|

|

Post by Lee Martin on Apr 8, 2015 15:51:41 GMT -5

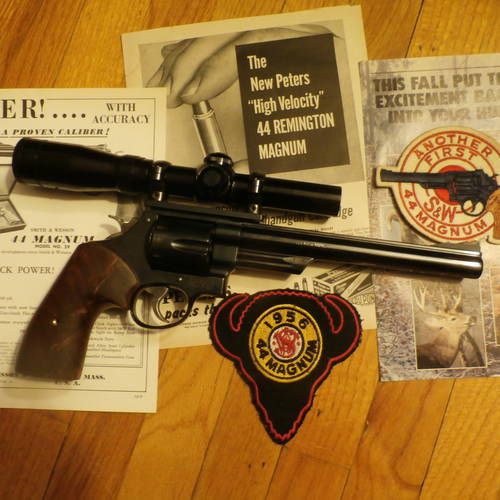

Pair of 1970's S&W Model 29's with 8-3/8" barrels. Separated by 500,000 N-frames, these revolvers exemplify Smith & Wesson quality during an era of managerial turbulence, poison which occasionally spilled out on the shop floor. These two guns represent the old timers who built them.  Blue 8-3/8" M-29 purchased in early 70's to compliment the 6-1/2" which lived on David's hip. Shooting partner Ed Verge lived with a Model 57 8-3/8" .41 Mag on his hip. Neither marksman felt in the least handicapped by his choice of barrel or caliber.  For the most part an option on S&W revolvers, the M-29 always came through with the wide Target Hammer and Target Trigger. Sharp checkering insures thumb never inclines to slip off spur.  Drop forged parts are classic S&W: include frame, barrel, side-plate, yoke, rear sight leaf, rebound slide, cylinder stop, hand, mainspring, hammer, and trigger. Hammer & trigger are case hardened and enjoy long service life, providing the parts are not stoned. S&W calls firing pin-in-hammer the hammer nose.  Before handgun silhouette came along, blue 8-3/8 M-29 spent life as a holster gun. During one visit to the factory, a narrow trigger was fitted. David fonds trigger width is less important with N-frame 6-1/2 and 8-3/8" barrels, and shoots serrated and smooth with equal ease. Trigger selection becomes more critical with 4-inch, where a serrated narrow or smooth combat works well. The wide Target Hammer & trigger are out of place on smaller K-frame Smiths.  Narrow trigger on N-frame M-29.  Width of Combat Trigger puts it between narrow and Target. Smooth face distinguishes trigger intended for double action; edges should be rounded to complete the effect.  After David joined the IHMSA in 1977, he brought the 8-3/8" 29 to the factory. The Baughman red ramp front sight was replaced by a Patridge blade.  -Lee www.singleactions.com"Building carpal tunnel one round at a time" |

|

|

|

Post by bradshaw on Nov 8, 2017 8:07:38 GMT -5

awp101.... note the blade of these M-29-2 front sights. The ramp is integral to the drop forged barrel. The sight blade itself----whether Baughman red ramp, plain Baughman ramp, Patridge/target, Partridge with Call bead flat bead or slightly beveled disk), or Partridge with McGivern bead (domed bead)----is pinned with an interference fit to a slot in the ramp.By interference fit, I mean the pin acts to pull the blade down into the slot when the pin is inserted. To remove this sight, the Smith & Wesson mechanic taps the blade with a drift----front-to-back----to shear the pin. The pin may also be driven out, but care must be taken to not mar the ramp.

The nickel M-29 with Baughman red ramp shows the pin ground flush prior to nickel plating. The pin is nearly invisible.

The blue M-29 shows with Partridge blade shows the pin with domed ends as installed in the S&W shop. Sheared pin remains in original red ramp.

