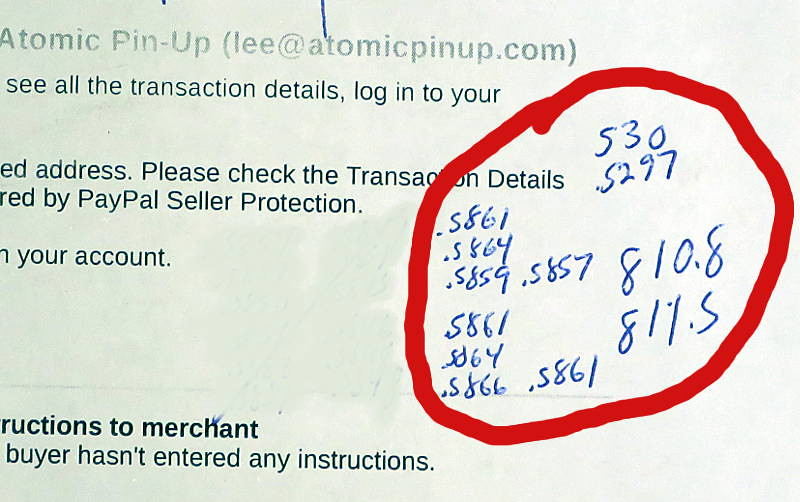

my arbor press and die size the 800's with very little arm. I haven't had a need to switch, especially when I'm casting low quantities. -Lee www.singleactions.com"Chasing perfection five shots at a time" Lee, as always I appreciate your detailed "how-to's".  I pick up a new trick or two every time I read one of your build threads. You have already found a solution to your bullet sizing problem, so I'm beating a dead horse, but it just doesn't sound right to me that you can't size the bullets in a push-thru die on the reloading press. With a proper die, sizing should only require modest effort, even with 45 BHN bullets, never mind 21 BHN. The sizing difficulty you describe suggests to me that the die could be improved. Sizing dies should have a generously and progressively tapered entrance. Something like this: The first 1/10" is a generous chamfer, then the next 3/10" is a gradual taper to the final diameter. A good die squeezes the bullet, rather than scraping it. After machining the bevel and taper, use a hone (a brass rod or hardwood dowel that has been slitted to hold a wrap of emery cloth) to knock the sharp edges off the tapers and to sneak up on the final bore size (unless of course, you are lucky enough to have a Sunnen hone to sneak up on the final bore size  ). You mentioned that the bullets were dropping 0.5885". I pulled my notes for your mold and when I tested it, it dropped out 0.5857" - 0.5866" (you specified 0.585") and weighed 811 grains, with my linotype. At the time, I was worried that the bullets were a little on the small side! Well, it's normal for as-cast diameters to vary depending on mold temperature, casting technique, etc., but .... you might check to make sure there is no lead splatter on the faces of the mold preventing the mold from closing completely. Also, did you purchase your lino from a foundry? Just wondering if maybe you got bought some scrap lino that had monotype mixed up with it?  Re: lubing the bullets. I agree with your dad that 0.586" is too big for Lyman/RCBS sizing die. But ..... and this is just speculation, because I have not actually attempted it -- I can't think of any reason that a 0.586" lubing die wouldn't work. The difference being, you would only use the lubing die to apply lube to bullets that had already been sized, so there would be very little stress on the die. You might have to leave out the o-ring groove, but that shouldn't be a big deal. At any rate, carry on.  |

|

|

|

Post by Lee Martin on Dec 22, 2016 18:18:15 GMT -5

Dan - first, let me welcome you to the forum. I'm a huge fan of your work and your knowledge is a great addition to the site. Now I must confess, I screwed-up on the aforementioned post. The bullets drop 0.5867". So I'm squeezing less than a thou when sizing. And I think you're right about the die. We reamed and honed it with no taper. We have a Sunnen and will put the suggested amount of taper into the bore. I bet that'll solve the problem. Stay tuned. As for the lino, I get mine from Zip Metals. Hardness is between 20 and 22:  Tomorrow I'll test fire the gun with 750 gr Woodleighs. Starting load is 130 of 4350. According to Ross' data, it'll go ~2,150 (which duplicates the .577 Nitro). Working up to 160 grains should net 2,500 fps.  Eventually I'll develop a reduced load with your 800 gr slug, say 1,800 fps. -Lee www.singleactions.com"Chasing perfection five shots at a time" |

|

cmillard

.375 Atomic

MOLON LABE

MOLON LABE

Posts: 1,999

|

Post by cmillard on Dec 23, 2016 9:47:19 GMT -5

oh boy!!!!!

|

|

gunzo

.30 Stingray

Posts: 423

|

Post by gunzo on Dec 23, 2016 10:30:03 GMT -5

Lee,

I suppose this seems like an after thought, but I wondered about the entrance of your sizing die when you mentioned the amount of force needed to push the bullet through. Not a bullet size die maker here, but was once, many years ago, a draw die maker in a wire mill. I think the rules would apply for any type of push or pull through sizing.

As you have stated, an entrance or forcing cone(angle)should solve the problem. It's pretty much a must have.

Now for the rifle. Hope you are taking plenty of pics & I for one would love to see a video of it being fired. How bout it?

|

|

paulg

.375 Atomic

Posts: 2,420

|

Post by paulg on Dec 23, 2016 10:55:47 GMT -5

This build gives the answer to the question "bring enough gun?"

|

|

|

|

Post by Lee Martin on Feb 6, 2017 20:05:44 GMT -5

The Nyati is done and instead of completing this thread, I wrote an article. That read can be found here: www.singleactions.com/585Nyati.htmlHopefully you'll find it enlightening. I tried going beyond your run of the mill cartridge history, load data, and sample targets. -Lee www.singleactions.com"Chasing perfection five shots at a time" |

|

cmillard

.375 Atomic

MOLON LABE

MOLON LABE

Posts: 1,999

|

Post by cmillard on Feb 6, 2017 20:59:26 GMT -5

oh boy!!!!

|

|

|

|

Post by Lee Martin on Feb 7, 2017 19:23:41 GMT -5

|

|

|

|

Post by Rimfire69 on Feb 7, 2017 20:58:19 GMT -5

Turned out fantastic as expected.

|

|

|

|

Post by Lee Martin on Dec 11, 2019 20:39:32 GMT -5

|

|

|

|

Post by squawberryman on Dec 11, 2019 20:51:54 GMT -5

Lee forgive me if it's in the last six pages but is this considered a destructive device as per NFA? Granted you didn't transfer it at the LGS.

|

|

|

|

Post by Lee Martin on Dec 11, 2019 21:06:18 GMT -5

Lee forgive me if it's in the last six pages but is this considered a destructive device as per NFA? Granted you didn't transfer it at the LGS. There are a few sporting cartridges over .50-cal which are NFA exempt. Those include the old Nitros, the .577 Tyrannosaur, the .585 Nyati, and some others. Basically, safari rifles. -Lee www.singleactions.com"Chasing perfection five shots at a time" |

|

|

|

Post by bradshaw on Dec 11, 2019 21:25:18 GMT -5

****** Lee.... pure idiocy. Built like bull, the young man may be o.k; yet not for long if he repeats that technique. Next in line, the young woman may be lucky to come away with a broken collar bone and smashed lymph nodes. Both individuals may have received “tactical” training with submachine guns, which center-hold technique works reasonably well----accuracy wise----with a chopper in 9mm or .223, albeit at expense of much body exposure. Or, it may be the Torso Wrench chiropractic method. David Bradshaw |

|