As Dick Thompson advises, one must look closely to detect a flush pin. Whether blue or nickel these guns are finished with front sight in place. Some S&W ribbed barrels are straight and do not have a raised base integral to the forging. Two pins may secure such a base. A pinned base lacks the seamless curve of serrations from rib-to-base. Pins in a pinned base may be harder to detect than the pin in a pinned blade.

David Bradshaw

|

|

|

|

Post by seak89 on Nov 8, 2017 15:19:29 GMT -5

Old enough so back in the day means something. I was well into handguns by the seventies but mostly single action. It was a time you could still cross the border to Mexico with a half dozen colt 38 supers in any shape and ask around little villages and fine old Colt SA in 45 which were illegal for the people there to own,nothing bigger than 38cal but no 357mag allowed. Lots of old fine Colts found their way back to the states that way and the folks were glad to have a legal pistol something they could use not hide.

|

|

|

|

Post by jfs on Nov 10, 2017 0:52:17 GMT -5

Bought an 8 3/8" model 29 sometime in the 80`s and the first time I took it to the range I fired some factory 240gr ammo and after the first shot the cylinder unlatched and the fired round came back up.. I did not know what the heck was happening... Anyway, as time went by I purchased a 41 mag cylinder and barrel and had Austin Behlert`s son in law make the change.. Its now one of the best shooting revolvers I own... The S&W N frame seems to be a better 41 mag then a 44..

PS -that is not a 58 barrel with a ramp sight added. Its factory... Took the gun to a SWCA meeting and no one could shed any light on why a 58 barrel would have a factory ramp, pinned front sight....

|

|

|

|

Post by bradshaw on Dec 8, 2018 20:40:06 GMT -5

highplains..... Vol. 66 (LXVI) is Part 1 of a five part series----Vol. 66 through Vol. 70----on the M-29 8-3/8”. Back in the day, an M-29 was called a “Model 29.” No on ever mentioned a dash number. But then, there was nothing newer than an M-29-2. The guns in this series are M-29-2 variants.

David Bradshaw

|

|

|

|

Post by bradshaw on Dec 8, 2018 23:25:35 GMT -5

James.... straighten me out on your 4-inch .41. Did it start life as an 8-3/8” .44 Mag, which Behlert converted to .41 Mag with 4” M-58 barrel? If the gun pictured was converted by Behlert from .44 to .41, he may have used a fixed sight M-58 barrel.

Smith & Wesson would convert a Model 57 .41 Mag to .44 Mag with M-29 cylinder & barrel. Or convert a Model 29 to .41 Mag with M-57 cylinder & barrel. The owner got the original cylinder & barrel when he picked up the gun. The frame would not be over-stamped. Never asked, but doubt S&W would put an Model 58 barrel on an adjustable sight frame. And don’t know whether S&W would do these swaps today.

The cylinder unlocking under recoil, with BARREL TORQUE twisting the revolver counter-clockwise, so that you dry fire on the chamber just fired, is the condition I described to Smith & Wesson in 1979-80 as CYLINDER FLOAT.

David Bradshaw

|

|

|

|

Post by highplains on Dec 9, 2018 10:04:36 GMT -5

James.... straighten me out on your 4-inch .41. Did it start life as an 8-3/8” .44 Mag, which Behlert converted to .41 Mag with 4” M-58 barrel? If the gun pictured was converted by Behlert from .44 to .41, he may have used a fixed sight M-58 barrel. Smith & Wesson would convert a Model 57 .41 Mag to .44 Mag with M-29 cylinder & barrel. Or convert a Model 29 to .41 Mag with M-57 cylinder & barrel. The owner got the original cylinder & barrel when he picked up the gun. The frame would not be over-stamped. Never asked, but doubt S&W would put an Model 58 barrel on an adjustable sight frame. And don’t know whether S&W would do these swaps today. The cylinder unlocking under recoil, with BARREL TORQUE twisting the revolver counter-clockwise, so that you dry fire on the chamber just fired, is the condition I described to Smith & Wesson in 1979-80 as CYLINDER FLOAT. David Bradshaw |

|

|

|

Post by highplains on Dec 9, 2018 10:05:53 GMT -5

Thanks very much David.

|

|

|

|

Post by bradshaw on Oct 10, 2019 8:20:25 GMT -5

Glen and 45MAN..... M-29 with Patridge blade installed at Smith & Wesson. Note sheared pin in removed Baughman red ramp. S&W’s guru mechanic Al Plaas drove out front sight with hammer and brass punch, shearing pin. Slot in base (base integral to machining drop forged barrel) is cut in a round arc. I was surprised to see Al Plaas just bang out the red ramp! While he was at it, Al Plaas replaced M-29 white outline rear sight slide with a plain blued slide;. Checking, at the same time, for flawless micrometer-click operation.

David Bradshaw

|

|

|

|

Post by jfs on Oct 11, 2019 12:26:53 GMT -5

Thanks David for "cylinder float".. I would say "the cylinder rotated in the opposite direction after a shot was fired"... Keeps it simple.. Yes.. Behlerts son-in-law Art Leckie did the work changing from 44 to 41..... Never knew back in the day that the factory did the barrel/cylinder change.. Nothing in the world like a good single action trigger on a S&W...

|

|

|

|

Post by bradshaw on Oct 11, 2019 19:59:02 GMT -5

James..... Austin Behlert tired to save the double action on my Dan Wesson Arms M-15 at a Bianchi Cup. I had worn through the nickel plating of the powdered metal trigger and hammer., and disaster now arrived with Murphy’s signature bad timing. The double action grew heavier and heavier, like trying to plow a rock pile. “If I’d known you were coming...." exclaimed Austin. Powdered metal has come a long way since then. But, like trying to breathe life mouth-to-mouth into a dead man, the taste remains.

These old Smiths feature chamber-to-bore alignment so tight it proves, as Lee Martin notes, line-boring is not the only way to skin that cat. Don’t quite remember how much Ed Verge paid S&W to swap .41 barrel & cylinder for .44 Mag on his M-57. Thinking fifty or 60 skins each for barrel & cylinder, job complete. We couldn’t tell any difference. Chamber-to-bore runout ran to .002-inch on all six. At that time fierce quality reigned at Smith & Wesson. We had what appeared to be good eyes and shot like we meant business. I still try, as it is a great sleeping pill to shoot straight.

David Bradshaw

|

|

|

|

Post by jfs on Oct 12, 2019 12:31:33 GMT -5

$60 for a barrel cylinder change with a .002" gap is amazing....The M-29 is a classic.... Can`t imagine the things you have seen in your life.... Can`t imagine the things you have seen in your life....

|

|

|

|

Post by bradshaw on Oct 12, 2019 23:03:47 GMT -5

James.... clarification: the .002-inch refers to chamber-to-bore runout, not cylinder/barrel gap. Without looking measuring the blue 8-3/8” or digging upp notes, I’d say the cylinder gap measures .003 or .004-inch. Fortunately, however much it matters to velocity and side blast, barrel/cylinder gap has almost nothing to do with accuracy. I arrived with my own baggage----otherwise know as theories----during the period I was trying to sort out WHAT MAKES A REVOLVER TICK? Cylinder gap was one such theory I though must surely affect accuracy. Fortunately for me and thousands of others, a generous gap is one of those things an otherwise great revolver can get away with.

Smith & Wesson mechanics slipped a .006” feeler gauge through the cylinder/barrel gap and held it there as they rapidly dry fired the revolver double action. There must be no drag. Guns set tighter work fine, so long as endshake is nearly perceptible; and no yoke shake (fore-and-aft movement). Guns for cops and somnambulating citizens should not be set so tight. A mindful pro gets away with tighter because she & he pay attention to their instruments.

Elgin Gates and I had a few gritty discussions on what makes a PRODUCTION Category “production.” One of Elgin’s great contributions to IHMSA silhouette was proposal for a category for factory revolvers and pistols which must b stocks in all particulars save two: 1) trigger job allowed----factory parts only, and 2) no non-factory parts except grips finished to a standard pattern (Pachmayr the prime example). Later on, Elgin got carried away and insisted a Production gun must be fitted without file marks. Yeah, right. You won’t an assembly bench without an assortment of files and stones on it. Leastwise none I’ve seen. Not to mention Smith & Wesson and Colt revolvers were meant to be hand-fitted. Bill Ruger tried to get away from the hand fitting but could not. Now, there are some recent guns----the little plastic frame Ruger revolver----which go together without any tuning. Not the old guns.

I love a production revolver made right.

David Bradshaw

|

|

|

|

Post by jfs on Oct 13, 2019 13:16:47 GMT -5

David, Of all the people you know is there anyone who stands out above the rest??

|

|

|

|

Post by bradshaw on Oct 14, 2019 9:07:56 GMT -5

David, Of all the people you know is there anyone who stands out above the rest?? ***** IndustrialistsAmong firearms industrialists, Bill Ruger. Knowledge gained during World War II combined with a powerful design instinct in a vision to revive the civilian arms market post-war. The start, of course, his brilliant .22 Auto Pistol. His refusal to cash a check without delivering a gun, gaining public trust. The close of WW II saw American heavy industry switch from making tanks to making cars. At the same time, Colt, so intoxicated on the government tit, decided to hell with civilian sales, we’ll live off contracts. (This would do wonders for Colt profits for a limited time during the Vietnam War, when Colt shipped 50,000 M16’s per month.) Smith & Wesson stuck with tried & true old school manufacturing, while pursuing civilian sales through adjustable sight sixguns more suited to our marksmanship and ballistic requirements. Winchester remained old school, also, but couldn’t lower manufacturing costs to compete with Mike Walker’s Remington Model 700 series. Savage adjusted to the expanding civilian market in its own way. In combined talent and work, no one comes close to Bill Ruger. When Bill Ruger designed----and set to manufacturing----his .22 auto, he transformed manufacturing. Had his pistol not been so sound, so rugged, so ready to be holstered and carried into any environment, and so affordable, it would have fallen on its face. It opened the door to his Single-Six, the Blackhawk, and his 10-22, which kicked the doors off their hinges. One night at dinner, during one or another gun discussion, Bill pauses.... “My biggest mistake was to not buy Smith & Wesson for 14 million dollars.” (Or, maybe he said 17 million; it was one of those two numbers.) I paused, and bit my tongue, thinking it may have been a great thing he didn’t buy S&W.... would Ruger manufacturing crept into the Springfield factory? I could not imagine an S&W built the Ruger way, it’s just a completely different concept. Nor could I imagine a Ruger single action built at S&W with drop forged frame without exceeding Colt price. And my reservations about conglomerate manufacturing have yet to be disabused.) Bill Ruger rescued the Second Amendment after the Second World War. ShootersThe list is not thick. Yet it is thick enough I would be bound to leave someone out. Among personal influences, I might have to name COMPETITION itself above individual influences. Individual influences are not minor. Robert “Doc” Carroll and Sam Burkhalter, maestros of the M1 Garand. Their quiet yet absolutely firm encouragement of screaming performance, their trust that I would get it. Ed Verge, my shooting partner of a number of years. We met at a moment our handgun skill had plateaued----each shooting consistent high level with the magnums we wore daily. Ed with M-57 8-3/8” .41 Mag. And me, M-29 6-1/2” .44 Mag. We drove each other with a quiet ferocity. An analogy may be seen in skiing, or riding a bike down a mountain: gravity drives you, you have no choice but to hold on. Balance is liquid, like turning on a deer in the woods, drawing the revolver.... To be pulled by the target. Your only control everything you’ve learned. It’s exhausting, exhilarating, and must be done. David Bradshaw |

|